X-ray developing calcium phosphate cement and preparation method and application thereof

A calcium phosphate bone cement and visualization technology, applied in medical science, prosthesis, etc., can solve the problems of insufficient visualization, unfavorable monitoring of injection and implantation process, etc., achieve good X-ray imaging effect, reduce surgical complications, improve effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

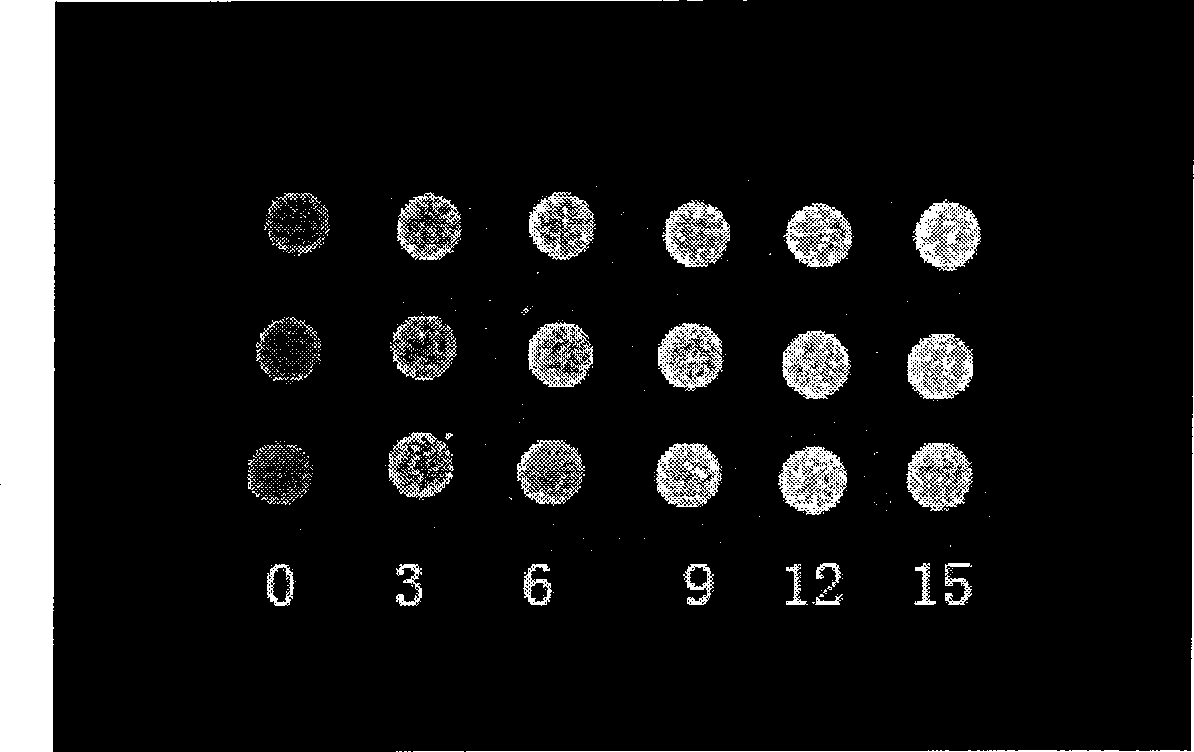

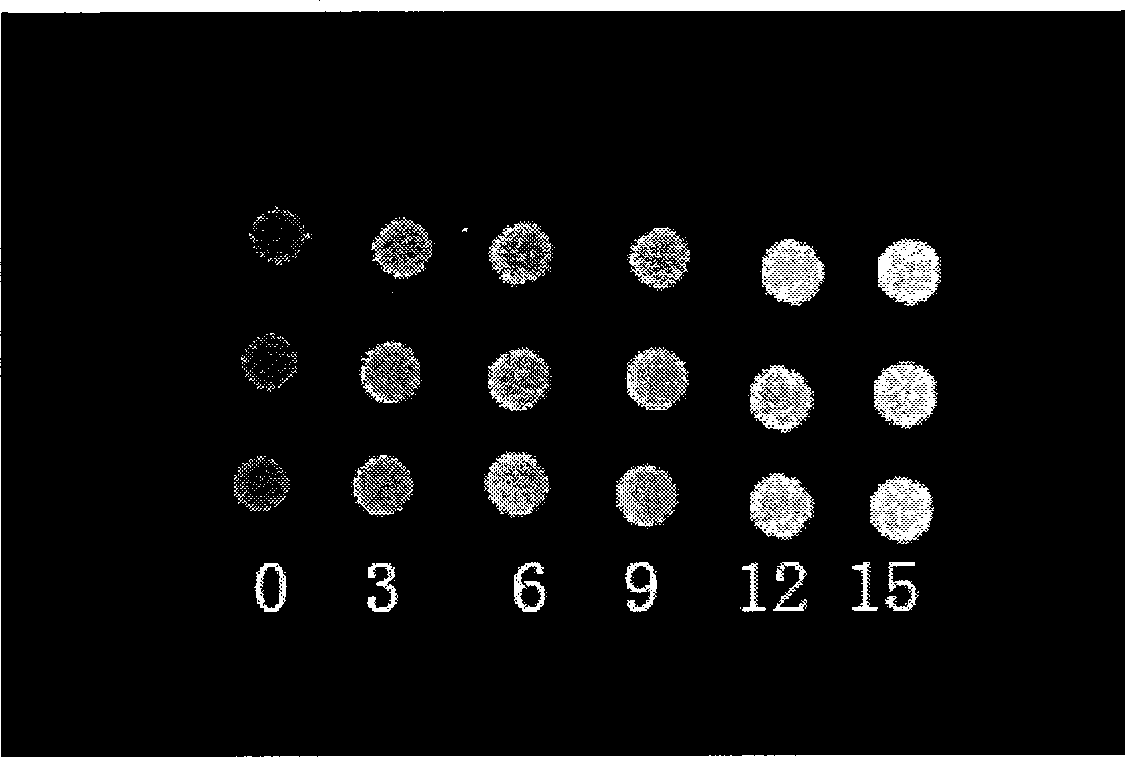

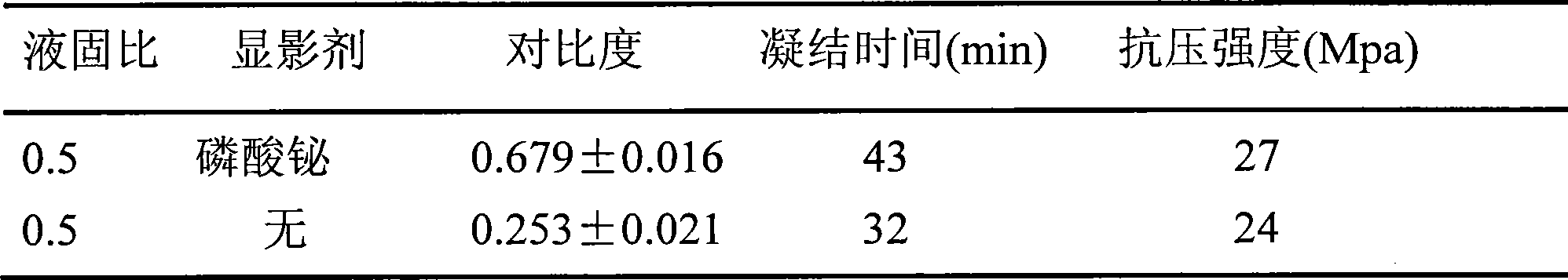

[0027] Preparation of visualized calcium phosphate bone cement using bismuth phosphate as contrast agent:

[0028] (1) Add bismuth phosphate to α-tricalcium phosphate (α-TCP) + calcium hydrogen phosphate dihydrate (DCPD) + calcium carbonate (CaCO 3 ) + hydroxyapatite (HA) + magnesium phosphate (Mg 3 (PO 4 ) 2 )+sodium hydrogen phosphite (NaHSO3 ) system bone cement powder, in which the mass ratio of the developer (bismuth phosphate) to the bone cement powder is 15:100, using dry mixing, grinding in a ball mill for 5 hours, and then passing through a 400-mesh sieve to obtain X-ray Developable calcium phosphate bone cement powder;

[0029] (2) adding mass percentage concentration is that the disodium hydrogen phosphate of 3% and the mass percentage concentration are 0.02% sodium dihydrogen phosphate mixed solution as blending liquid, obtain by the liquid-solid ratio of 0.5mL / g and step (1) X After the light-developable calcium phosphate bone cement powder is fully mixed and ...

Embodiment 2

[0035] Preparation of developable calcium phosphate bone cement using bismuth aluminate as contrast agent:

