Lint hooking tool of tufting machine

A technology of hooking knife and tufting machine, which is applied in the field of hooking knife, and can solve problems such as being unable to escape from the upper horizontal edge, and being unable to produce looped pile products without cutting the pile loops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

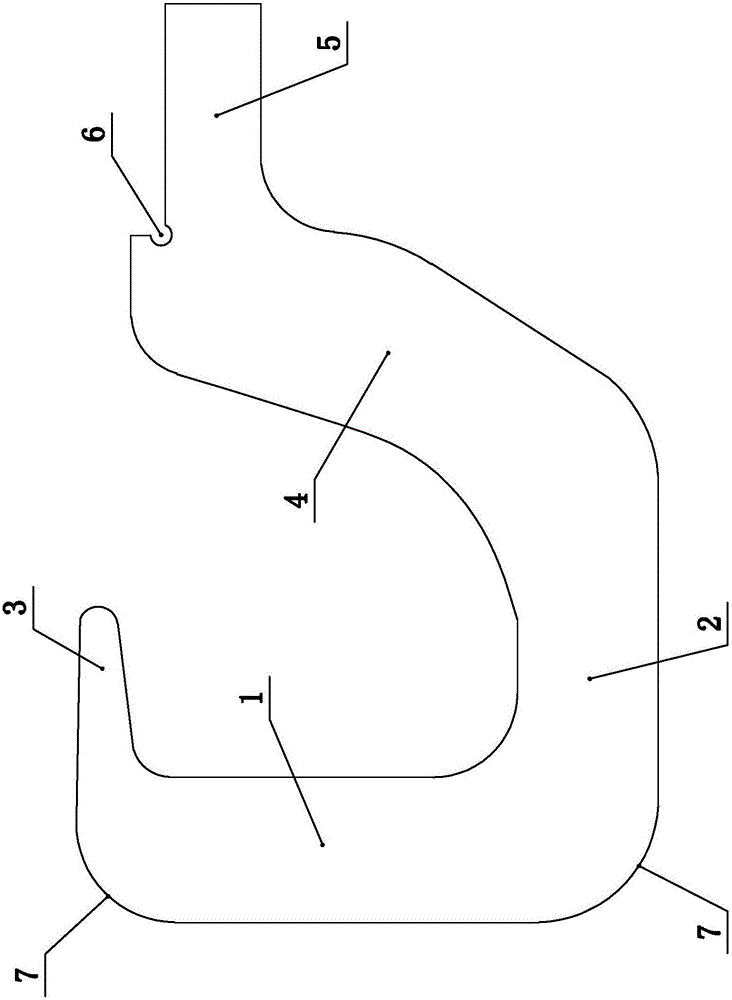

[0010] Such as figure 2 Shown is a tufting knife of a tufting machine, including a knife beam, the knife beam has a vertical section 1 and a transverse section 2, and the upper end of the vertical section 1 is bent and extended to form a The barb part 3, the lower end of the vertical section 1 is connected with the front end of the transverse section 2, the rear end of the transverse section 2 is connected with a smooth section 4 extending obliquely upward, and the smooth section 4 is connected with a backward curved Fold the extended plug tail 5. A positioning notch 6 is provided at the joint between the plug tail portion 5 and the smooth section 4 . The upper and lower ends of the vertical section 1 are rounded 7 .

[0011] With the hooking knife provided by the present invention, the barb portion 3 moves backward after hooking the pile loop, and then moves forward again to pick up the next pile loop, the hooked pile loop will take advantage of the trend from the barb por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com