Gold nanorod/TiO2 core-shell nanostructure and its one-step synthesis method

A gold nanorod, titanium dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that are not conducive to the widespread promotion of technology, the loss of gold nanorods, and increase labor costs. The product structure and morphology are easy to control, the repetition rate is high, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

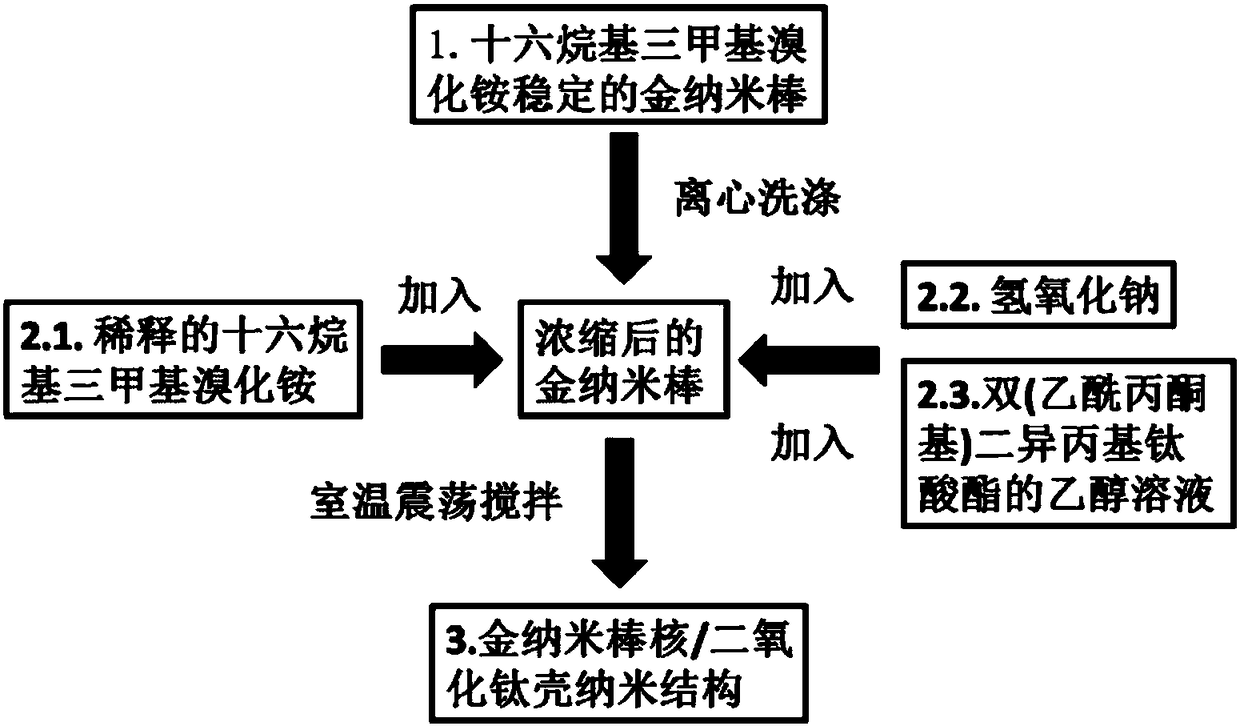

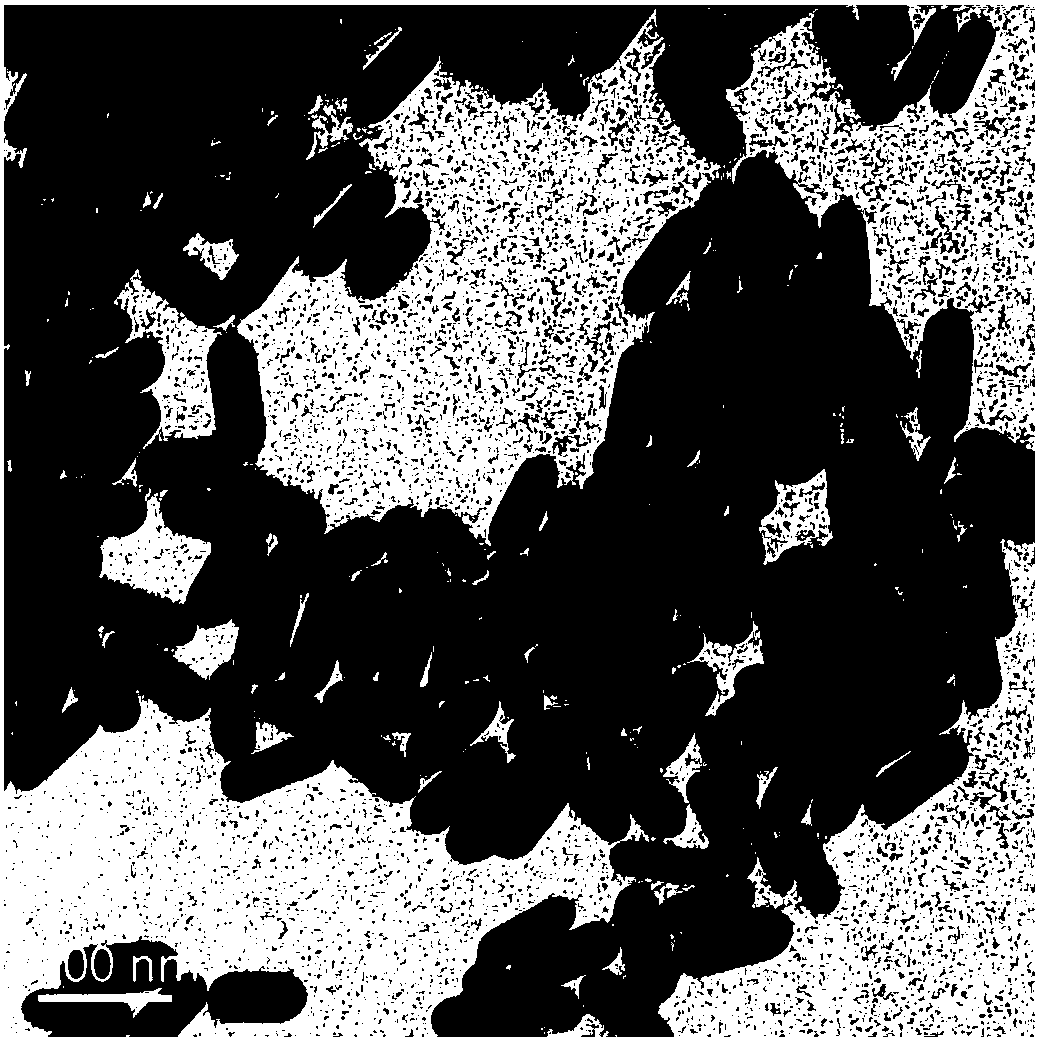

[0031] (1) Using the seed growth method to prepare gold nanorods (refer to J.AM.CHEM.SOC.2010,132,4806–4814) and other documents, but not limited to this, the morphology can be found in figure 1 ;

[0032] (2) Get 10 milliliters of cetyltrimethylammonium bromide-stabilized gold nanorods grown by the seed method in step (1) (the longitudinal plasmon absorption wavelength is 730nm), and centrifuge twice at 8000 rpm for 20 minutes. Then add 1 ml of deionized water to disperse;

[0033] (3) Take 75 microliters of concentrated gold nanorods, add 400 microliters of water to disperse, and then add 20 microliters of 0.01 mol / liter cetyltrimethylammonium bromide aqueous solution;

[0034] (4) Add 2 microliters of aqueous sodium hydroxide solution of 0.1 mol / liter;

[0035] (5) Add 300 microliters of an ethanol solution of bis(acetylacetonato)diisopropyl titanate with a concentration of 0.01 mol / liter, and the reaction system remains in a state of vibration or magnetic stirring during...

Embodiment 2

[0038] (1) Prepare gold nanorods by seed growth method (refer to J.AM.CHEM.SOC.2010, 132, 4806-4814 and other documents), and its morphology is similar to that of Example 1;

