Application of novel pipeline industrial gas in metal cutting and kiln heating

A technology for industrial gas and metal cutting, applied in metal processing equipment, lighting and heating equipment, adjusting fuel supply and other directions, can solve problems that have not been documented in any literature, and achieve the elimination of human factors, high speed, and cutting speed. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A certain unit uses pipeline natural gas on the HJZCGD-1500 cantilever type large-section flame cutting machine, and through the TANRANQIQI device with rare earth polymerization agent to make a new type of industrial gas to cut the material is P91, and the diameter specifications are 800mm, 900mm, 1150mm, 1400mm steel ingots.

[0032] Use natural gas to cut steel ingots with a diameter of 800mm, and the natural gas consumption is 9m 3 , the cost is 2.02 yuan / m 3 ×9m 3 = 18.18 yuan; using new industrial gas to cut P91 steel ingots with a diameter of 800mm, the natural gas consumption is 3m 3 , the addition amount of rare earth polymerizer is 5g / m 3 . The cost is (2.02 yuan / m 3 +0.2 yuan / g×5)×3m 3=9.06. Cost savings of 9.12 yuan.

[0033] Use natural gas to cut P91 steel ingots with a diameter of 900mm, and the natural gas consumption is 12m 3 , the cost is: 2.02 yuan / m 3 ×12m 3 = 24.24 yuan; using new industrial gas to cut P91 steel ingots with a diameter of 90...

