Method for removing sandstone condensate gas reservoir water lock through nitrogen injection

A technology for condensate gas reservoirs and nitrogen gas, which is applied in earth-moving drilling, production of fluids, wellbore/well components, etc., which can solve the problems of lack of operability, poor effect, mechanism, injection volume, boring time, and poor opening method. issues of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

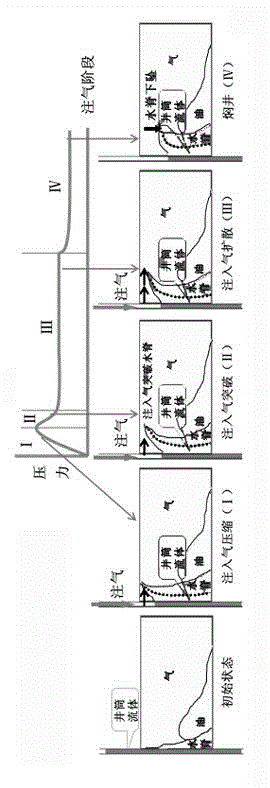

[0014] Example: such as figure 1 As shown, in the initial state, after water breakthrough in the condensate gas well, the intruded water body forms a water ridge around the well, causing water lock near the wellbore, and the gas phase cannot seep into the wellbore. The method for releasing the water lock of the sandstone condensate gas reservoir by injecting nitrogen gas of the present application comprises the following steps:

[0015] (1) Initial stage of nitrogen injection ( figure 1 Medium injection gas compression I): Nitrogen gas gradually compresses the wellbore fluid and the water ridge near the wellbore, and displaces it around the wellbore, and the gas injection pressure gradually rises, which is affected by the effect of gas overburden, and because the density of nitrogen is lower than that of underground air, so Injected nitrogen mainly enters along the top tongue of the reservoir;

[0016] (2) Nitrogen injection breakthrough period ( figure 1 Medium injection g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com