Method for preparing sheet-shaped bismuth oxyiodide (BiOI) nano-film electrode

A bismuth iodide and nano-film technology is applied in the field of preparation of sheet-like bismuth iodide nano-film electrodes, which can solve the problems of lowering battery efficiency, affecting performance, increasing cost and the like, and achieving uniform distribution, stable product quality, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

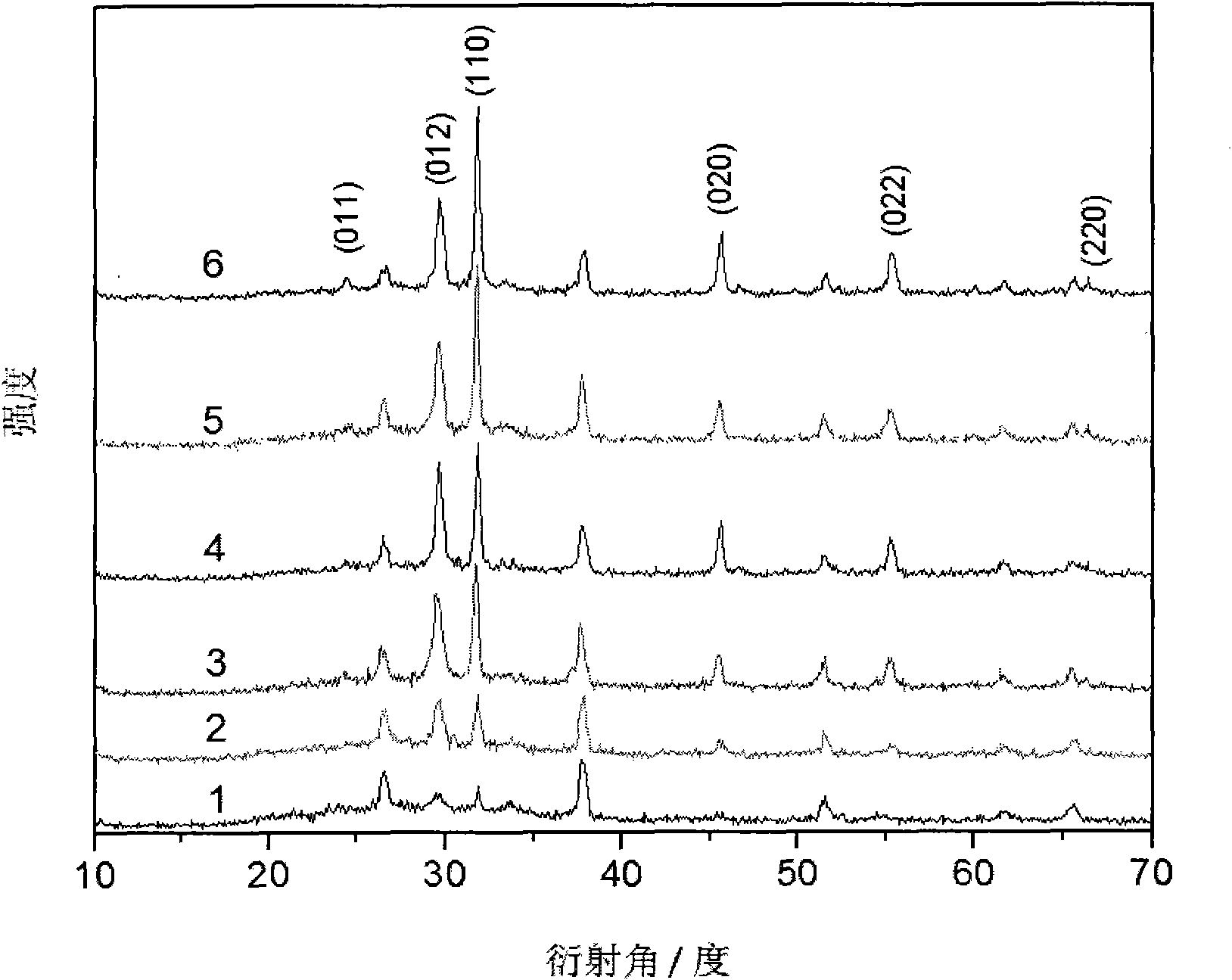

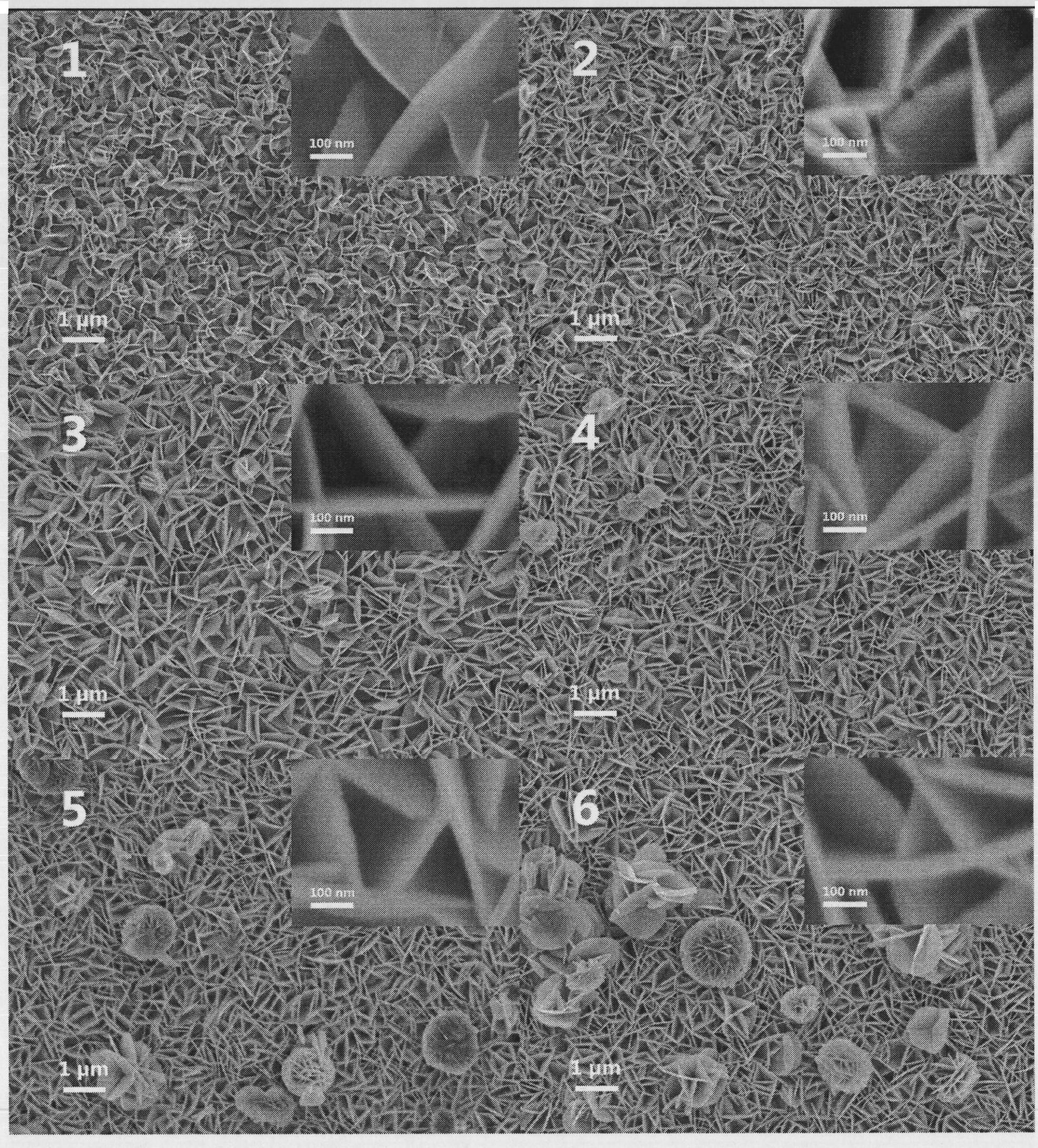

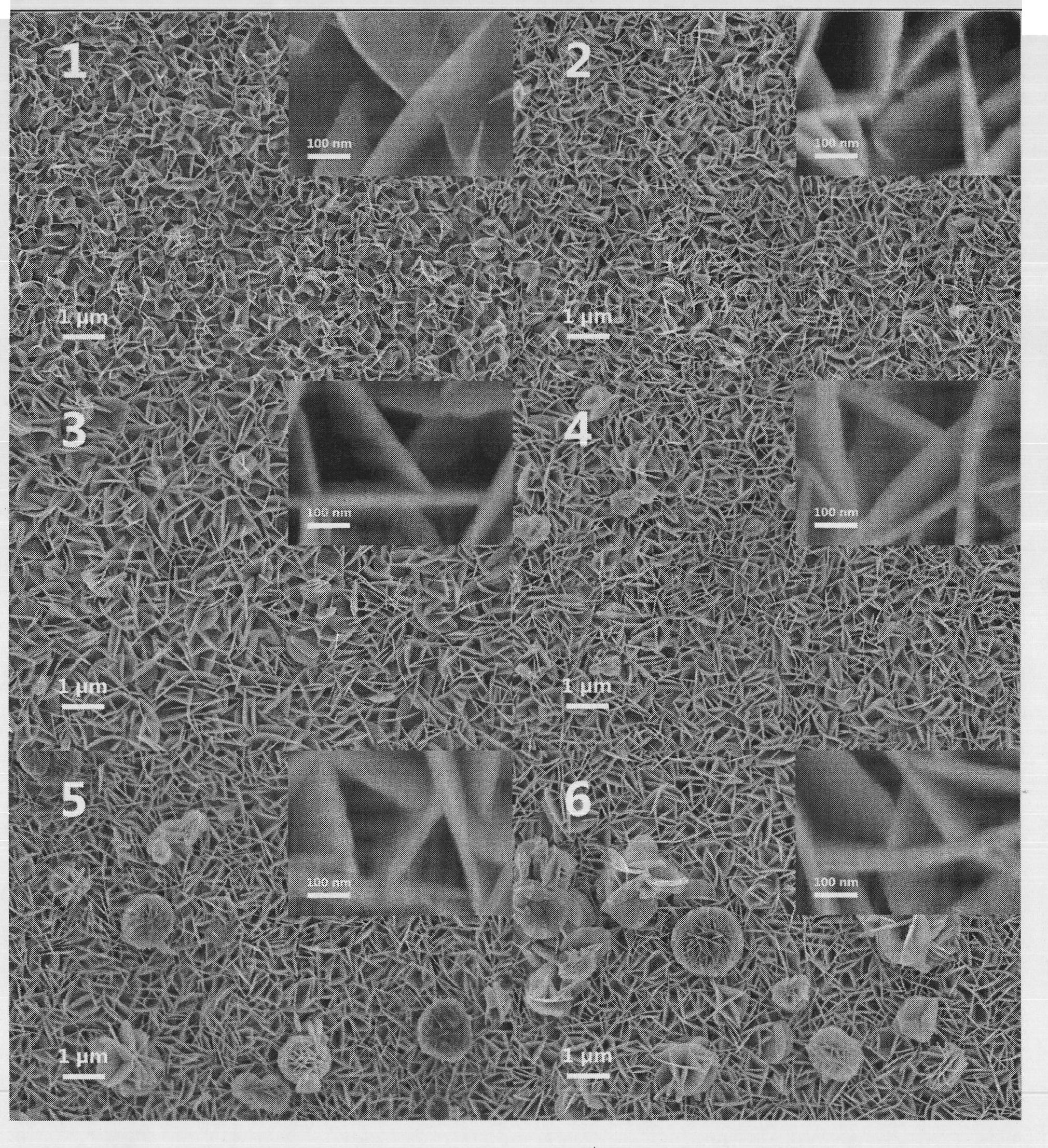

Embodiment 1

[0015] Wash the conductive glass sheet with isopropanol and ethanol and dry it, put it in a 0.1 mol / liter titanium tetrachloride aqueous solution at 50°C for 1 hour, make a titanium dioxide barrier layer on the surface of the conductive glass sheet, take it out and wash it; Bismuth nitrate is added to water to prepare a bismuth ion solution with a concentration of 1 mmol / L; potassium iodide is added to water to obtain an iodide ion solution with a concentration of 1 mmol / L; the conductive glass sheet with a titanium dioxide barrier layer is immersed in the above-mentioned In the two