Method for mining tight oil reservoir by nanometer fluid

A nano-fluid, dense technology, applied in the fields of fluid extraction, chemical instruments and methods, and earth-moving drilling, can solve the problems of high risk, poor water-flooding development effect, violent flooding, etc., and achieve the effect of improving oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

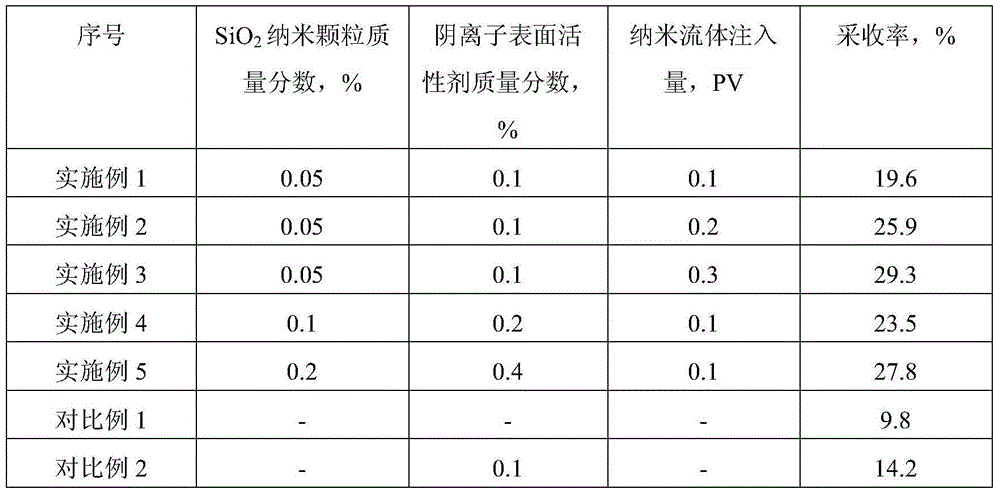

Embodiment 1

[0026] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated tight oil reservoir; inject a nanofluid slug into the simulated tight oil reservoir for oil displacement, and then perform water flooding.

[0027] The inner diameter of the tight oil core is 2.54 cm, the length is 5 cm, and the permeability is 0.08 mD. SiO with a particle size of 10nm-30nm in the nanofluid 2 The mass fraction of nanoparticles is 0.05%, the mass fraction of anionic surfactant is 0.1%, the balance is water, the anionic surfactant is sodium petroleum sulfonate, the injection volume of nanofluid is 0.1PV, and the injection speed of nanofluid and water is equal to It is 1.0m / d.

Embodiment 2

[0029] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated tight oil reservoir; inject a nanofluid slug into the simulated tight oil reservoir for oil displacement, and then perform water injection and injection Nanofluid Alternate Oil Displacement.

[0030] The inner diameter of the tight oil core is 2.54 cm, the length is 5 cm, and the permeability is 0.08 mD. SiO with a particle size of 10nm-30nm in the nanofluid 2 The mass fraction of nanoparticles is 0.05%, the mass fraction of anionic surfactant is 0.1%, and the balance is water. The anionic surfactant is sodium petroleum sulfonate, and the injection volume of nanofluid is 0.2PV. The volume ratio of water and nanofluid is 20:1 when water injection and nanofluid are injected alternately for oil displacement.

Embodiment 3

[0032] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated tight oil reservoir; inject a nanofluid slug into the simulated tight oil reservoir for oil displacement, and then perform water flooding.

[0033] The inner diameter of the tight oil core is 2.54 cm, the length is 5 cm, and the permeability is 0.08 mD. SiO with a particle size of 10nm-30nm in the nanofluid 2 The mass fraction of nanoparticles is 0.05%, the mass fraction of anionic surfactant is 0.1%, and the balance is water. The anionic surfactant is sodium petroleum sulfonate, and the injection volume of nanofluid is 0.3PV. It is 1.2m / d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com