Multi-zone resistance heater

A heater and heating element technology, which is applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating plate heating arrangement, etc., can solve the problem of difficult to isolate the temperature change of the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

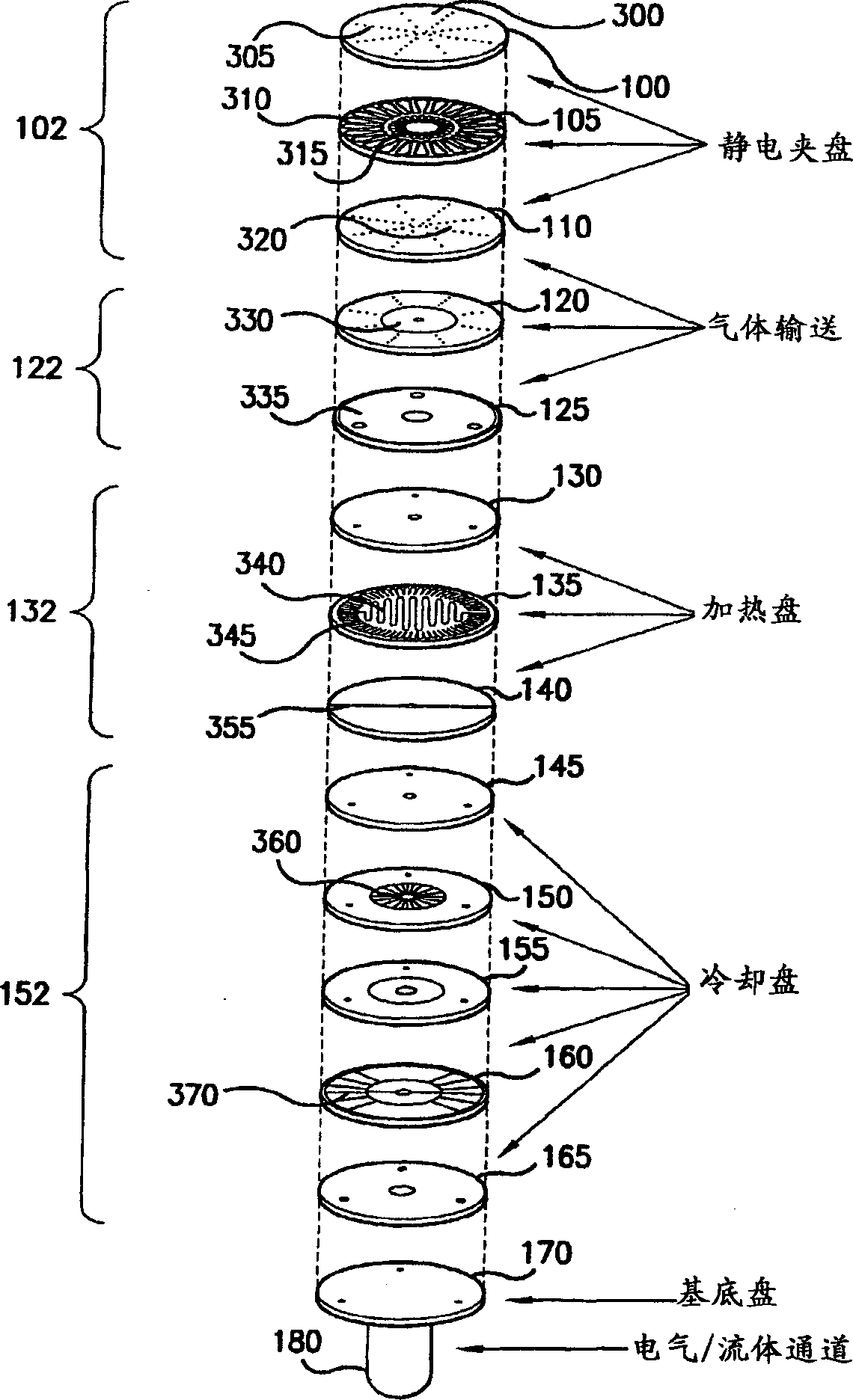

no. 1 example

[0149] Although specific configurations and configurations of the resistive heating elements and cooling sections have been described, the actual configuration of the heating and cooling sections should be determined to match the thermal characteristics of the substrate being heated or cooled. According to a preferred first embodiment of the invention, the substrate to be processed having a certain shape and thickness is uniformly heated in an industrial furnace to the operating temperature to be heated on the chuck. The wafer to be heated is placed on the chuck, and a piece of liquid crystal display (LCD) paper is placed on the heated wafer because the color of the LCD paper changes with temperature. Take pictures of the LCD paper while cooling, observe / record the color of the LCD paper to observe / record the temperature change. The photo of the cooling process shows the opposite of the required heating of the substrate. That is, where heat loss is rapid, additional supplemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com