solutions, rinse the residual liquid with water after each immersion, repeat the process 15 times, and obtain a sheet-shaped bismuth oxyiodide nano-film electrode after washing and drying.

[0016] Thin-film electrodes and conductive glass sputtered with platinum are packaged to form a solar cell, and the electrolyte is injected into the electrolyte. The electrolyte solvent is 3-methoxypropionitrile...

Embodiment 2

[0018] Wash the conductive glass sheet with isopropanol and ethanol and dry it, put it in a 0.1 mol / liter titanium tetrachloride aqueous solution at 50°C for 1 hour, make a titanium dioxide barrier layer on the surface of the conductive glass sheet, take it out and wash it; Bismuth nitrate is added to water to prepare a bismuth ion solution with a concentration of 2 mmol / L; potassium iodide is added to water to obtain an iodide ion solution with a concentration of 2 mmol / L; the conductive glass sheet with a titanium dioxide barrier layer is immersed in the above-mentioned In the two solutions, rinse the residual liquid with water after each immersion, repeat the process 30 times, and obtain the sheet-shaped bismuth oxyiodide nano-film electrode after washing and drying.

[0019] The method for measuring the parameters of the obtained thin film solar cell effect is the same as in Example 1, and the results are shown in Table 1.

[0020] Example 3

[0021] Wash the conductive g...

Embodiment 4

[0024] Wash the conductive glass sheet with isopropanol and ethanol and dry it, put it in a 0.1 mol / liter titanium tetrachloride aqueous solution at 50°C for 1 hour, make a titanium dioxide barrier layer on the surface of the conductive glass sheet, take it out and wash it; Bismuth nitrate is added to water to prepare a bismuth ion solution with a concentration of 5 mmol / L; potassium iodide is added to water to obtain an iodide ion solution with a concentration of 5 mmol / L; the conductive glass sheet with a titanium dioxide barrier layer is immersed in the above-mentioned In the two solutions, rinse the residual liquid with water after each immersion, repeat the process 60 times, and obtain the flake-shaped bismuth oxyiodide nano-film electrode after washing and drying.

[0025] The method for measuring the parameters of the obtained thin film solar cell effect is the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com