Method for increasing oil recovery ratio by utilizing symbiotic reproduction and complex metabolism and microbial preparation

A microbial preparation and recovery factor technology, applied in the field of CR-CM technology, can solve the problems of unstable oil production microbial communities in oil reservoirs, inability to accurately understand reservoir microorganisms, and neglect of multi-compatibility of microorganisms, so as to increase oil recovery. efficiency, prolongation of production time, and the effect of improving reservoir conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

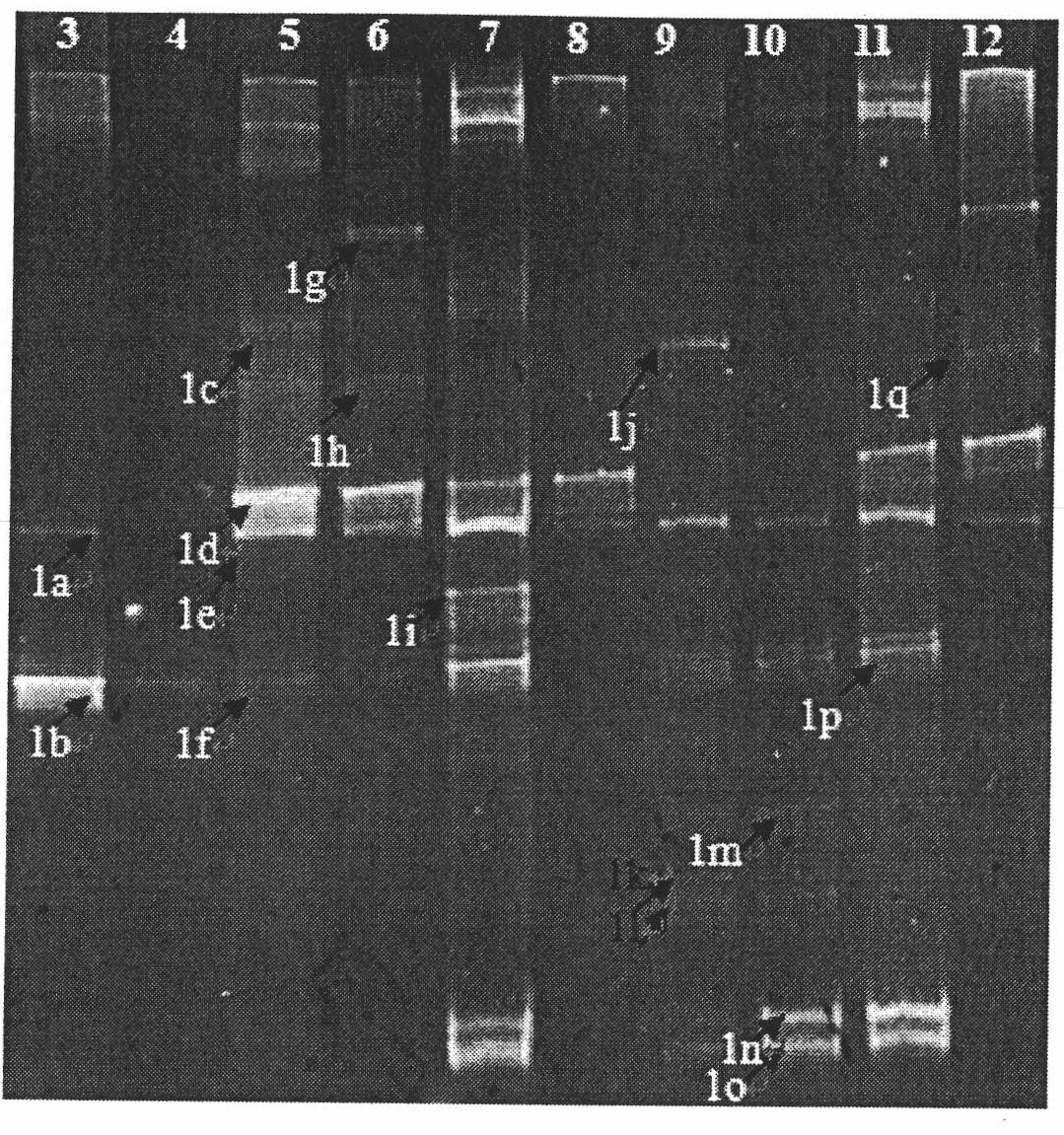

[0037] Example 1 Reservoir Specific Oil Well Selection and Molecular Evaluation System

[0038] Reservoir investigation: investigate the geological conditions of the reservoir, including reservoir temperature, porosity, pressure, permeability, recovery degree, remaining oil distribution, oil product characteristics, formation water salinity, etc. The environment also includes the micro-environment of the micro-environment of the oil reservoir microorganisms. The present invention has no specific limitation on the microbial environment of the oil reservoir, as long as there are microbial flora in the oil reservoir, there is no need to specifically limit what kind of microorganisms it is. The specific applicable reservoir parameters are as follows:

[0039] Temperature3%, water content>10%, permeability>20×10 -3 μm 2 ;

[0040] 1. Extraction of metagenomic DNA from oil reservoir soil or water samples

[0041] Reservoir soil samples were taken from Well Meng 9-11 at a depth o...

