Automatic locking anti-loosening nut

An anti-loosening nut, automatic locking technology, applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of easily damaged nuts or bolts, reduced connection reliability, low tightening reliability, etc., to prevent loosening. The effect of reliable performance, good tightness and convenient maintenance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

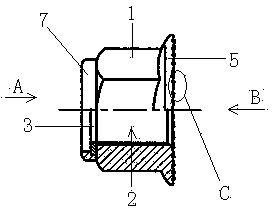

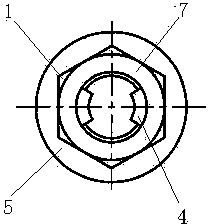

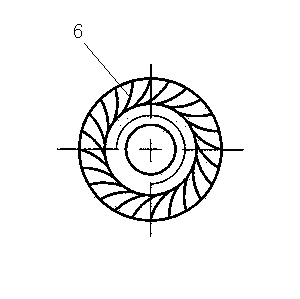

[0021] like figure 1 and figure 2 As shown, the present invention includes a nut body 1 provided with a threaded hole 2, an outwardly extending annular boss 7 is arranged on one end surface of the nut body 1, and an annular elastic locking piece is fixed in the annular hole of the annular boss 7. 3. The central hole of the elastic locking piece 3 is concentric with the threaded hole 2, and the inner diameter of the elastic locking piece 3 is smaller than the inner diameter of the threaded hole.

[0022] A pair of centrally symmetrical protrusions 4 are provided inside the through hole of the locking piece 3 , and the protrusions 4 protrude radially toward the center of the through hole. The number of protruding parts 4 is not limited to two, and may be more than two.

[0023] Relying on the elasticity of the elastic locking piece 3 itself and the protruding part 4, when the bolt is assembled, it is tightly clamped on the side surface of the external thread of the bolt, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com