Preparation method of partially hydrolyzed polyacrylamide with improved temperature and salt resisting performances

A polyacrylamide, temperature-resistant and salt-resistant technology, which is applied in the field of preparation of partially hydrolyzed polyacrylamide, can solve the problems of inability to produce high-performance products, high production process costs, and low production efficiency, so as to reduce investment in production equipment, The effect of reducing equipment investment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

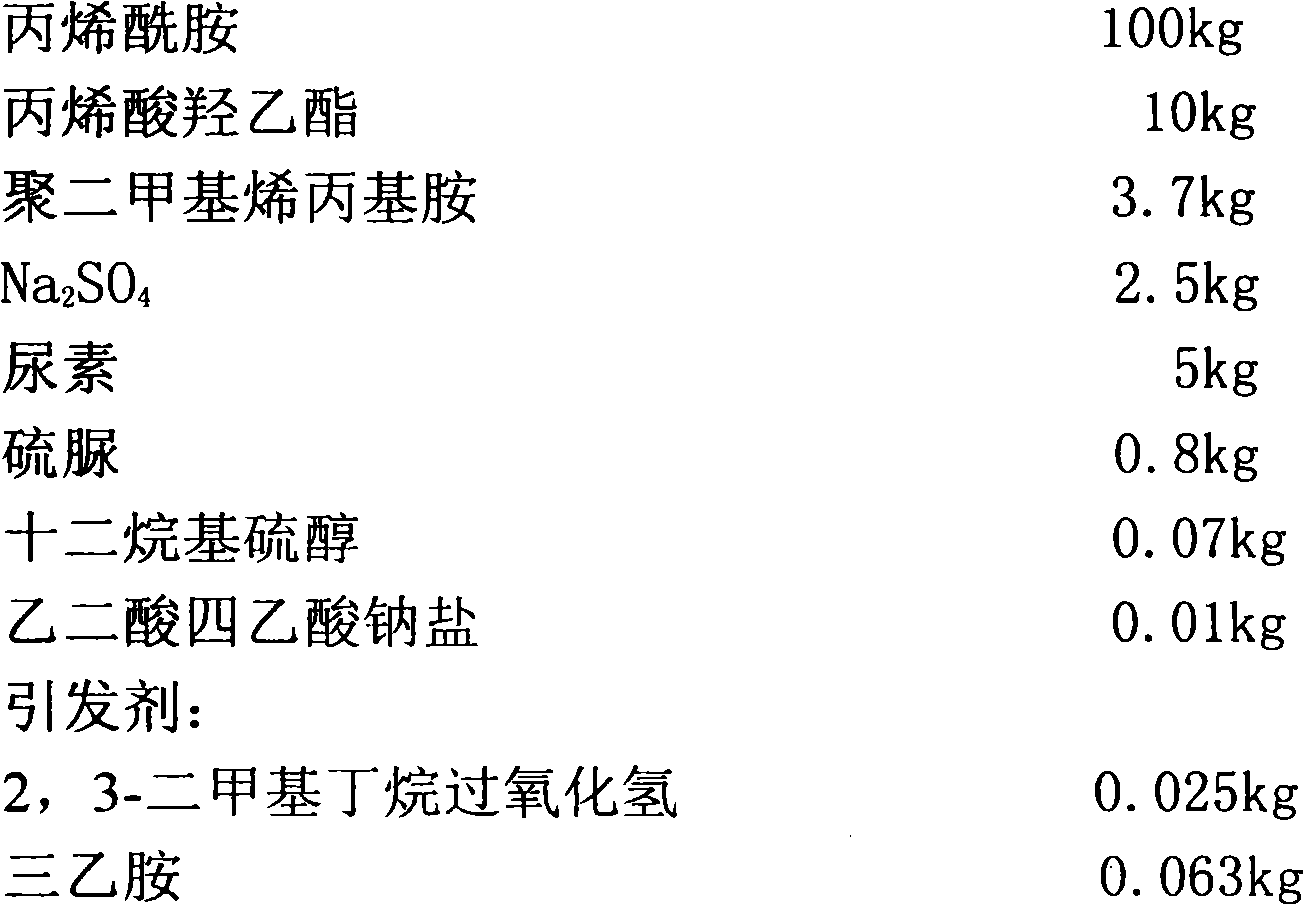

[0048] Weigh each component according to the following formula:

[0049]

[0050] Dissolve each of the above-mentioned initiators in distilled water in a 1-liter beaker and store away from light; dissolve the remaining components in the batching kettle, add distilled water to 500kg to obtain a polymerization solution, and input the polymerization solution into the polymerization kettle, and pour it into the polymerization solution Introduce high-purity nitrogen to drive away oxygen, and at the same time cool down the temperature of the polymerization solution. When the temperature of the polymerization solution drops to 8°C, first add the prepared triethylamine aqueous solution into the polymerization kettle, and then add the prepared 2,3-dimethyl Butane hydrogen peroxide aqueous solution is added in the polymerization kettle, continue to feed high-purity nitrogen after adding, stop passing high-purity nitrogen after 10 minutes, seal the polymerization kettle, make the polym...