Embodiment 2

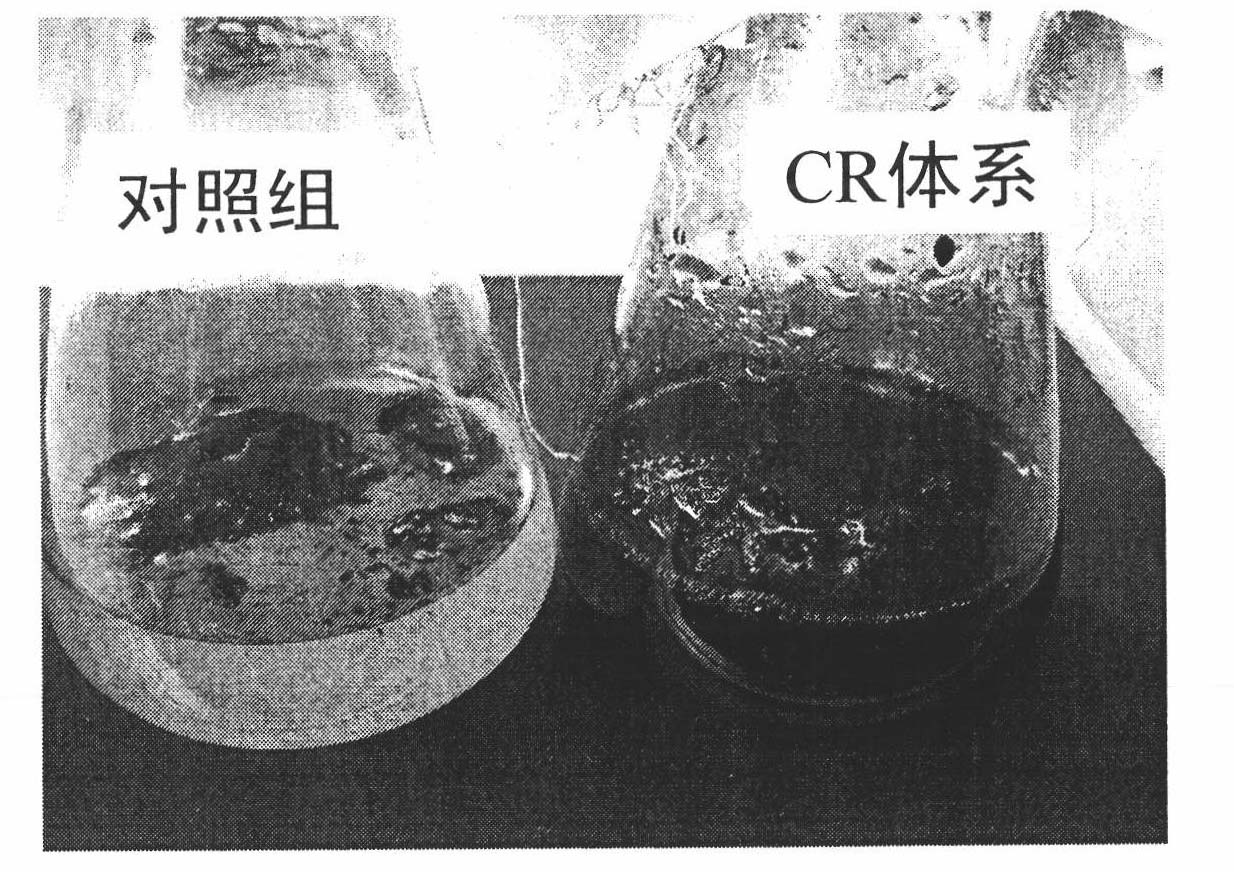

[0050] Example 2 Establishment and effect evaluation of laboratory CR co-metabolism system

[0051] In order to ensure the effect of the CR system field experiment, we conducted indoor evaluation tests on the CR system of each well before construction, mainly including emulsification viscosity reduction test, surface tension and acidity change test. Utilize Rhodococcus erythropo LY-LH-11a described in the present invention, preservation number is: CGMCCNo.3510 and stenotrophmonas (Stenotrophmonas maltophilia LY-LH-11b), preservation number is: CGMCC No. 3509 composite microbial agent was tested, and the numbering system was CR-J3 system.

