Well cementation cement system for in-situ combustion

A technology of cementing and burning oil layers, which is applied in solid waste management, drilling composition, sustainable waste treatment, etc., can solve the problems of resistance to ultra-high temperature conditions, stability and uniformity of cement stones that are difficult to achieve in burning oil layers in thermal recovery wells. Qualitative damage, shortening the production life of heavy oil thermal recovery wells, etc., to achieve the effects of controllable thickening time, good cementing quality, and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

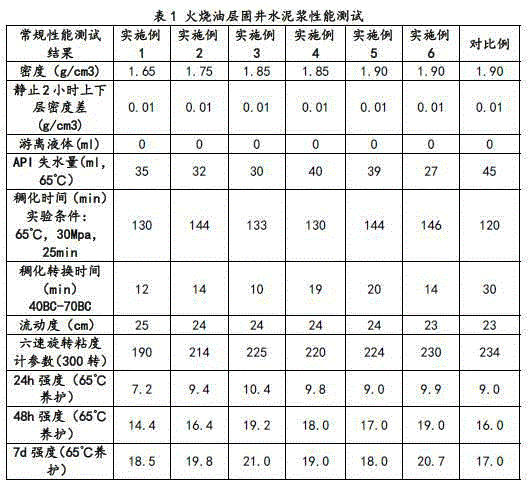

Examples

Embodiment 1

[0028] Cementing cement system for burning oil layers: Weigh each component according to the following weight components: 50 parts of G grade oil well cement; 50 parts of CA50-G6 aluminate cement, 20 parts of fly ash, 20 parts of quartz sand, 14 parts of micro silicon, 1.4 parts of sodium lignosulfonate, 0.6 parts of retarder and 1.6 parts of fluid loss reducer, wherein the retarder is calcium hydrogen phosphate, and the fluid loss reducer is polyvinyl alcohol.

[0029] In this embodiment, the quartz sand is sieved by 0.15 mm, and the sieved quartz sand is selected.

[0030] Cementing cement slurry system for burning oil layers: Add 97 parts of tap water to the above cement system. The cement slurry was prepared according to the oil and gas well cementing cement slurry test standard ISO 10426-2003.

Embodiment 2

[0032] Cementing cement system for burning oil layers: 50 parts of G grade oil well cement, 50 parts of CA50-G6 aluminate cement, 20 parts of fly ash, 20 parts of quartz sand, 14 parts of micro silicon, 1.4 parts of sodium lignosulfonate , 6 parts of iron ore powder, 0.8 parts of retarder and 1.7 parts of fluid loss reducer, wherein the retarder is sodium citrate, and the fluid loss reducer is AM / AA / AMPS copolymer.

[0033] In this embodiment, the quartz sand is sieved by 0.15 mm, and the sieved quartz sand is selected.

[0034] The particle size of the hematite powder is 200 mesh to 500 mesh, and the density is 4.5 g / cm 3 .

[0035] Cementing cement slurry system for burning oil layers: Add 97 parts of tap water to the above cement system. The cement slurry was prepared according to the oil and gas well cementing cement slurry test standard ISO 10426-2003.

Embodiment 3

[0037] Cementing cement system for burning oil layers: 50 parts of G grade oil well cement, 50 parts of CA50-G6 aluminate cement, 20 parts of fly ash, 20 parts of quartz sand, 14 parts of micro silicon, 1.4 parts of sodium lignosulfonate , 12 parts of iron ore powder, 0.9 parts of retarder and 1.8 parts of fluid loss reducer, the retarder is D-sodium gluconate, and the fluid loss reducer is AM / AA / AMPS copolymer.

[0038] In this embodiment, the quartz sand is sieved by 0.15 mm, and the sieved quartz sand is selected.

[0039] The particle size of the hematite powder is 500 mesh to 800 mesh, and the density is 4.8g / cm 3 .

[0040] Cementing cement slurry system for burning oil layers: Add 97 parts of tap water to the above cement system. The cement slurry was prepared according to the oil and gas well cementing cement slurry test standard ISO 10426-2003.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com