Assembled ultra-narrow gap MAG/MIG welding insulating spray nozzle

An insulating nozzle and narrow gap technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of short service life, uneven heating, nozzle cracking, etc., and achieve low manufacturing cost, increased working life, cracking and damage. The effect of failure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

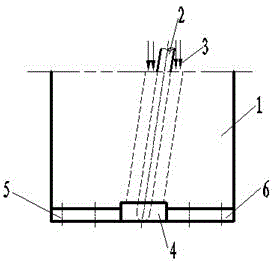

[0016] One, at first introduce the structure of the present invention.

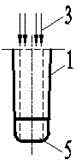

[0017] The assembled ultra-narrow gap MAG / MIG welding insulating nozzle involved in the present invention is composed of two groups of parts, one group is the front and rear insulating plates 4, and the other group is the left insulating strip 5 and the right insulating strip 6; the front and rear insulating plates 4 are plates The upper part of the left and right sides is equipped with a protruding tenon structure; the left insulating strip 5 and the right insulating strip 6 are bar structures, one end has a protruding tenon structure, and there are two external tenon structures on the outer side of the upper part. The concave groove is used for the positioning and connection of the outer tenon structure of the front and rear insulation boards 4; a cylindrical boss 7 with a diameter of 3mm is provided in the center of the width above one end of the left insulation strip 5 and the right insulation strip 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com