[0052] 1. Emulsification viscosity reduction test

[0053] After sterilizing the culture medium, put them into 500mL experimental bottles, each containing 100mL, and add 80g of sterilized crude oil. Keep three blank parallel samples, and insert two strains (Rhodococcus CGMCC No.3510 and Stenotrophomonas CGMCC No.3509. 5% inoculum) into the...

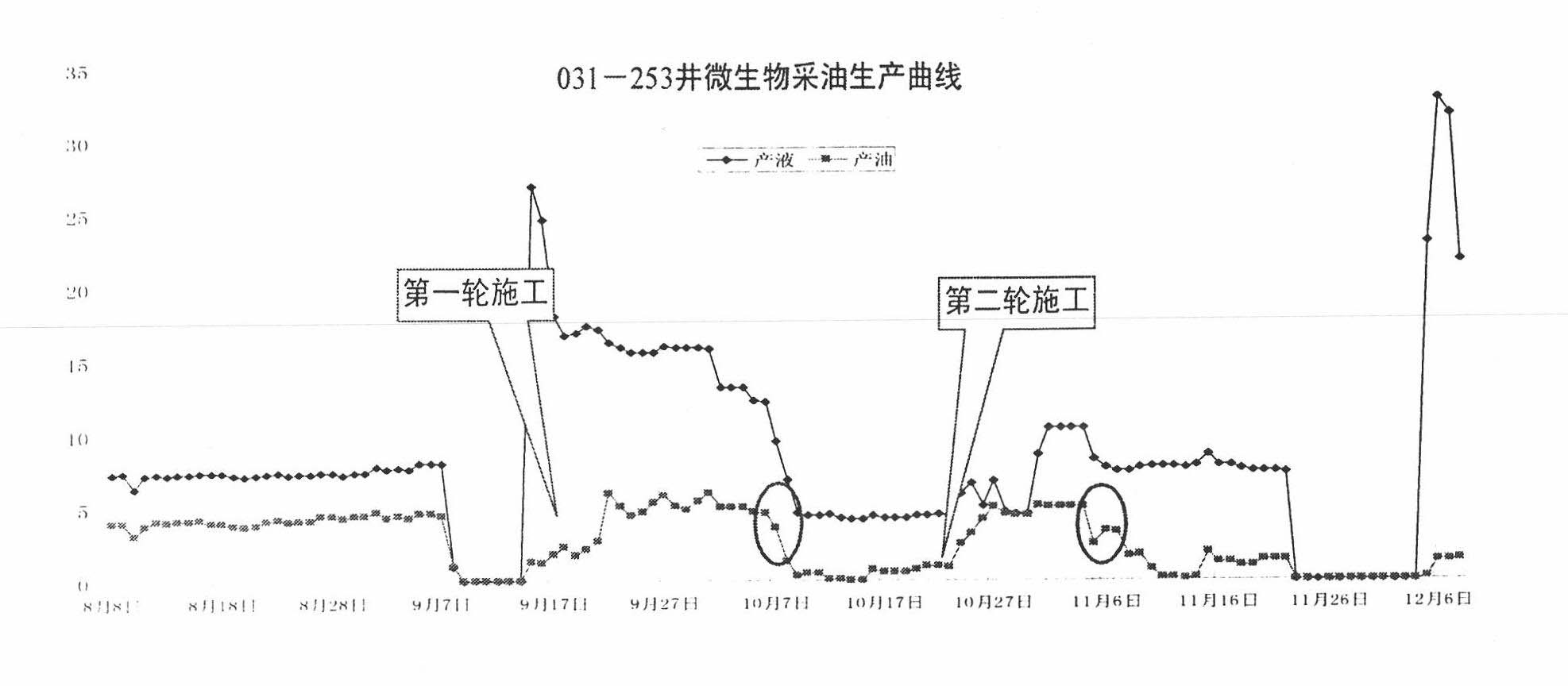

Embodiment 3

[0068] Embodiment 3 activator selection and evaluation

[0069] 1. Reservoir formation water bacteria activation experiment

[0070] The present invention selects the activator as an emulsification activator and a gas production activator, and the formula of the emulsification activator is: 3wt‰molasses, 50wt‰C 12 or C 16 , dipotassium hydrogen phosphate 1wt‰, ammonium nitrate 4wt‰; the laboratory number of the emulsification activator of the present invention is CY5.

[0071] The gas production activator formula: molasses 8wt‰, bran 2wt‰, dipotassium hydrogen phosphate 1.5wt‰, ammonium nitrate 0.5wt‰. The laboratory number of the gas production activator of the present invention is CY9.

[0072] After the activator treatment, the total biomass after activation increased by 4 to 5 orders of magnitude, as shown in Table 3. At the same time, the functional bacteria were activated and the harmful bacteria were effectively inhibited, achieving the purpose of selective activatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com