Low-nitrogen-oxide gas combustor and combustion method of combustor

A low-nitrogen oxide, burner technology, applied in combustion methods, gas fuel burners, burners, etc., can solve the problem of insufficient combustion, uneven temperature field of gas burners, and inability to control pollutants well, etc. problem, to achieve the effect of uniform flame temperature and inhibition of nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

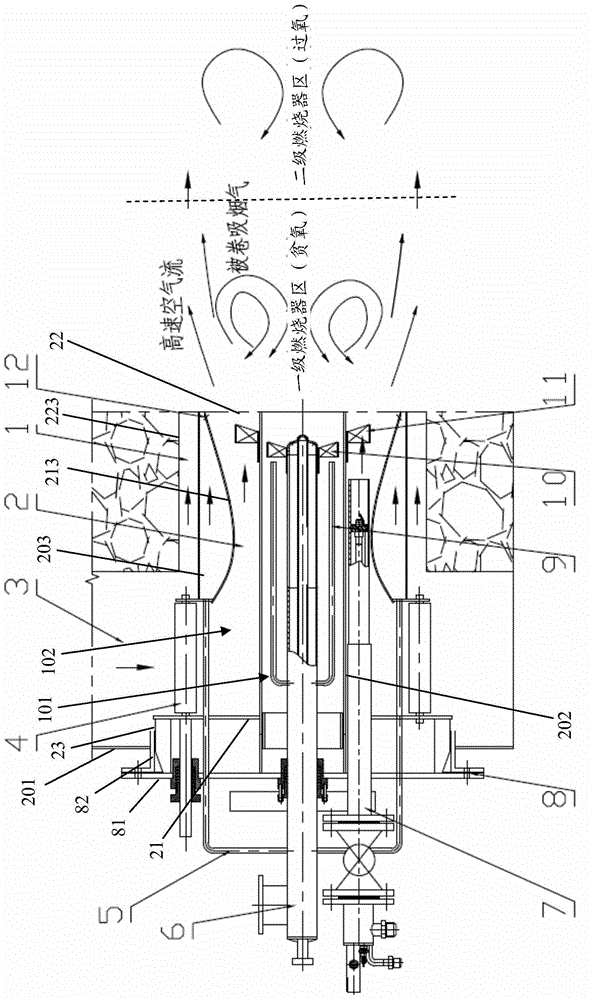

[0021] like figure 1 As shown, the low NOx burner of the present invention is a cylindrical structure, which includes a casing 201, a central sleeve 202, an outer gas cavity 203, a regulating damper 4, a gas main pipe 6, an ignition gun 7, an installation port 8. Outer layer gas pipe 5, central gas nozzle 9, primary cyclone 10, secondary cyclone 11.

[0022] Wherein, the installation port 8 is composed of a vertical mouth baffle 81 and an annular surrounding plate 82 connected to the edge of the mouth baffle 81 .

[0023] The gas main pipe 6 is located in the center of the burner, passes through the mouth baffle 81 of the installation port 8, and extends toward the furnace; the outer gas pipes 5 and the central gas nozzle 9 are several, and are arranged circumferentially symmetrically around the gas main pipe 6. , and are all communicated with the gas main pipe 6, wherein the central gas nozzle 9 is arranged in the center, and the outer layer gas pipe 5 is arranged in the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com