Nano composite core-shell particle oil-displacing agent and preparation method and application thereof

A nano-composite, oil-displacing agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large amount of surfactant used, increased oil recovery cost, large adsorption loss, etc., to improve temperature and resistance Salinity, reduce the cost of oil displacement, and reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

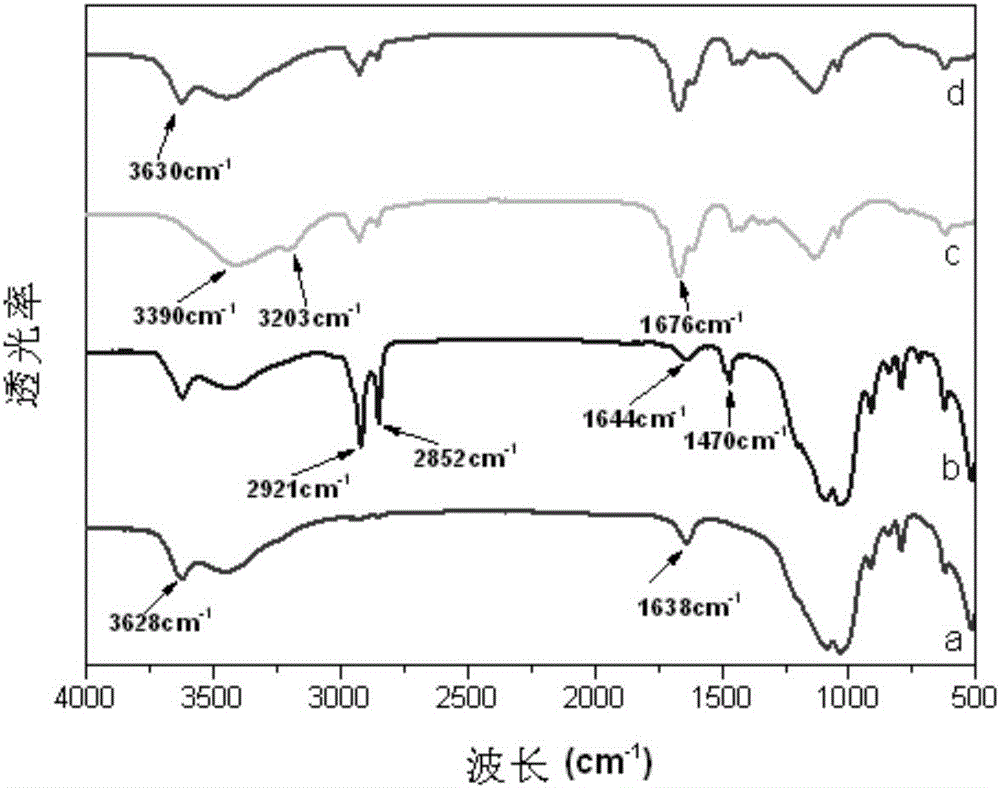

[0043] Example 1 Preparation of layered silicate loaded with oil displacement surfactant

[0044] a. Mix montmorillonite and water in a reaction kettle at a ratio of 1:20 by mass, and stir at room temperature for 30 minutes to form a swelling system;

[0045] b. The temperature of the above-mentioned swelling system was raised to 80° C., and 20% cetyltrimethylammonium bromide was added based on the mass of montmorillonite, the frequency of the mixer was set to 30 Hz, and the stirring reaction was carried out for 6 hours;

[0046] c. based on the quality of montmorillonite, add 20% 3-sulfopropyl hexadecyl dimethyl betaine (industrial product) to the reaction system obtained above, continue to react for 4h, and obtain the oil displacement surfactant of load layered silicate slurry;

[0047] d. Suction filtration, drying, grinding, and sieving of the above slurry to obtain layered silicate powder loaded with oil displacement surfactant, which is ready for use.

[0048] The prep...

