Anti-dropping device for hydraulic decoking system

A hydraulic decoking and anti-falling technology, which is applied in engineering emergency equipment, non-catalytic thermal cracking, mechanical equipment, etc., can solve the problems of insufficient service life of equipment, damage to decoking equipment, coke tower equipment, and enterprise safety production Risk and other issues, to achieve the effects of avoiding personal injury accidents, long service life, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

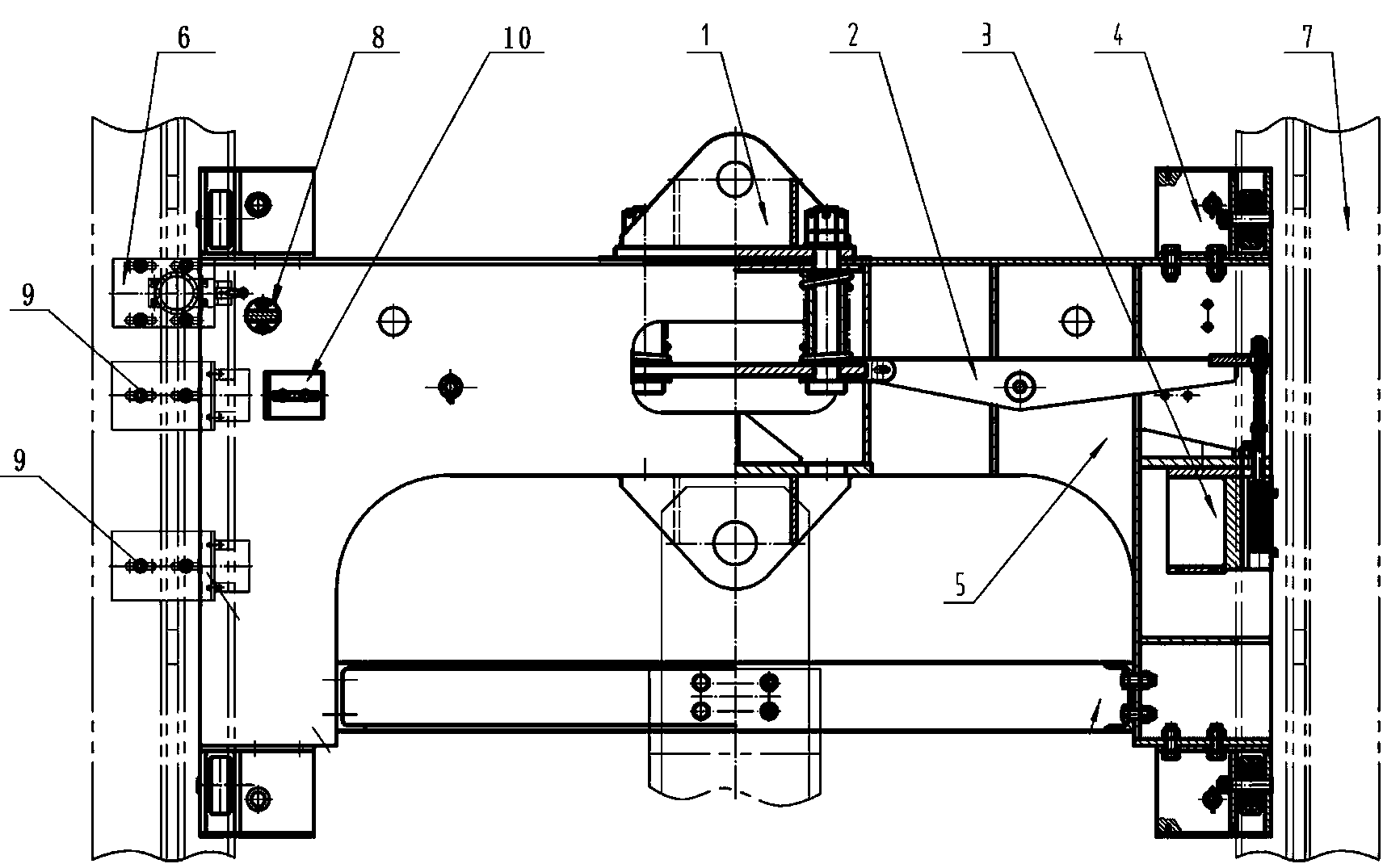

