Preparation method of BiOBr/ZnO nano photocatalyst powder

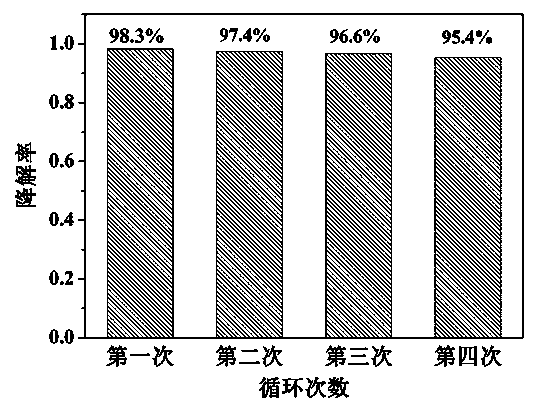

A technology of nano-photocatalyst and photocatalytic activity, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of narrow spectral response range and low photon quantum efficiency, and achieve high reuse rate , The preparation process is simple, and it is convenient for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

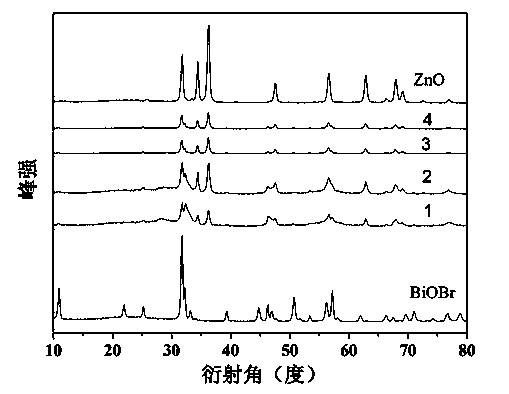

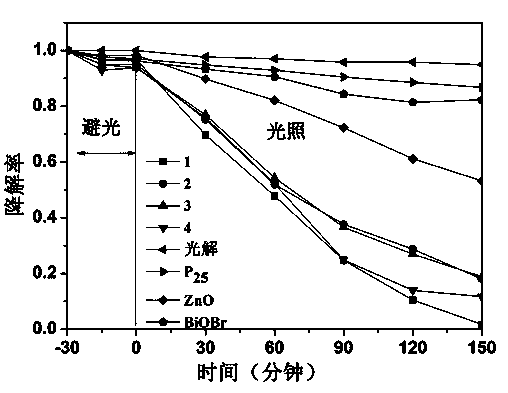

[0021] Add CTAB, sodium bromide at a molar ratio of 0.25 and zinc acetate dihydrate to an ethanol solvent with a Br / Zn molar ratio of 0.1, and stir at room temperature for 0.5 h to form a zinc precursor with a concentration of 0.03 mol / L, and add Bi( NO 3 ) 3 ·5H 2 O, wherein the Bi / Zn molar ratio is 0.8, continue to stir to obtain a milky white turbid liquid, transfer the formed turbid liquid into a Teflon high-pressure reactor, and perform a solvothermal reaction at a temperature of 160 °C for 19 h, and wash the obtained precipitate with distilled water and ethanol After washing and drying, the BiOBr / ZnO nanometer photocatalyst powder is obtained.

Embodiment approach 2

[0023] Add CTAB, potassium bromide and zinc nitrate hexahydrate at a molar ratio of 1 and zinc nitrate hexahydrate to an ethanol solvent with a molar ratio of Br / Zn of 1.5, stir at room temperature for 3 h to form a zinc precursor with a concentration of 0.1 mol / L, and add Bi(NO3 )3·5H2O, wherein the Bi / Zn molar ratio is 0.25, continue to stir to obtain a milky white cloudy liquid, transfer the formed cloudy liquid into a Teflon high-pressure reactor, and conduct a solvothermal reaction at a temperature of 100 °C for 6 h, and use Washing with distilled water and ethanol, and drying to obtain BiOBr / ZnO, nanometer photocatalyst powder.

Embodiment approach 3

[0025] Add CTAB, ammonium bromide at a molar ratio of 2 and zinc nitrate hexahydrate to an ethanol solvent with a Br / Zn molar ratio of 4, stir at room temperature for 5 h to form a zinc precursor with a concentration of 0.3 mol / L, and add Bi (NO 3 ) 3 ·5H 2 O, continue to stir to obtain a milky white turbid liquid, transfer the formed turbid liquid into a Teflon high-pressure reactor, and conduct a solvothermal reaction at a temperature of 140 °C for 15 h, wash the obtained precipitate with distilled water and ethanol, and dry it to obtain BiOBr / ZnO rice photocatalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com