[0036] (1) Add bismuth aluminate as a developer to the bone cement powder of the amorphous calcium phosphate (ACP) + calcium hydrogen phosphate dihydrate (DCPD) system, where the mass of the developer (bismuth aluminate) and bone cement powder The ratio is 9:100, using wet mixing method, adding ethanol according to the mass ratio of calcium phosphate bone cement powder and ethanol as 1:1, grinding in a ball mill for 2 hours, then drying in an oven at 60°C for 48 hours, and passing 200 mesh sieves to obtain X-ray imaging calcium phosphate bone cement powder;

[0037] (2) Add deionized water as the blending solution, according to the liquid-solid ratio of 0.3mL / g (that is, 1g of calcium phosphate bone cement solid powder plus 0.3mL of water) and the X-ray-developing calcium phosphate bone cement obtained in step (1) After the powder is mixed evenly, a calcium phosphate b...

Embodiment 3

[0043] Preparation of visualized calcium phosphate bone cement using bismuth silicate as contrast agent:

[0044] (1) Add bismuth silicate to tricalcium phosphate (TCP) + calcium hydrogen phosphate dihydrate (DCPD) system bone cement powder, wherein the mass ratio of developer (bismuth silicate) to bone cement powder is 10: 100, using dry mixing, grinding in a ball mill for 3 hours, and passing through a 300-mesh sieve to obtain the powder of X-ray-developing calcium phosphate bone cement;

[0045] (2) Use physiological saline as a concoction solution, mix evenly with the X-ray-developing calcium phosphate bone cement powder obtained in step (1) at a liquid-solid ratio of 0.5mL / g, and obtain X-ray-developing calcium phosphate bone cement powder cement paste.

[0046] The obtained X-ray-visible calcium phosphate bone cement paste is directly implanted into the surgical site through instruments for use, or it is formed into a solidified body in an in vitro human simulation envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com