Embodiment 2

[0053] Example 2 Preparation of Layered Silicate Loaded Oil Displacement Surfactant

[0054] a. Mix montmorillonite and water in a reaction kettle at a ratio of 1:20 by mass, and stir at room temperature for 30 minutes to form a swelling system;

[0055] b. The temperature of the above swelling system was raised to 80°C, 20% cetyltrimethylammonium chloride was added based on the mass of montmorillonite, the frequency of the mixer was set to 30Hz, and the stirring reaction was carried out for 6h;

[0056] c. based on the quality of montmorillonite, add 20% 3-sulfopropyl hexadecyl dimethyl betaine (industrial product) to the reaction system obtained above, continue to react for 4h, and obtain the oil displacement surfactant of load layered silicate slurry;

[0057] d. Suction filtration, drying, grinding, and sieving of the above slurry to obtain layered silicate powder loaded with oil displacement surfactant, which is ready for use.

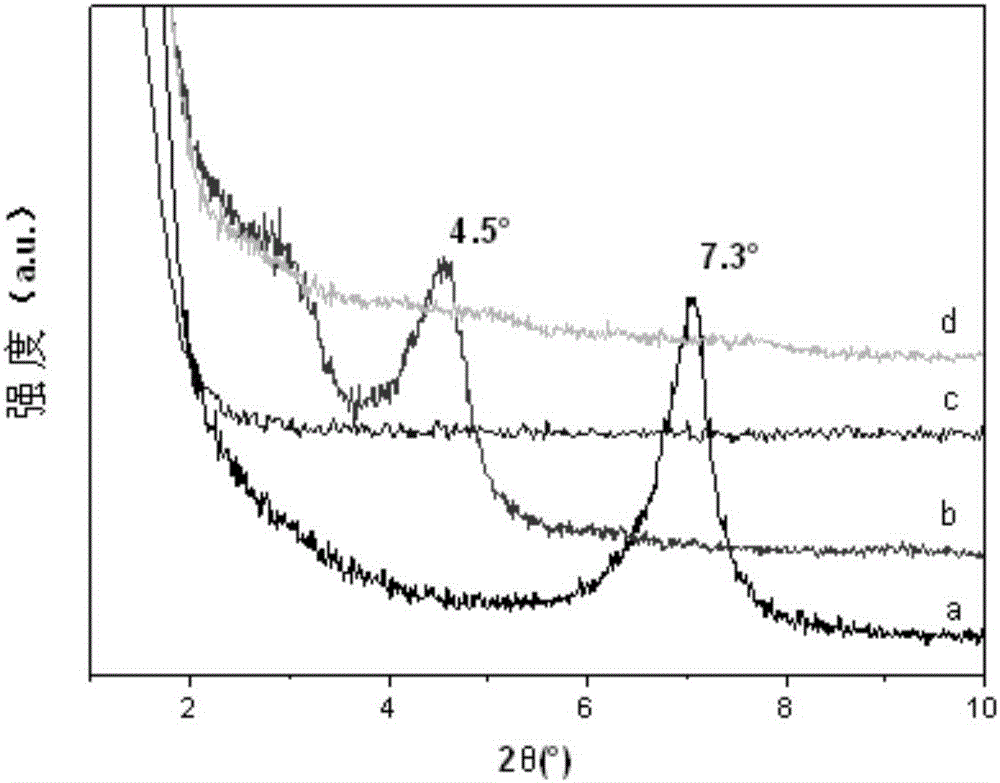

[0058] After detection, the interlayer sp...

Embodiment 3

[0059] Example 3 Preparation of Layered Silicate Loaded Oil Displacement Surfactant

[0060] a. Mix kaolin and water in a reaction kettle at a ratio of 1:20 by mass, and stir at room temperature for 30 minutes to form a swelling system;

[0061] b. Heat up the swelling system to 80°C, add 20% cetyltrimethylammonium bromide based on the mass of kaolin, set the mixer frequency to 30Hz, and stir for 8 hours;

[0062] c. Based on the quality of kaolin, add 20% 3-sulfopropyl hexadecyl dimethyl betaine (industrial product) to the reaction system obtained above, and continue to react for 6h to obtain a layered surface active agent loaded with oil displacement Silicate slurry;

[0063] d. Suction filtration, drying, grinding, and sieving of the above slurry to obtain layered silicate powder loaded with oil displacement surfactant, which is ready for use.

[0064] After detection, the interlayer spacing of the layered silicate loaded with the oil displacement surfactant is 2.17nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com