Embodiment 2

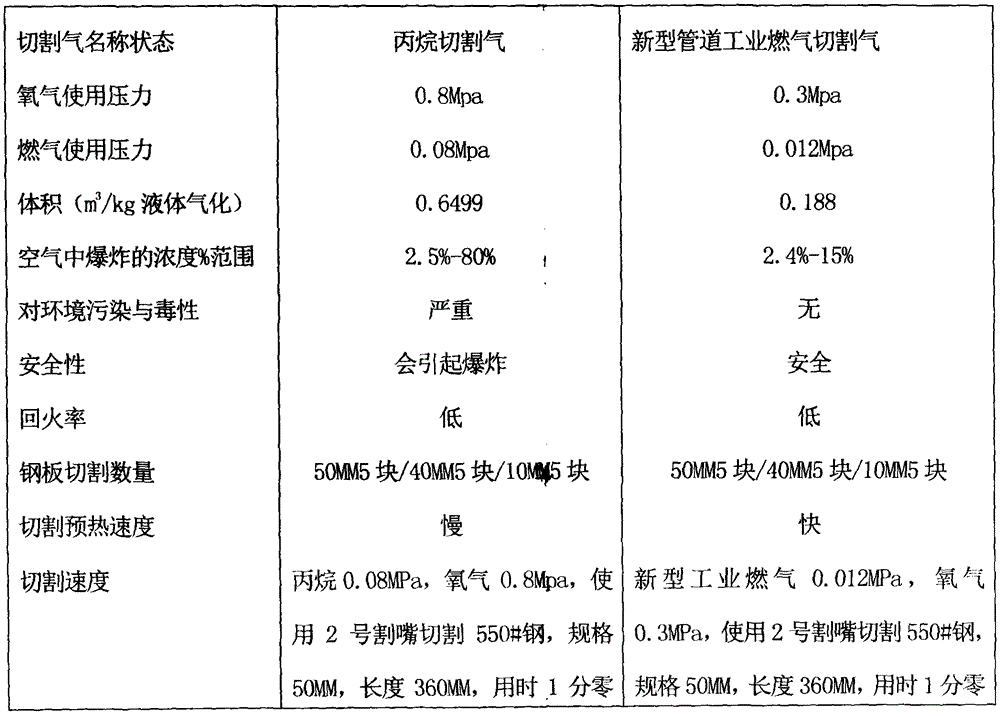

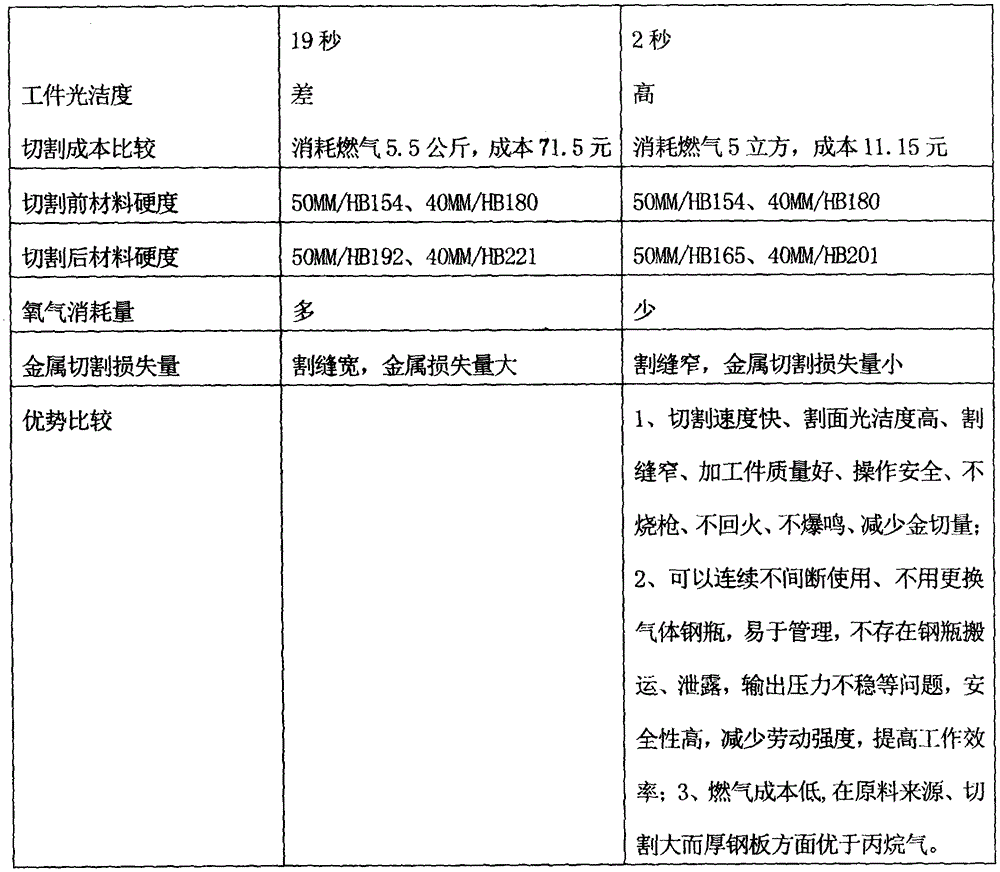

[0045] A certain unit used new type of industrial gas on profiling flame cutting machine and semi-automatic flame cutting machine to cut steel plate with thickness of 10mm / 40mm / 50mm and material of Q550, and achieved obvious social and economic benefits. The original cutting gas used by the unit was propane gas, which was supplied by 50kg gas cylinders, with an annual consumption of more than 2,000 cylinders, and the gas cost was about 1.4 million yuan. Later, the new technology of cutting steel with new industrial gas is adopted, and the pressure of the natural gas reaction control device and the natural gas pipeline at room temperature is 0.012MPa. Compared with the cost of using bottled propane cutting gas, the cost is reduced by about 65%, and the annual economic benefit is about 900,000 yuan. The comparison of relevant technical indicators of the two gas-cut steel materials is shown in Table 1:

[0046] Table 1 Comparison of technical indicators of two kinds of gas cutti...

Embodiment 3

[0054] The specific implementation of the use of new industrial gas in the furnace heating of the vehicle bottom drying furnace of a certain unit is as follows:

[0055] The car bottom drying furnace is used for uniform temperature drying of processed parts, and its structure is composed of furnace body, trolley, heating device, control system and other parts. Combustion system: 25mm burners are selected, 5 groups are installed in total, and the natural gas consumption is 1300M 3 / h. In order to change the large consumption of natural gas, poor effective utilization rate, low flame temperature, high carbon monoxide emission, low qualified rate of workpieces, when the peak gas consumption comes, the flow of natural gas decreases, the temperature required by the kiln cannot be guaranteed, and the operation of the kiln is affected. In this situation, it is decided to adopt a new pipeline industrial gas heating and energy-saving technology. The natural gas pressure regulating dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com