Absorption Type-Removal/Condensing Apparatus

A concentration device and absorption technology, which is applied in the field of absorption removal and concentration devices, can solve the problems of impossibility, deterioration, expensive energy consumption, etc., and achieve the effects of preventing the air supply from being too dry, reducing energy loss, and avoiding insufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

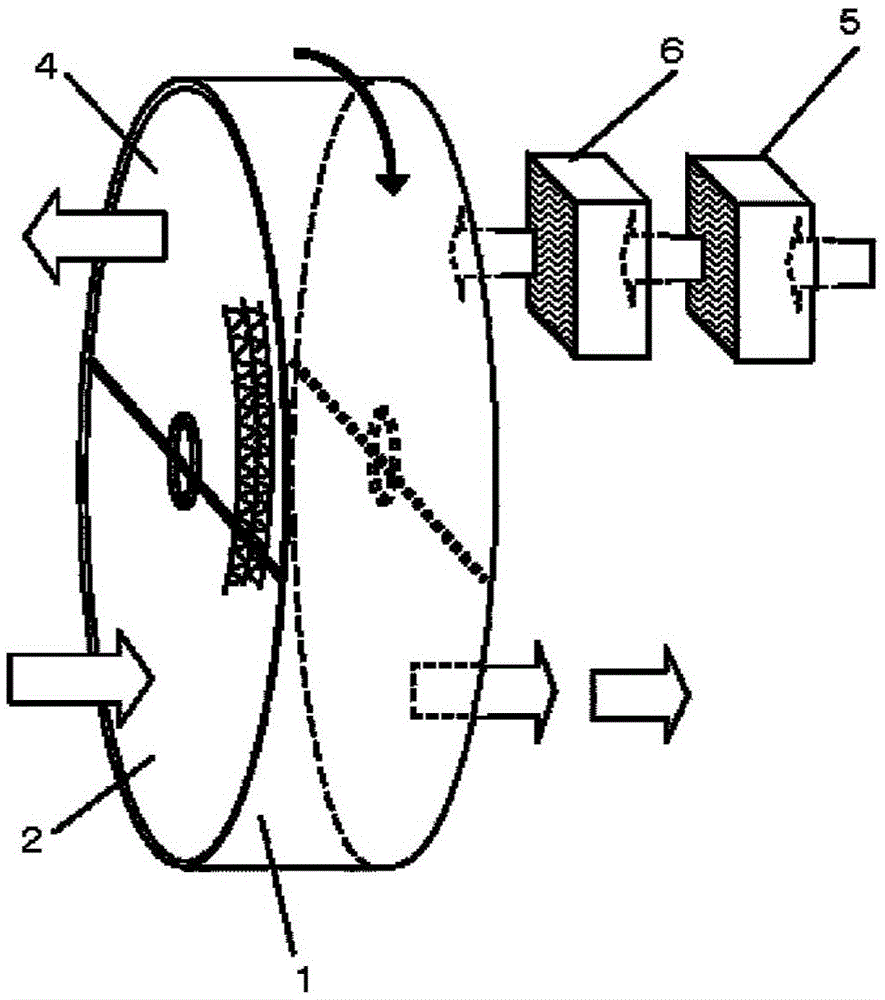

[0057] Below, based on figure 1 Embodiments of the absorption type removal and separation apparatus of the present invention will be described in detail. 1 is a honeycomb rotor, which is processed by processing non-combustible sheets such as ceramic fiber paper into cell stripes (with waves) and wound into a rotor shape, loaded with potassium carbonate (potassium bicarbonate), carbonic acid Inorganic absorbents such as sodium (sodium bicarbonate), organic absorbents such as triethylethanolamine and monoethanolamine, or weakly basic ion exchange resins.

[0058] The honeycomb rotor 1 is divided into a treatment zone 2 and a regeneration zone 4 . In the processing area 2, indoor air is supplied by a fan etc. (it is a normal fan, so it is not shown in figure).

[0059] The air to be treated is ventilated in the treatment area 2, and the carbon dioxide contained in the air to be treated is absorbed by the absorbent in the rotor part and separated and removed from the air to be t...