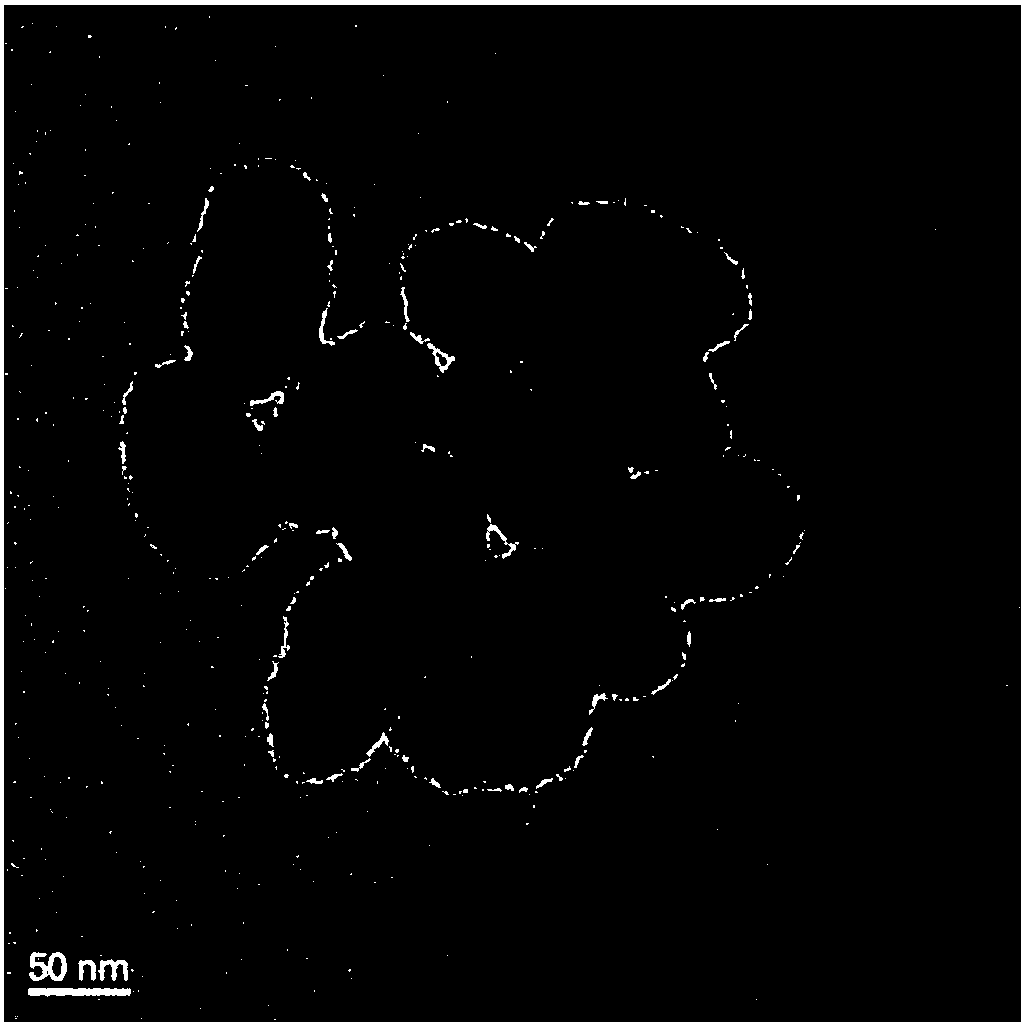

[0039] (2) Take 12 milliliters of cetyltrimethylammonium bromide-stabilized gold nanorods grown by seed method in step (1) (the longitudinal plasmon absorption wavelength is 698nm, please refer to figure 2 ), 8000 rpm, and centrifuged twice in 20 minutes. Then add 1 ml of deionized water to disperse.

[0040] (3) Take 75 microliters of concentrated gold nanorods, add 400 microliters of water to disperse, and then add 20 microliters of 0.01 mol / liter cetyltrimethylammonium bromide aqueous solution.

[0041] (4) Add 2 microliters of 0.1 mol / liter sodium hydroxide aqueous solution.

[0042] (5) Add 120 microliters of an ethanol solution of bis(acetylacetonyl)diisopropyl titanate with a concentration of 0.01 mol / liter. During the addition process, the reaction system was kept in a shaking or magnetic sti...

Embodiment 3

[0045] (1) Prepare gold nanorods by seed growth method (refer to J.AM.CHEM.SOC.2010, 132, 4806-4814 and other documents), and its morphology is similar to that of Example 1;

[0046] (2) Get 14 milliliters of cetyltrimethylammonium bromide-stabilized gold nanorods (longitudinal plasmon absorption wavelength is 675nm) grown by the seed method in step (1), centrifuge twice at 8000 rpm for 20 minutes. Then add 1.5 ml of deionized water to disperse.

[0047](3) Take 75 microliters of concentrated gold nanorods, add 800 microliters of water to disperse, and then add 20 microliters of 0.01 mol / liter cetyltrimethylammonium bromide aqueous solution.

[0048] (4) Add 2 microliters of 0.1 mol / liter sodium hydroxide aqueous solution.

[0049] (5) Add 150 microliters of an ethanol solution of bis(acetylacetonyl)diisopropyl titanate with a concentration of 0.01 mol / liter. During the addition process, the reaction system was kept in a shaking or magnetic stirring state.

[0050] (6) Reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com