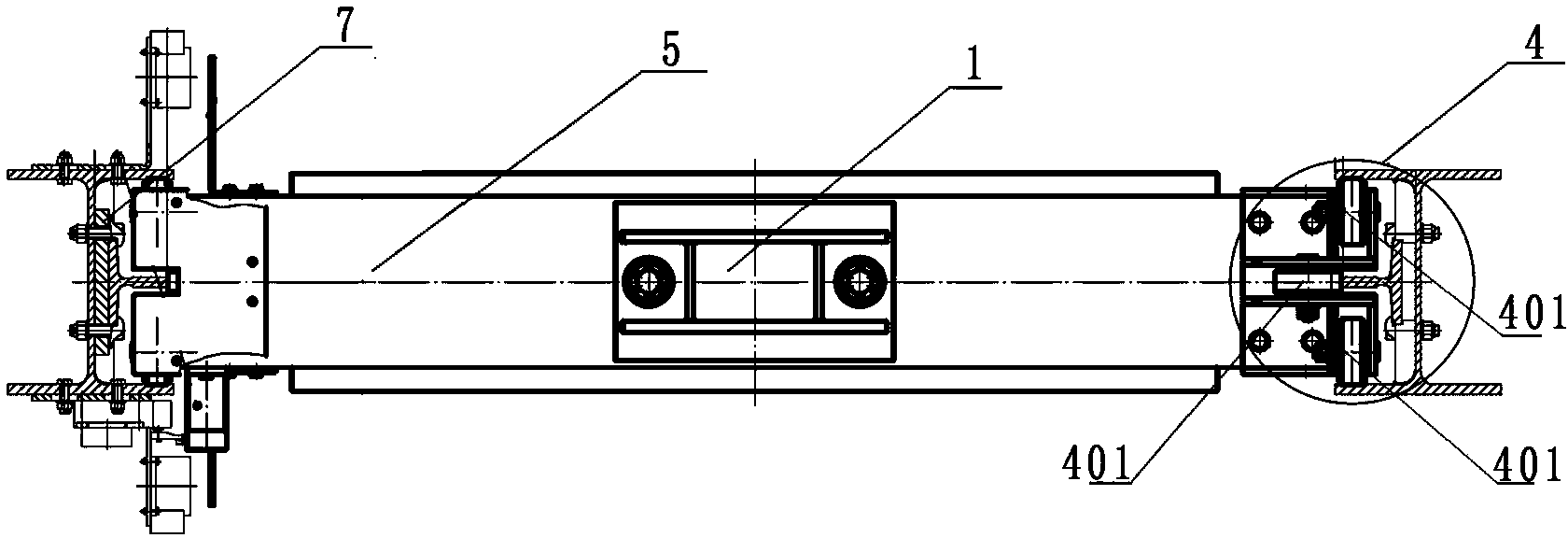

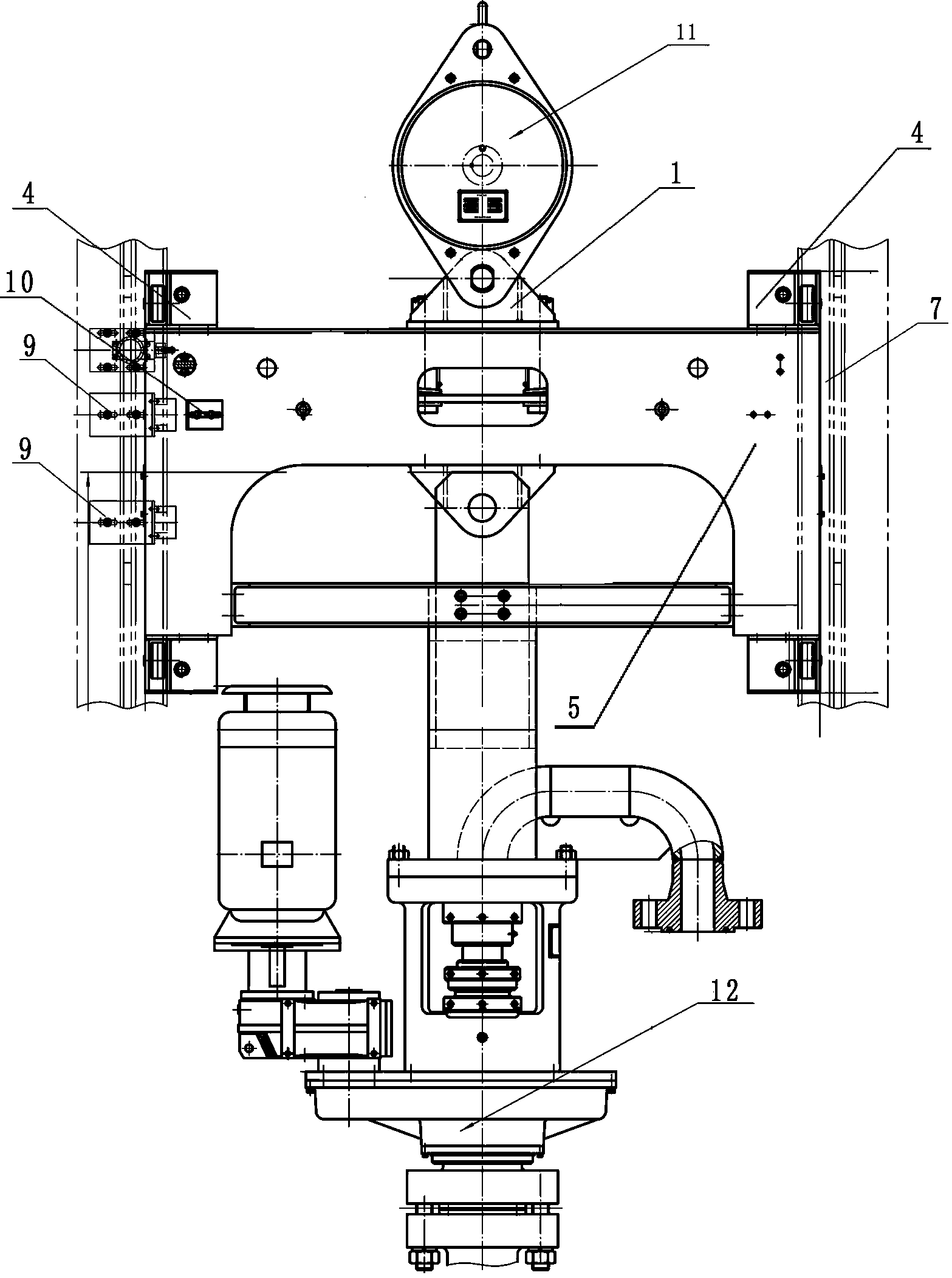

[0023] As shown in the figure, an anti-fall device for a hydraulic decoking system of the present invention, the entire set of anti-fall device actuator is composed of a lifting mechanism 1, a lever mechanism 2, a locking mechanism 3, a guiding mechanism 4, a bracket 5 and electrical accessories , the lifting mechanism 1 is fixedly installed on the top of the bracket 5, and the upper end of the lifting mechanism 1 is fixedly connected with the traveling pulley 11. Adjusting the locking nut of the lifting rod can make the two symmetrically installed locking mechanisms 3 realize synchronous action; the locking mechanisms 3 are respectively Installed on the locking guide rail 7 provided at both ends of the bracket 5, the locking mechanism 3 adopts multi-cylindrical rollers to move, which is sensitive and easy to release; the locking guide rail 7 is also provided with a device for guiding the locking mechanism 3 along the locking guide 7 The guide mechanism 4 that moves up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com