Keel production system

A production system and keel technology, which is applied to other manufacturing equipment/tools, packaging, and strapping machinery parts, etc., can solve the problems of large land occupation, low production efficiency, low plant utilization rate, etc., to eliminate channels and reduce occupation. Land area, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] The essential difference between the second embodiment and the first embodiment is that a guiding mechanism is provided.

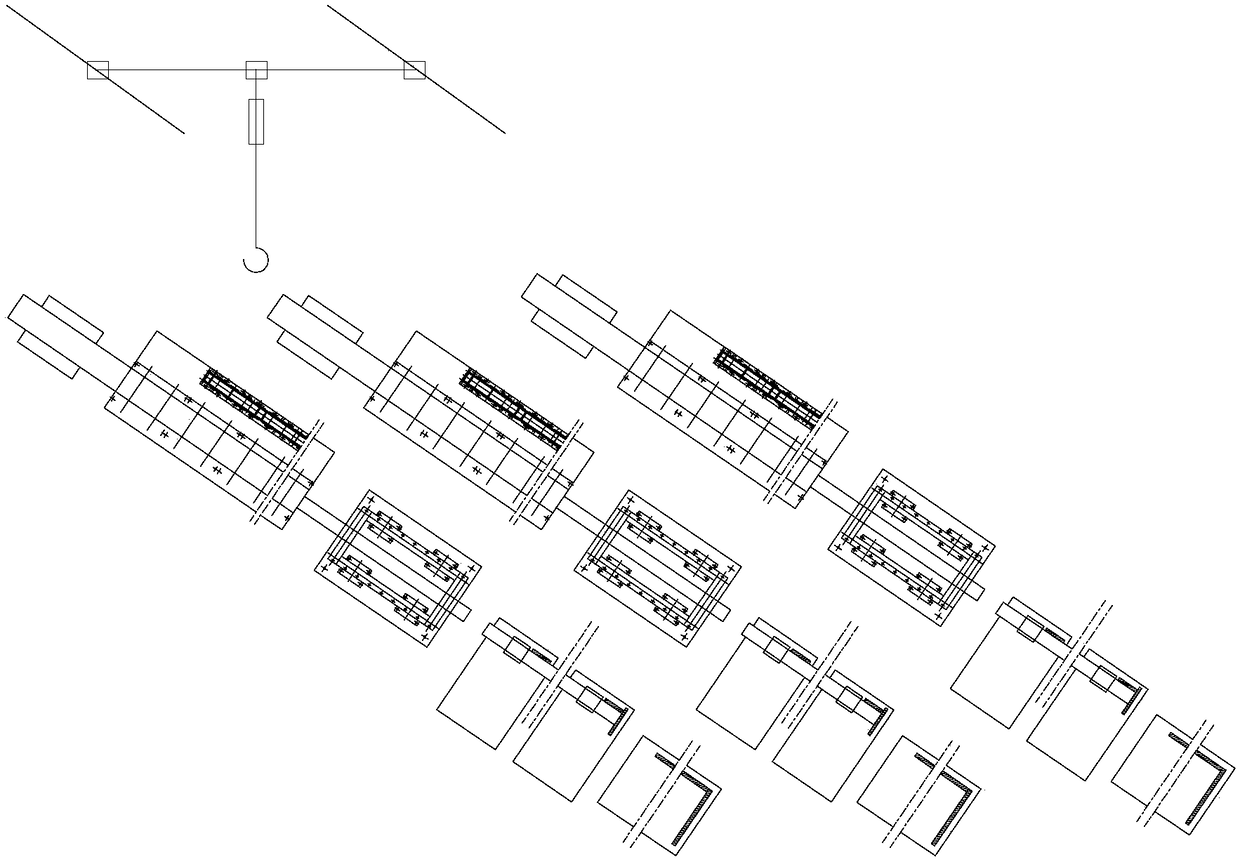

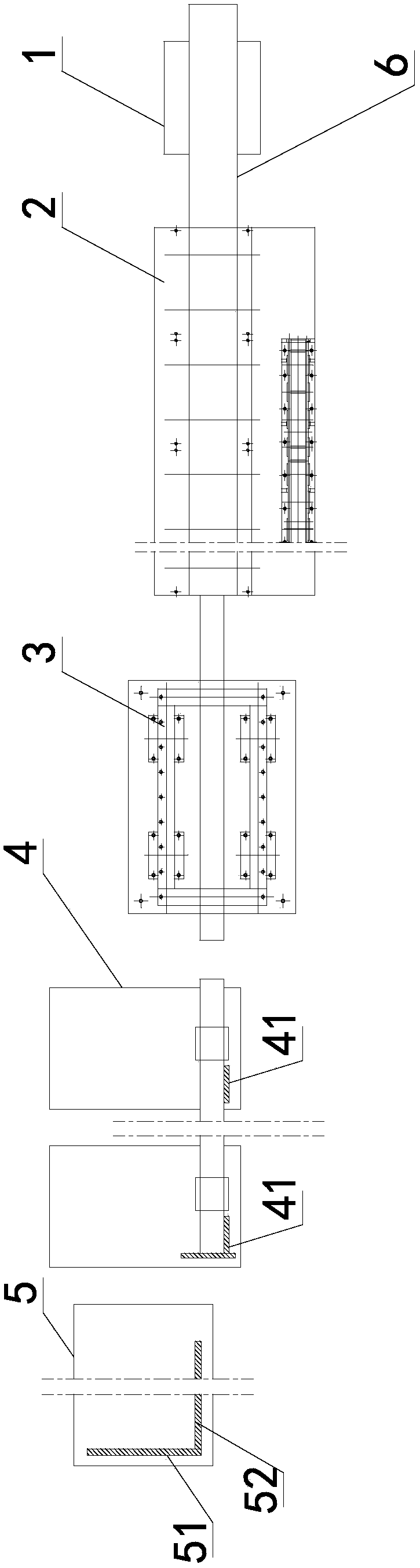

[0067] like Figure 4 As shown, the keel production system provided by the second embodiment of the present invention has a main structure similar to that of the first embodiment, and