X-ray developing calcium phosphate cement and preparation method and application thereof

A calcium phosphate bone cement and visualization technology, applied in medical science, prosthesis and other directions, can solve the problems of insufficient visualization, unfavorable injection and implantation process monitoring, etc., achieve good X-ray imaging effect, reduce surgical complications, improve effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

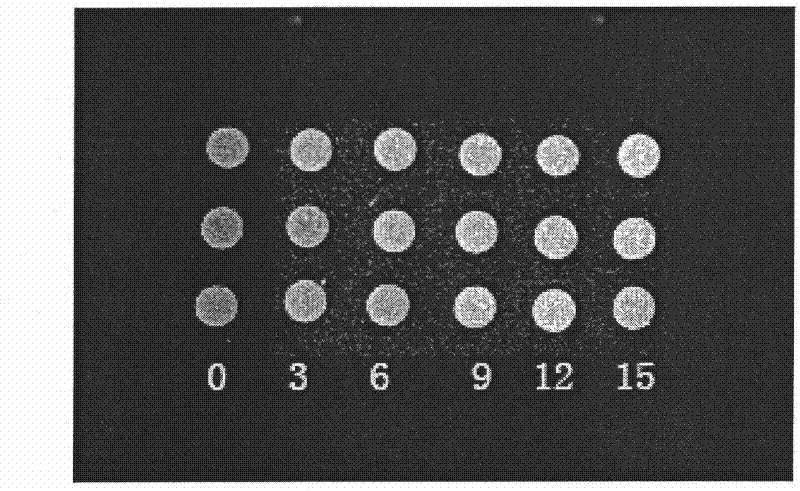

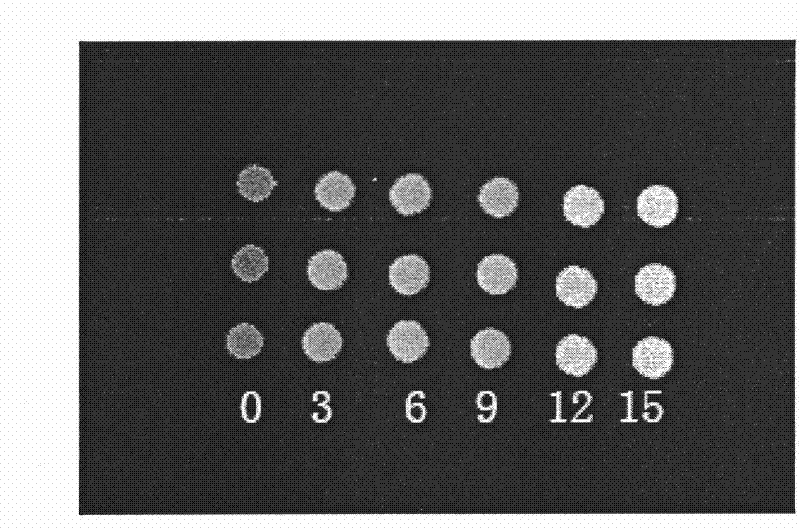

Image

Examples

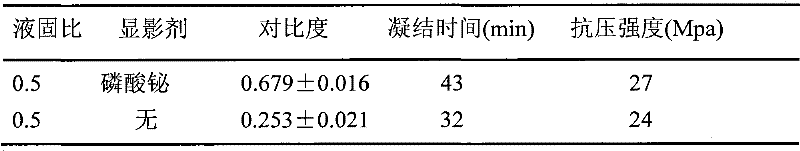

Embodiment 1

[0027] Preparation of visualized calcium phosphate bone cement using bismuth phosphate as contrast agent:

[0028] (1) Add bismuth phosphate to α-tricalcium phosphate (α-TCP) + calcium hydrogen phosphate dihydrate (DCPD) + calcium carbonate (CaCO 3 ) + hydroxyapatite (HA) + magnesium phosphate (Mg 3 (PO 4 ) 2 )+sodium hydrogen phosphite (NaHSO3 ) system bone cement powder, in which the mass ratio of the developer (bismuth phosphate) to the bone cement powder is 15:100, using dry mixing, grinding in a ball mill for 5 hours, and then passing through a 400-mesh sieve to obtain X-ray Developable calcium phosphate bone cement powder;

[0029] (2) adding mass percentage concentration is that the disodium hydrogen phosphate of 3% and the mass percentage concentration are 0.02% sodium dihydrogen phosphate mixed solution as blending liquid, obtain by the liquid-solid ratio of 0.5mL / g and step (1) X After the light-developable calcium phosphate bone cement powder is fully mixed and ...

Embodiment 2

[0035] Preparation of developable calcium phosphate bone cement using bismuth aluminate as contrast agent:

[0036] (1) Add bismuth aluminate as a developer to the bone cement powder of the amorphous calcium phosphate (ACP) + calcium hydrogen phosphate dihydrate (DCPD) system, where the mass of the developer (bismuth aluminate) and bone cement powder The ratio is 9:100, using wet mixing method, adding ethanol according to the mass ratio of calcium phosphate bone cement powder and ethanol as 1:1, grinding in a ball mill for 2 hours, then drying in an oven at 60°C for 48 hours, and passing 200 mesh sieves to obtain X-ray imaging calcium phosphate bone cement powder;

[0037] (2) Add deionized water as the blending solution, according to the liquid-solid ratio of 0.3mL / g (that is, 1g of calcium phosphate bone cement solid powder plus 0.3mL of water) and the X-ray-developing calcium phosphate bone cement obtained in step (1) After the powder is mixed evenly, a calcium phosphate b...

Embodiment 3

[0043] Preparation of visualized calcium phosphate bone cement using bismuth silicate as contrast agent:

[0044] (1) Add bismuth silicate to tricalcium phosphate (TCP) + calcium hydrogen phosphate dihydrate (DCPD) system bone cement powder, wherein the mass ratio of developer (bismuth silicate) to bone cement powder is 10: 100, using dry mixing, grinding in a ball mill for 3 hours, and passing through a 300-mesh sieve to obtain the powder of X-ray-developing calcium phosphate bone cement;

[0045] (2) Use physiological saline as a concoction solution, mix evenly with the X-ray-developing calcium phosphate bone cement powder obtained in step (1) at a liquid-solid ratio of 0.5mL / g, and obtain X-ray-developing calcium phosphate bone cement powder cement paste.

[0046] The obtained X-ray-visible calcium phosphate bone cement paste is directly implanted into the surgical site through instruments for use, or it is formed into a solidified body in an in vitro human simulation envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com