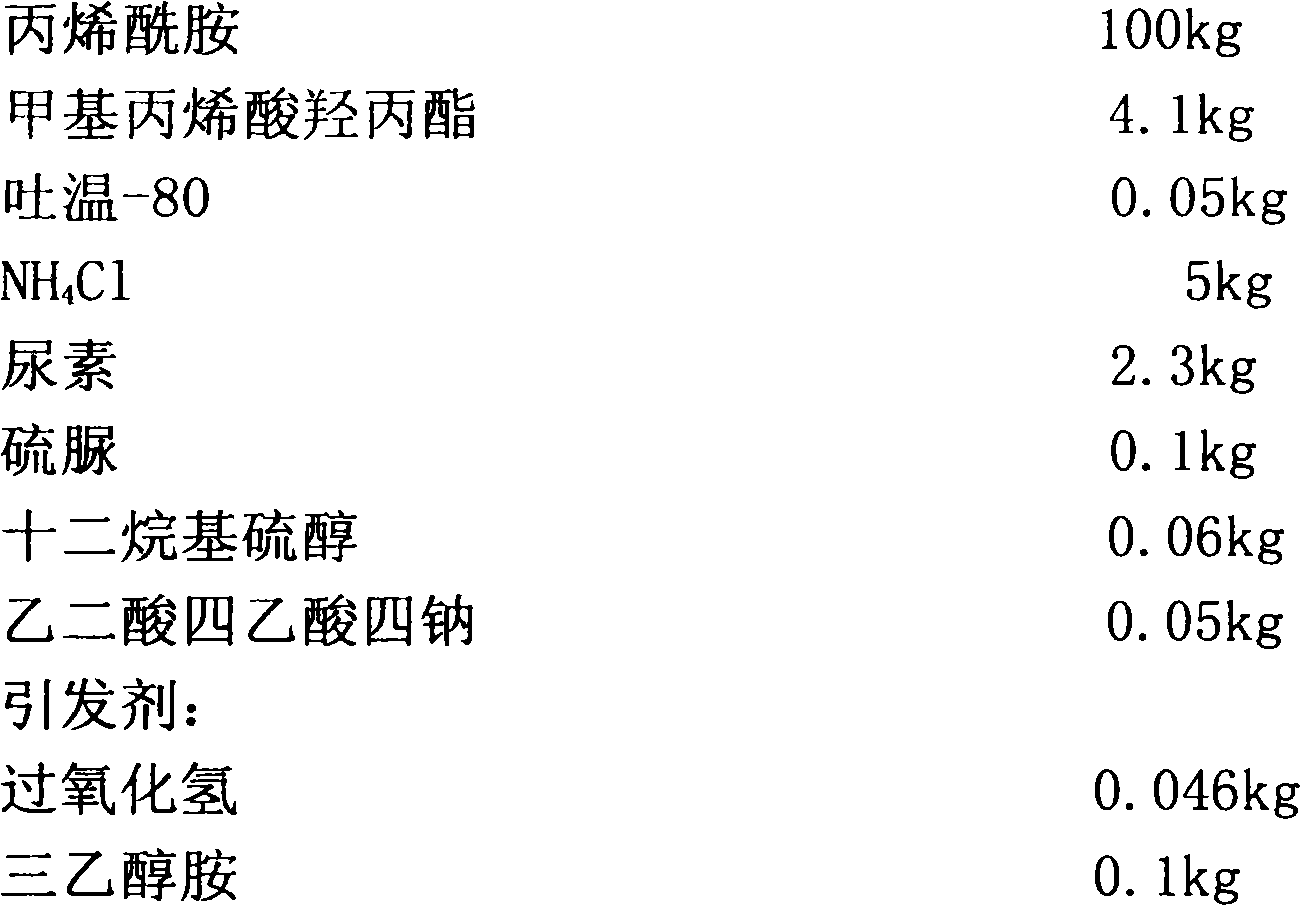

Embodiment 2

[0062]

[0063] Weigh each component according to the above formula, control the initial reaction temperature at 3°C, and other operating steps are the same as in Example 1, except that the amount of NaOH added during hydrolysis is 15 kg, and the molecular weight of the obtained polymer is 29 million. The viscosity is 15%, the viscosity is 31.9cp at 25°C, and 16.7cp at 85°C.

