Method for relieving water blocking at high temperature in oil and gas exploitation process

A medium-high temperature technology for oil and gas production, applied in earthwork drilling, isolation devices, boreholes/well components, etc., can solve problems such as difficulty in installing high-power microwaves and high power requirements, and improve gas phase permeability and cost Low, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

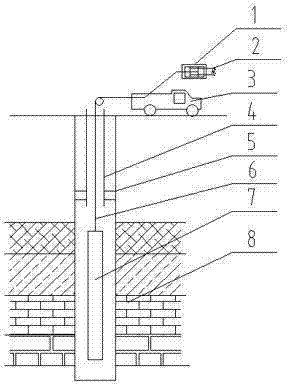

[0027] see figure 1 .

[0028] The steel wire armored high-voltage cable 6 is connected to the electric heating rod 7, and the steel wire armored high-voltage cable 6 is lowered into the oil pipe 4 by using the step-up transformer 1 on the ground of the well site, the ground mains power supply 2 and the winch 3, and the oil pipe 4 has a casing outside 5. The electric heating rod 7 is then lowered to the corresponding depth of the reservoir section 8 .

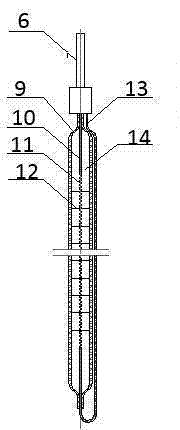

[0029] see figure 2 .

[0030] The steel wire armored high-voltage cable 6 is connected to the electric heating rod. The electric heating rod has a power supply electrode 10 and a power supply circuit electrode 13. There are tungsten wire 11, tungsten wire support bracket 12, and hydrogen bromide gas 14 in the quartz glass cover 9.

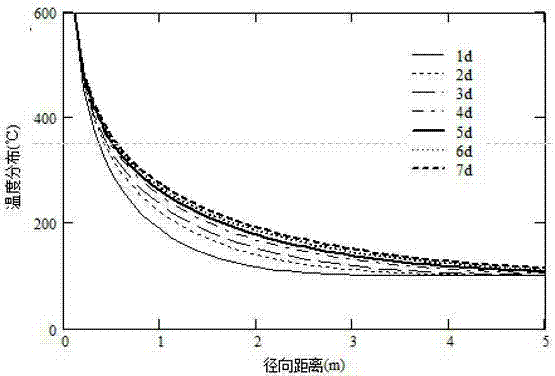

[0031] see image 3 .

[0032] After the electric heating rod connected with the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fever temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com