Method for controlling a clutch connected to an electric machine when a combustion engine starts

A technology of heat engine and control method, which is applied in the directions of electric motor start for engine, arrangement of multiple different prime movers of general power plant, engine start, etc., and can solve problems such as how to control the speed gradient of heat engine without description or suggestion , to optimize vibration and sound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that the drawings are given as examples and not as limitations on the present invention. The drawings are schematic diagrams that help to understand the principles of the present invention, and are not necessarily actual scales. In particular, the dimensions of the various components shown do not represent actual conditions.

[0032] In the following, all drawings shall be combined for reference. When referring to a specific drawing, that drawing and another attached Figure one It is used to identify the designated number reference sign.

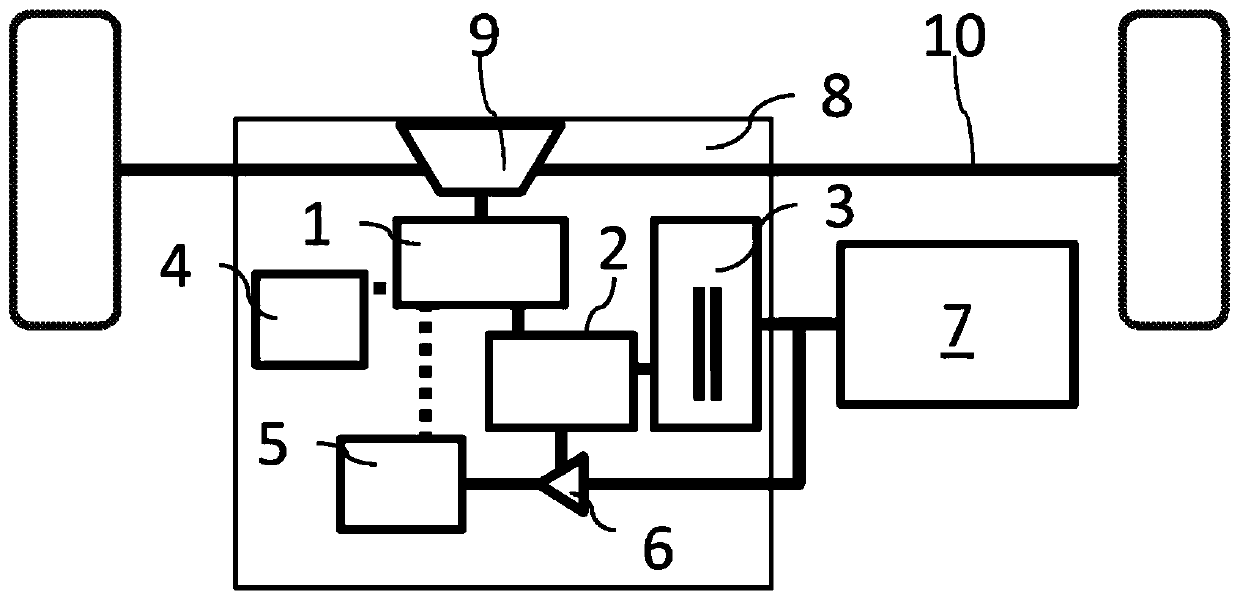

[0033] figure 1 A hybrid traction chain 8 connected to a drive axle 10 is shown, which is equipped with a differential 9. The traction chain 8 is equipped with an electrified gearbox 1, 2, which includes an effective gearbox 1 and a traction motor 2 connected to the gearbox 1. The traction chain 8 also includes a clutch 3 that allows coupling between the traction motor 2 and the heat engine 7.

[0034] The traction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com