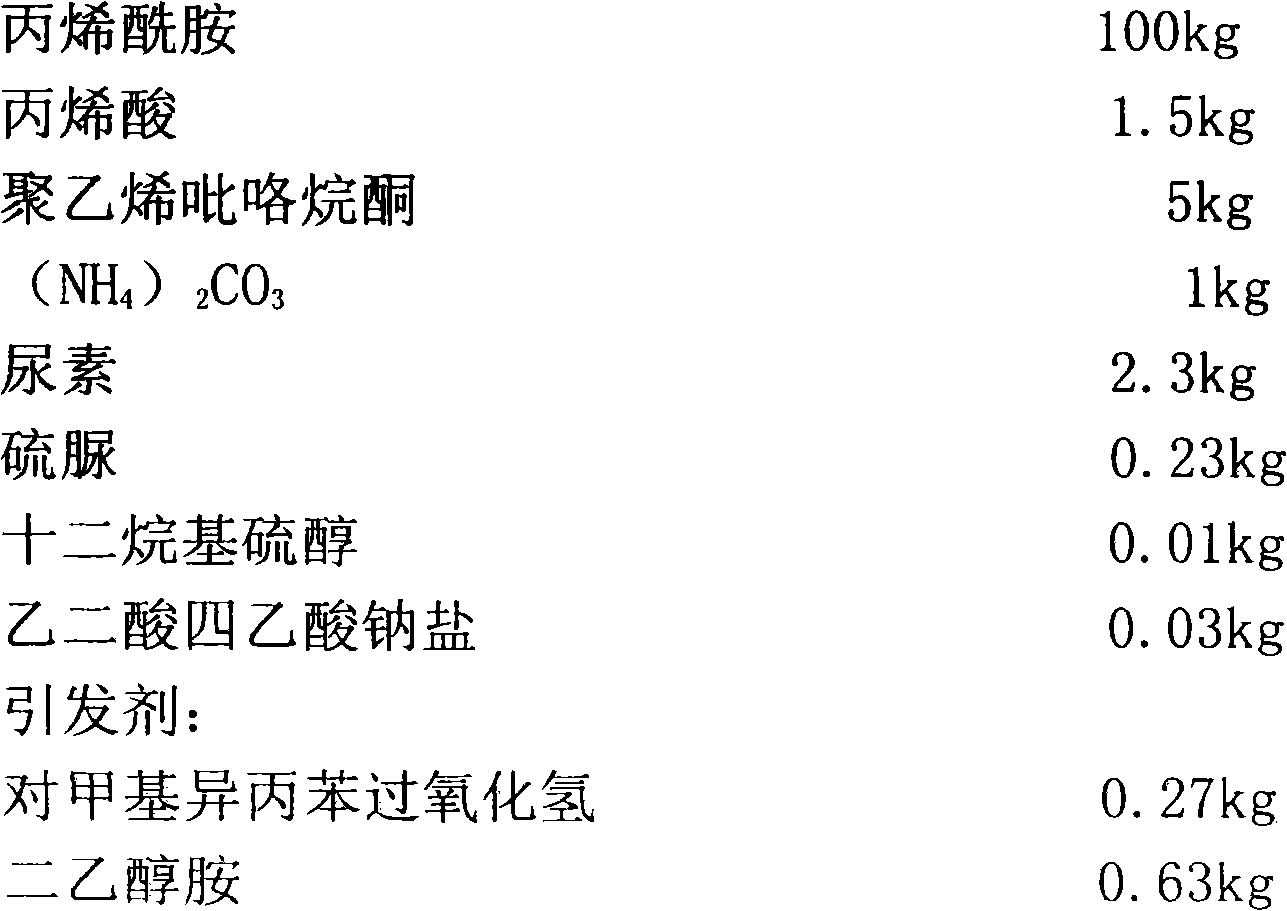

Embodiment 3

[0065]

[0066] Each component was weighed according to the above formula, and the initial reaction temperature was controlled at 0°C. Other operating steps were the same as in Example 1, except that the amount of NaOH added during hydrolysis was 30 kg, and the molecular weight of the obtained polymer was 29 million. The viscosity is 30%, the viscosity is 33.2cp at 25°C, and 17.5cp at 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com