also includes a traveling vehicle, a mounting frame, a bending mechanism, a shearing mechanism, a packaging mechanism and a stacking mechanism; the specific structure records, Please refer to the description of Embodiment 1, the purpose here is to explain the difference between the two.

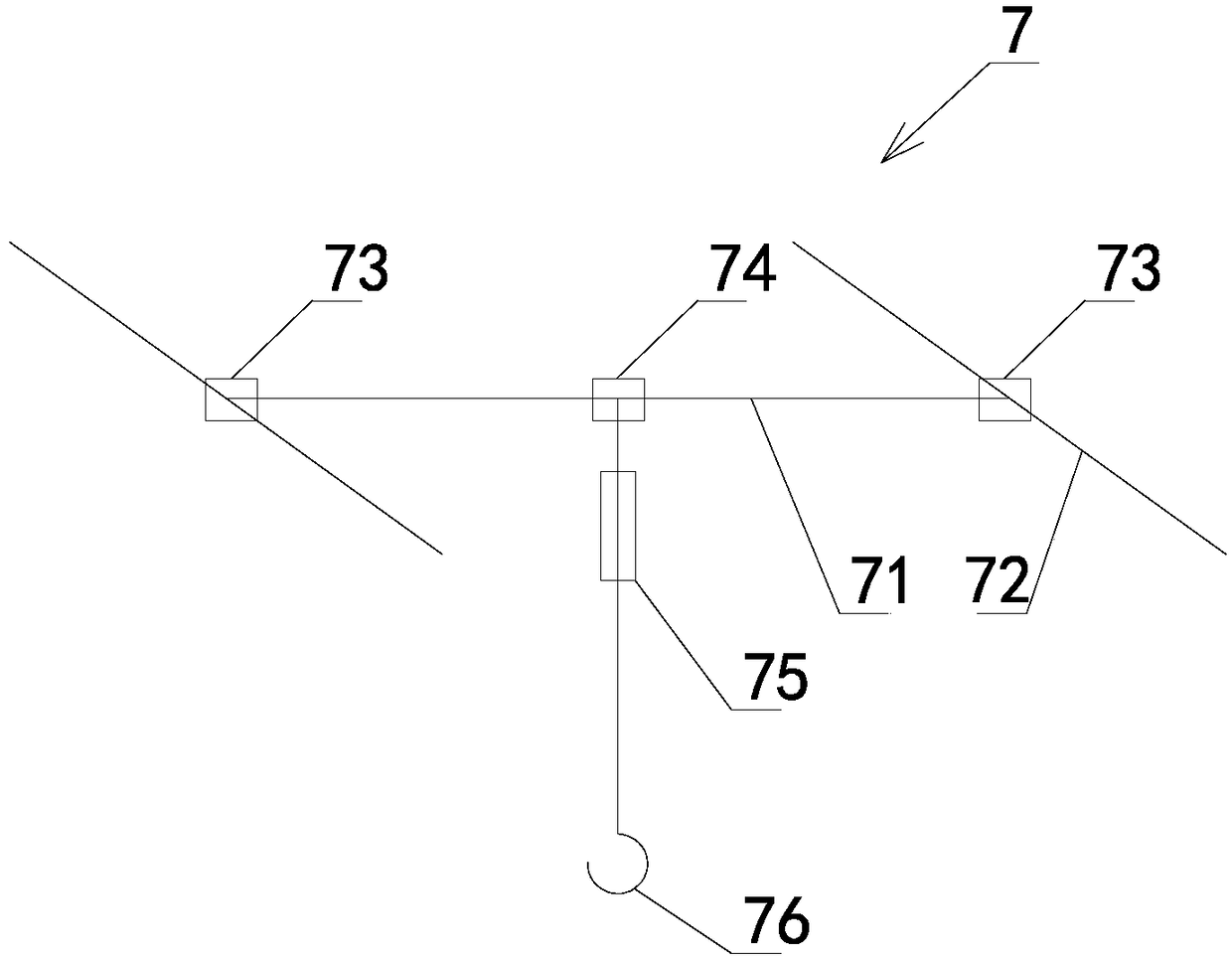

[0068] In this embodiment, the above-mentioned bending mechanism 2 may include a dragon fracture bender 21, and a guide mechanism is provided on the feeding port side of the dragon fracture bender 21.

[0069] In the specific operation, the setting of the above-mentioned guiding mechanism can realize the smooth guiding operation of the steel strip; the above-mentioned guiding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com