Method for treating solid waste in low-carbon mode and restraining generation of dioxin

A solid waste and carbon treatment technology, applied in the combustion method, indirect carbon dioxide emission reduction, combustion type and other directions, can solve the problem of high treatment cost, and achieve the effect of reducing carbon emission, low cost and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A low-carbon method for treating solid waste and inhibiting the formation of dioxins, comprising the following steps:

[0029] S1: Use a shredder to crush solid waste into solid fuels with a particle size of less than 1mm. The solid waste includes municipal solid waste, sludge, medical waste, industrial combustible waste, waste biomass, and other solid wastes containing Cl elements. The solid wastes containing Cl elements include plastics, which are additionally added during the preparation process. The Cl element or the molecular formula includes the Cl element, such as polyvinyl chloride.

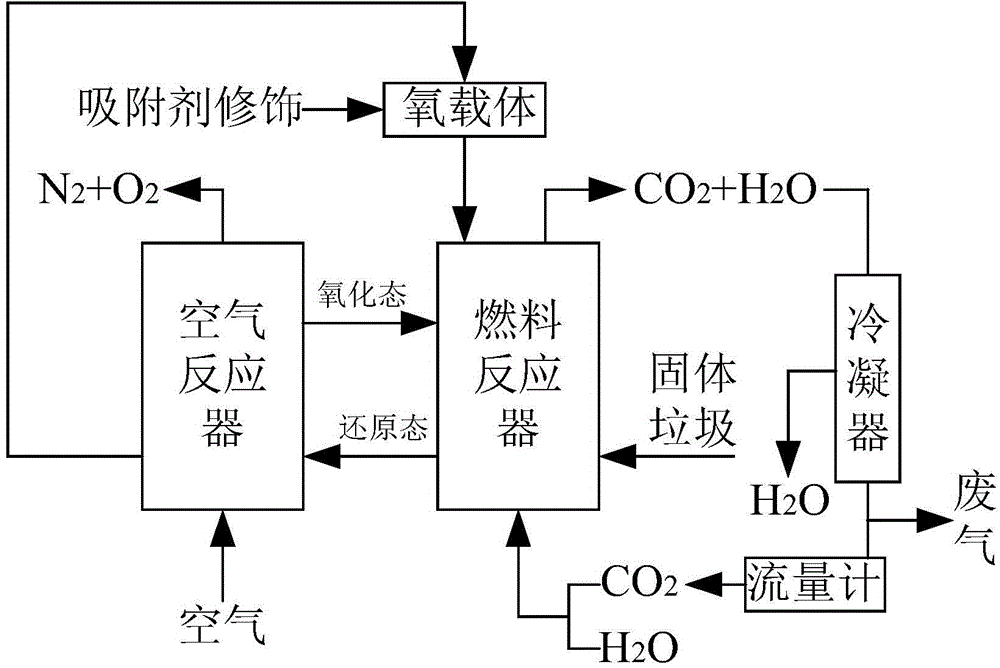

[0030] S2: Carry out chemical looping combustion treatment on the pulverized solid waste. The chemical looping combustion temperature is 850°C-1000°C. The chemical looping combustion uses an oxygen carrier modified by an adsorbent, and the oxygen carrier is iron ore. Crush the iron ore, and then obtain iron ore particles with a particle size of 0.1 mm to 0.3 mm by sieving. The ad...

Embodiment 2

[0032] S1: Use a shredder to crush solid waste into solid fuels with a particle size of less than 1mm. The solid waste includes municipal solid waste, sludge, medical waste, industrial combustible waste, waste biomass, and other solid wastes containing Cl elements. The solid wastes containing Cl elements include plastics, which are additionally added during the preparation process. The Cl element or the molecular formula includes the Cl element, such as polyvinylidene chloride.

[0033] S2: Perform chemical looping combustion treatment on the pulverized solid waste. The chemical looping combustion temperature is 800°C-900°C. The chemical looping combustion uses an oxygen carrier modified by an adsorbent, and the oxygen carrier is copper ore. Crush copper ore, and then obtain copper ore particles with a particle size of 0.1mm to 0.3mm by sieving. The adsorbent used is NaNO 3 , the NaNO 3 Dissolved in deionized water for wet impregnation modification of copper ore. Lattice oxyg...

Embodiment 3

[0035] S1: Same as Example 1.

[0036] S2: Carry out chemical looping combustion treatment on the pulverized solid waste. The chemical looping combustion temperature is 800°C-900°C. The chemical looping combustion uses oxygen carriers modified by adsorbents. The oxygen carrier is manganese ore, which is pulverized first. Manganese ore, and then obtain manganese ore particles with a particle size of 0.1mm to 0.3mm by sieving, using adsorbent K 2 CO 3 It is dissolved in deionized water for ultrasonic wet impregnation modification of manganese ore, and the frequency of ultrasonic wave is 10-50KHz. Lattice oxygen is used to complete solid waste incineration, condenses and captures carbon dioxide produced by chemical chain combustion, and adsorbs and fixes gaseous chlorine with adsorbents to achieve low-carbon emissions in waste treatment and inhibit the formation of dioxins. The ultrasonic wet impregnation process is a method of wet impregnation under ultrasonic waves, which hel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com