Design Method of Quasi-Double Lead Cone Worm Gear

A design method, technology of bevel and worm, applied in mechanical equipment, belt/chain/gear, portable lifting device, etc., can solve problems such as complex technical principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

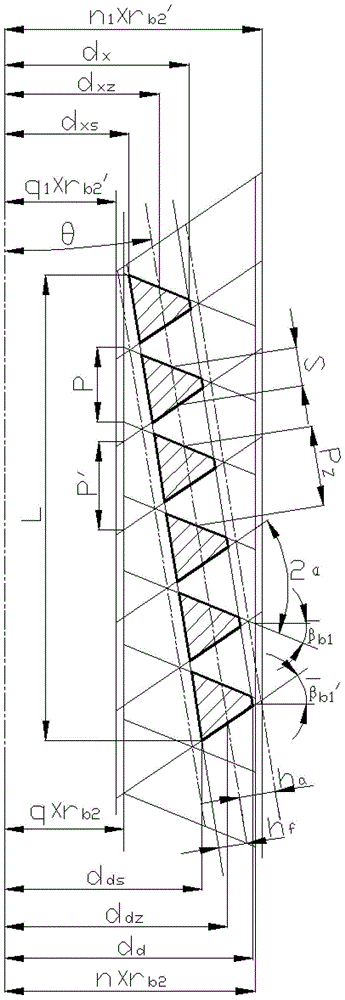

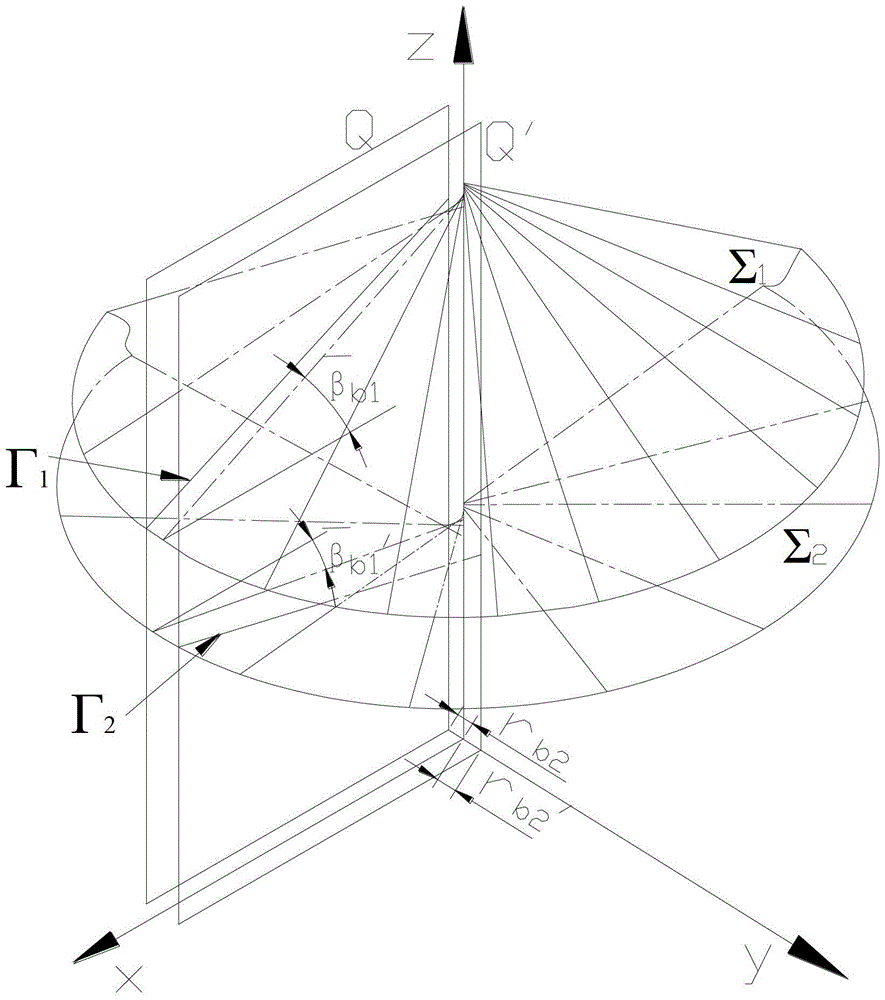

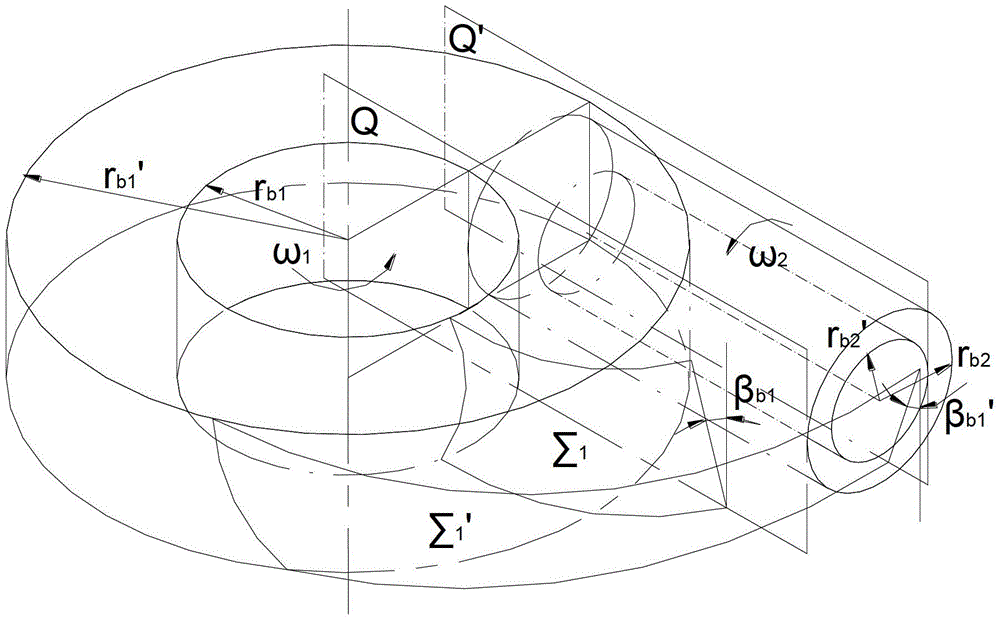

[0386] 1. Known parameters: number of worm gear teeth z=70, worm gear modulus m=2.823922172mm;

[0387] Quasi-double-lead cone worm: number of quasi-double-lead cone-worm heads=1, quasi-double-lead cone-worm modulus m=2.823922172mm, quasi-double-lead cone-worm external meshing side shaft profile angle Tooth profile angle of quasi-double-lead tapered worm internal meshing side shaft section The outer diameter of the large end of the quasi-double-lead tapered worm d d =51mm;

[0388] Quasi-double lead bevel worm gear pair: axis stagger angle ψ=90°, number of meshing teeth k=7.

[0389] 2. The steps of the design method of quasi-double-lead conical worm gear pair are as follows:

[0390] (1) Design the natural tooth profile angle α of the quasi-double-lead conical worm:

[0391] in accordance with It is calculated that α=52.643221608364868°;

[0392] (2) Design the approximate tooth profile angle β in the Q-Q section of the outer meshing surface of the quasi-double-lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com