Curved bridge fitting laying structure based on orthogonal prefabricated beam plate and laying method thereof

A technology of curved bridges and prefabricated girders, applied in the field of bridge structures, can solve the problems of complex internal force distribution of transverse bridge slabs, affect the continuity of bridge decks between spans, increase the complexity of assembly construction, etc., achieve reasonable and ingenious layout methods, and simplify design calculations , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

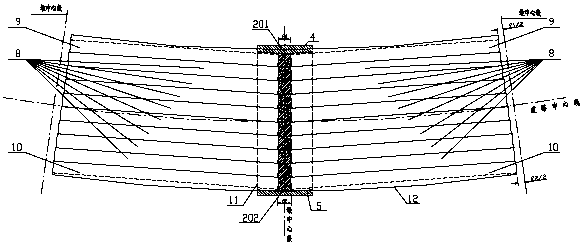

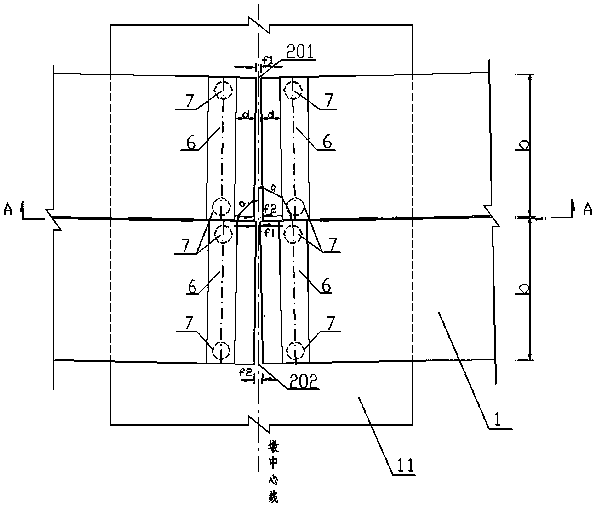

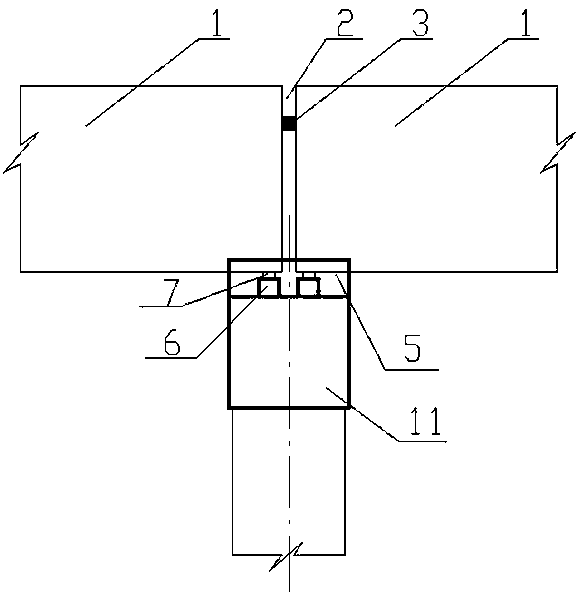

[0035] Explanation of parameters of the present invention: In the present invention, n is the number of bridge piers; m is the number of girder slabs in each span; R is the radius of the curved bridge; L0 is the reference span length of the orthogonal prefabricated girder slab 1; α is the center line of the slab The angle between the direction (tangential to the chord) and the centerline of the cap beam (radial), see figure 2 ; b is the width of the orthogonal prefabricated beam slab 1; f1 is the width of the inner plate seam 201; f2 is the width of the outer plate joint 202.

[0036]The curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com