Injection production process of fluids produced by supercritical water oxidation

A supercritical water oxidation and fluid technology, applied in the field of energy and environment, can solve problems such as chamber wall damage, boundary layer protection interruption, cooling system failure, etc., achieve broad application prospects, increase oil recovery, and reduce the viscosity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

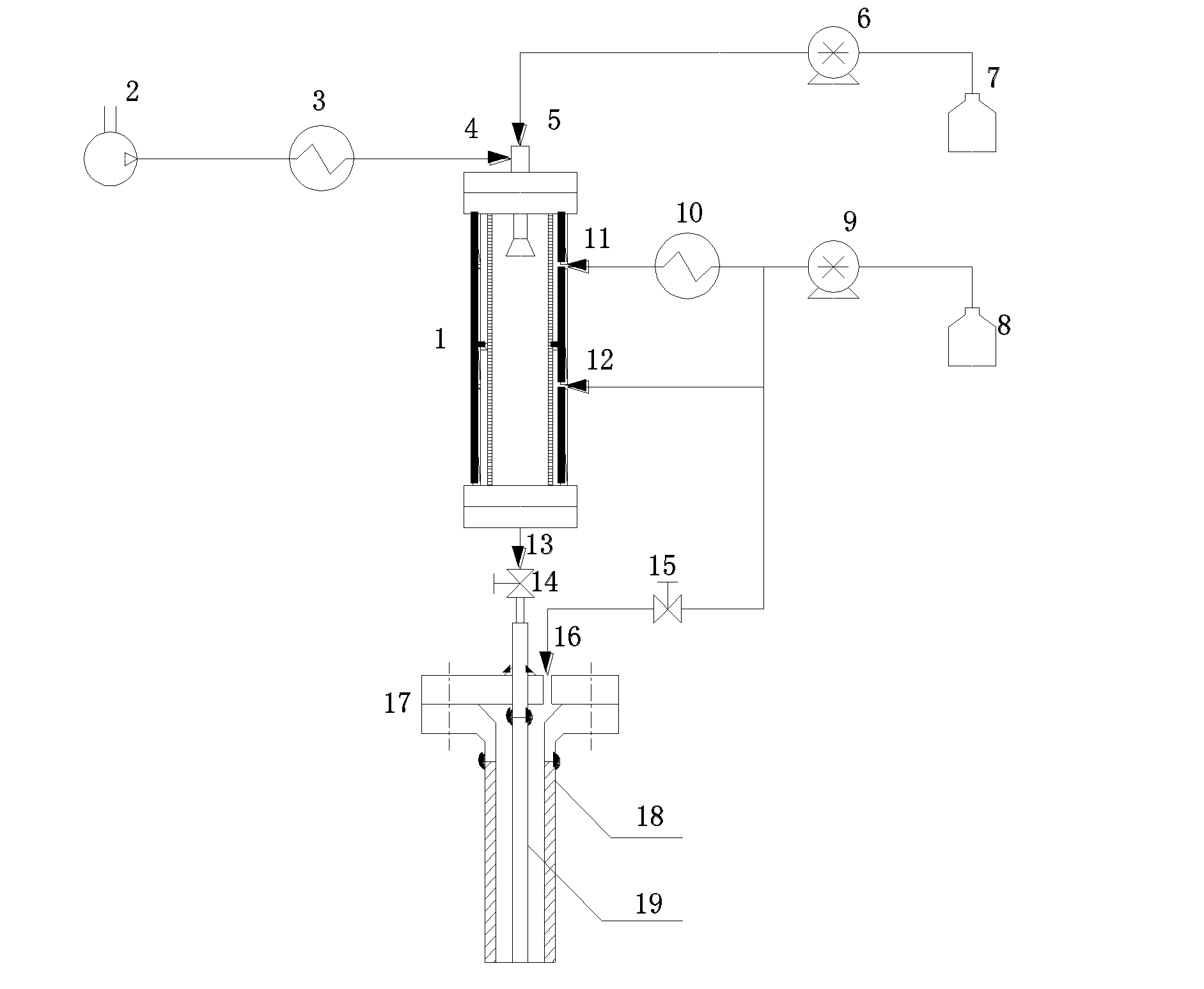

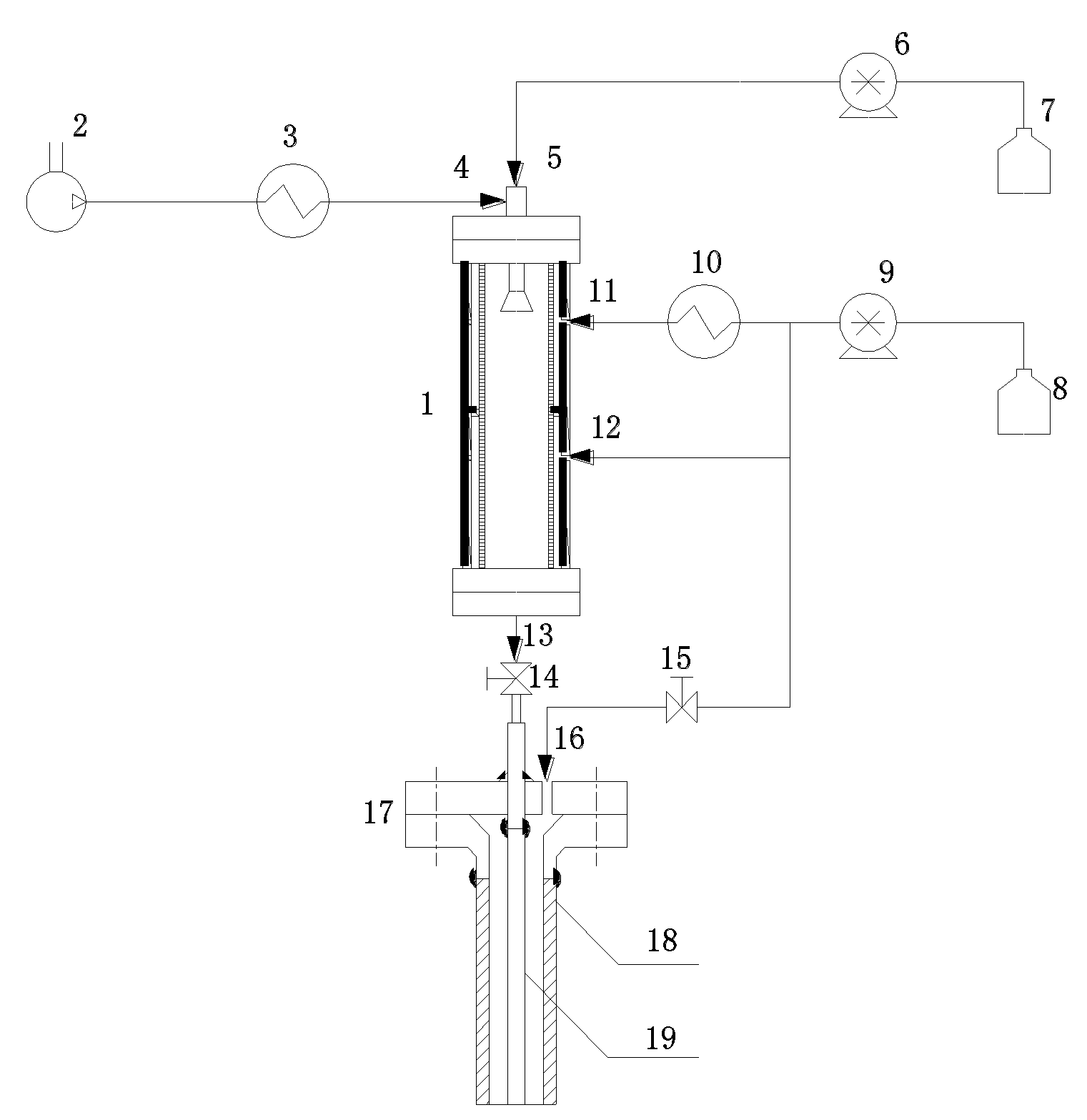

[0021] The crude oil in the fuel tank (7) is boosted to 23MPa by the fuel pump (6), injected into the evaporative wall reactor (1) from the fuel inlet (5) of the evaporative wall reactor, and the air is boosted to 23MPa by the air compressor (2) After preheating to 400℃ by air heater (3), it is injected into the evaporative wall reactor (1) from the air inlet (4) of the evaporative wall reactor, and the evaporated water in the evaporative water tank (8) is passed through the evaporative water pump (9) The pressure is increased to 23MPa and divided into three branches, two of which are injected from the side of the evaporation wall reactor (1). The first branch is preheated to 500°C by the evaporative water heater (10), as the upper branch evaporating water is injected into the evaporation wall reaction (1) from the upper branch evaporating water inlet (11); the second branch is used as the lower The branch evaporating water is injected into the evaporating wall reactor (1) from...

Embodiment 2

[0023] The difference between this embodiment and the first embodiment is that the crude oil is replaced with high-concentration oil production wastewater. While generating multiple thermal fluids, it can also realize the harmless treatment of oil production wastewater, which has a good environmental effect. The rest of the process and implementation Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com