CO2 drive oil-gas-water separate well injecting oil reservoir mixing drive development method

An oil-gas-water mixed flooding technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as low recovery, corrosion, poor formation capacity maintenance, etc., to expand the swept volume, apply The effect of broad prospects and good guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

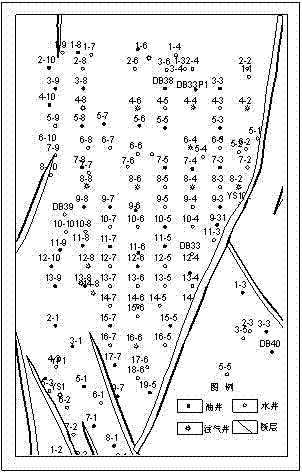

[0020] The following is combined with the accompanying drawings to illustrate the CO injection in an oil field 2 The scheme in oil flooding reservoir engineering is taken as an example to illustrate the implementation process and related effects of the present invention.

[0021] Step 1: According to the geological research data of the oilfield, monitoring data and production dynamic data of oil and water wells, determine that the production well pattern of the oil reservoir is a column well pattern, the well spacing is 500m*180m, and the development strata are Qing 1 and Qing 2 V .

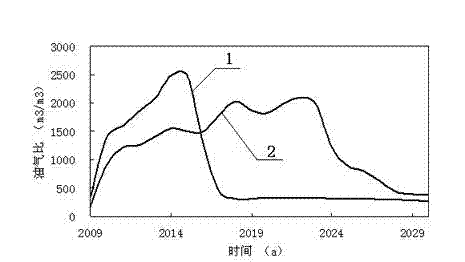

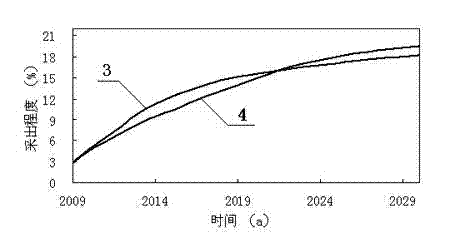

[0022] The second step: on the basis of the gas drive in the whole area, use the numerical simulation calculation of the whole process to carry out the simulation calculation. According to the calculation results, the gas breakthrough time and gas channeling time of the production wells were counted; and the production wells were further sorted according to the time when the oil-gas ratio reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com