Treatment system for reducing household refuse incineration smoke Dioxin and application method

A technology of domestic waste incineration and treatment system, which is applied in the field of processing technology for flue gas pollutants of domestic waste incineration, can solve the problems of difficult, difficult and high cost of odor treatment, achieve the suppression of NOx generation, prevent leakage, and reduce dioxins English generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

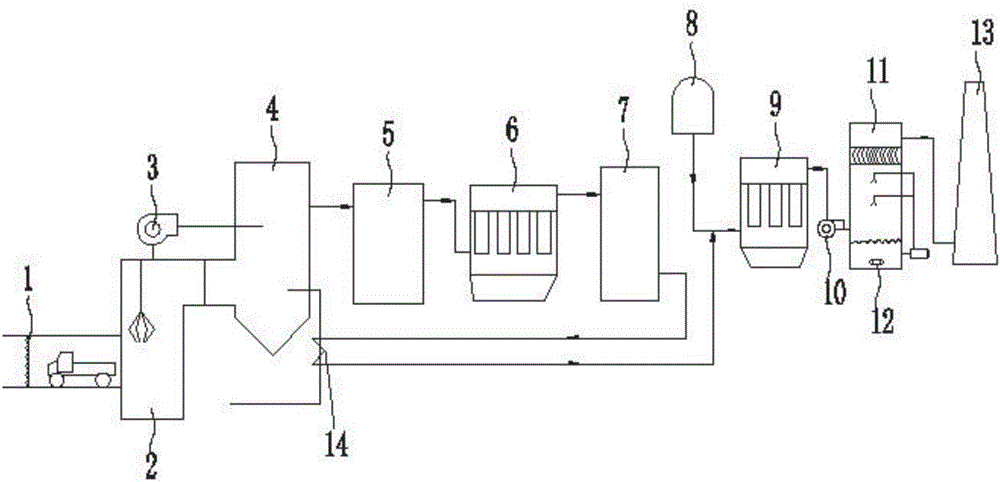

[0077] Embodiment 1 is a daily processing 800t / d waste incineration power plant

[0078] The transport truck drives into the discharge port, the air curtain is closed, the door of the garbage storage pit is opened, and the garbage is discharged into the garbage storage pit. Under the action of the strong induced draft fan, the odorous gas does not leak out. After the garbage unloading is completed, the door of the garbage storage pit is closed. The strong induced draft fan continues to work, sending the malodorous gas from the garbage storage pit into the garbage incinerator for harmless incineration, deodorizing and generating heat. Add coal with high sulfur content (3-6% sulfur content) in the main combustion chamber of the garbage incinerator to support combustion, so that the S / Cl ratio can be increased to more than 5, and the garbage is incinerated in the main combustion chamber at 850°C-900°C ; The incineration flue flows through the secondary combustion chamber and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com