Embodiment 2

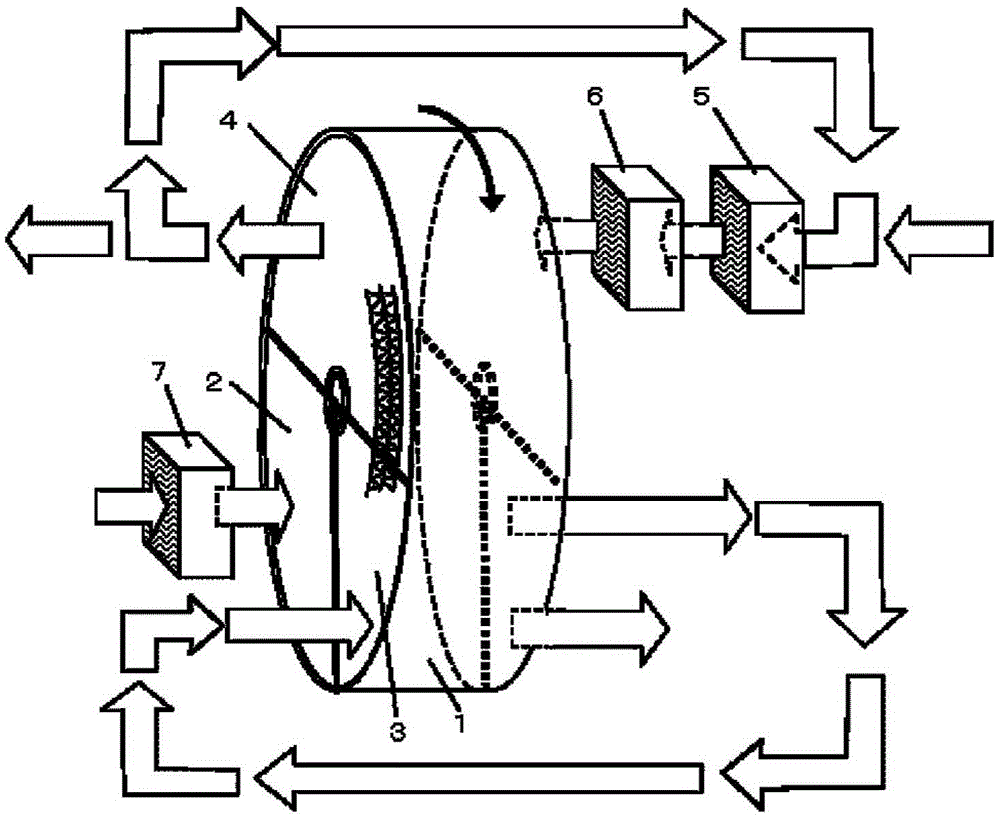

[0062] Such as figure 2 As shown, the honeycomb rotor 1 is divided into a treatment area 2 , a treatment area 3 and a regeneration area 4 . In the processing area 2, indoor air is supplied by a fan etc. (it is a normal fan, so it is not shown in figure).

[0063] The air to be treated passes through the humidifying unit 7 for treatment, and is ventilated in the treatment area 2, so that the carbon dioxide contained in the air to be treated is absorbed by the absorbent in the rotor portion and separated from the air to be treated. Then, a part or all of the treated outlet air is passed through the treatment zone 3 to remove carbon dioxide, thereby reducing the concentration of carbon dioxide.

[0064] In the regeneration zone 4, the used regeneration air that has passed through the regeneration zone 4 is mixed with the outside air, and the regeneration air heated by the heater 5 is ventilated in the regeneration humidification unit 6, so that the absorbed carbon dioxide is us...

Embodiment 3

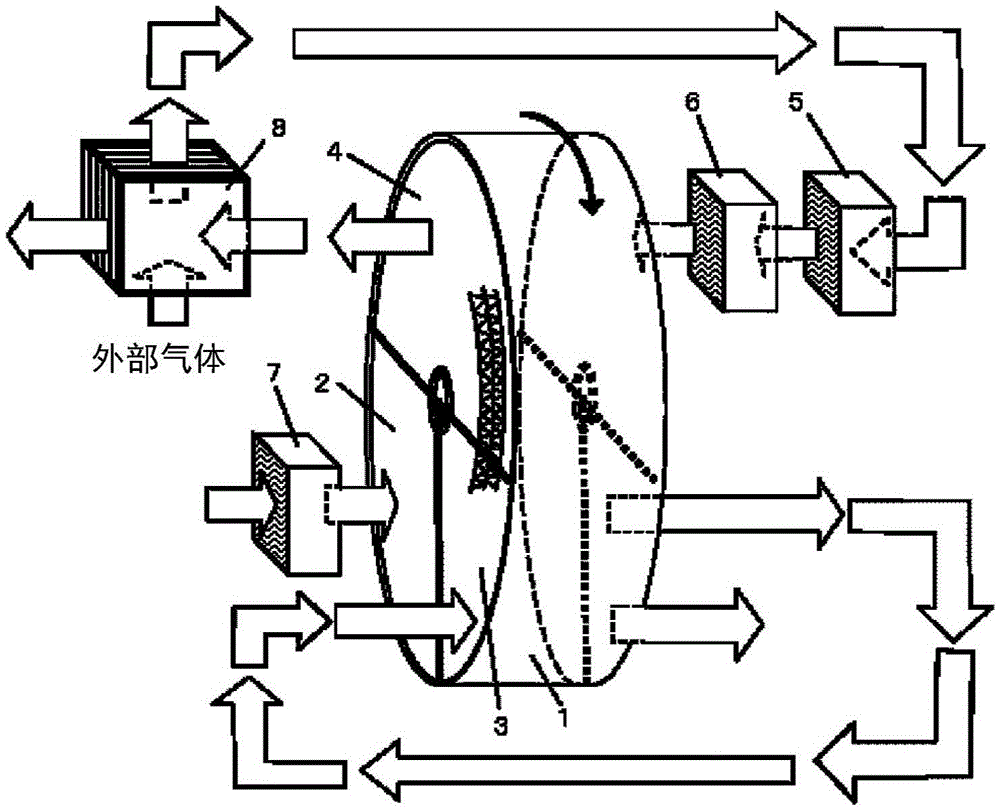

[0066] Such as image 3 As shown, the enthalpy is recovered and the regeneration energy is reduced by making the regeneration outlet air and the external air of Example 2 pass through different flow paths of the total heat exchanger 8 respectively. Not only the second embodiment but also other embodiments can combine the total heat exchanger to exchange heat between the regeneration outlet air with high enthalpy and the external air for regeneration, so as to achieve the energy saving effect.

[0067] The above is the description of the structure of the absorption type removal and concentration device. Taking the embodiment 2 as an example, the operation will be described while adding air conditions. first, Figure 4 The example shown is an example of comparing the concentration of carbon dioxide at the outlet of the regeneration zone when the absolute humidity of the low-temperature regeneration air (55°C) is 4 to 30 g / kg' (carbon dioxide concentration: 450 ppm). The condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com