Contour method for machining elliptic cam

A technology of elliptical cam and profiling processing, which is applied to belt grinders and other directions to achieve the effect of simple method, quality assurance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

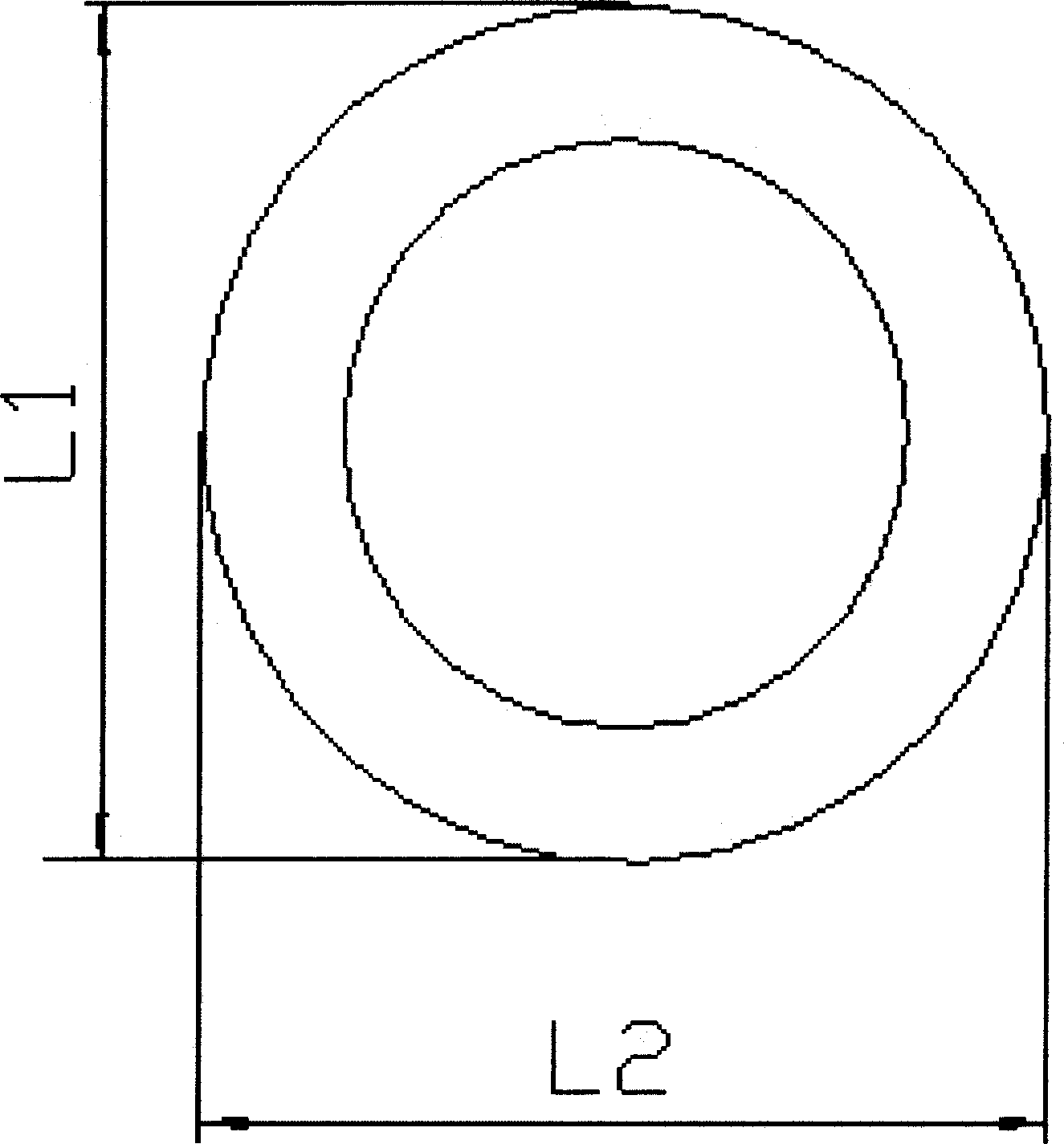

[0010] The embodiment of the present invention: the processed elliptical cam such as figure 1 As shown, the shape is an ellipse, the major axis L1=37.54, the tolerance requirement is upper deviation +0.008, the lower deviation -0.008; the minor axis L2=36.46, the tolerance requirement is upper deviation +0.005, and the lower deviation -0.008. The method is as follows:

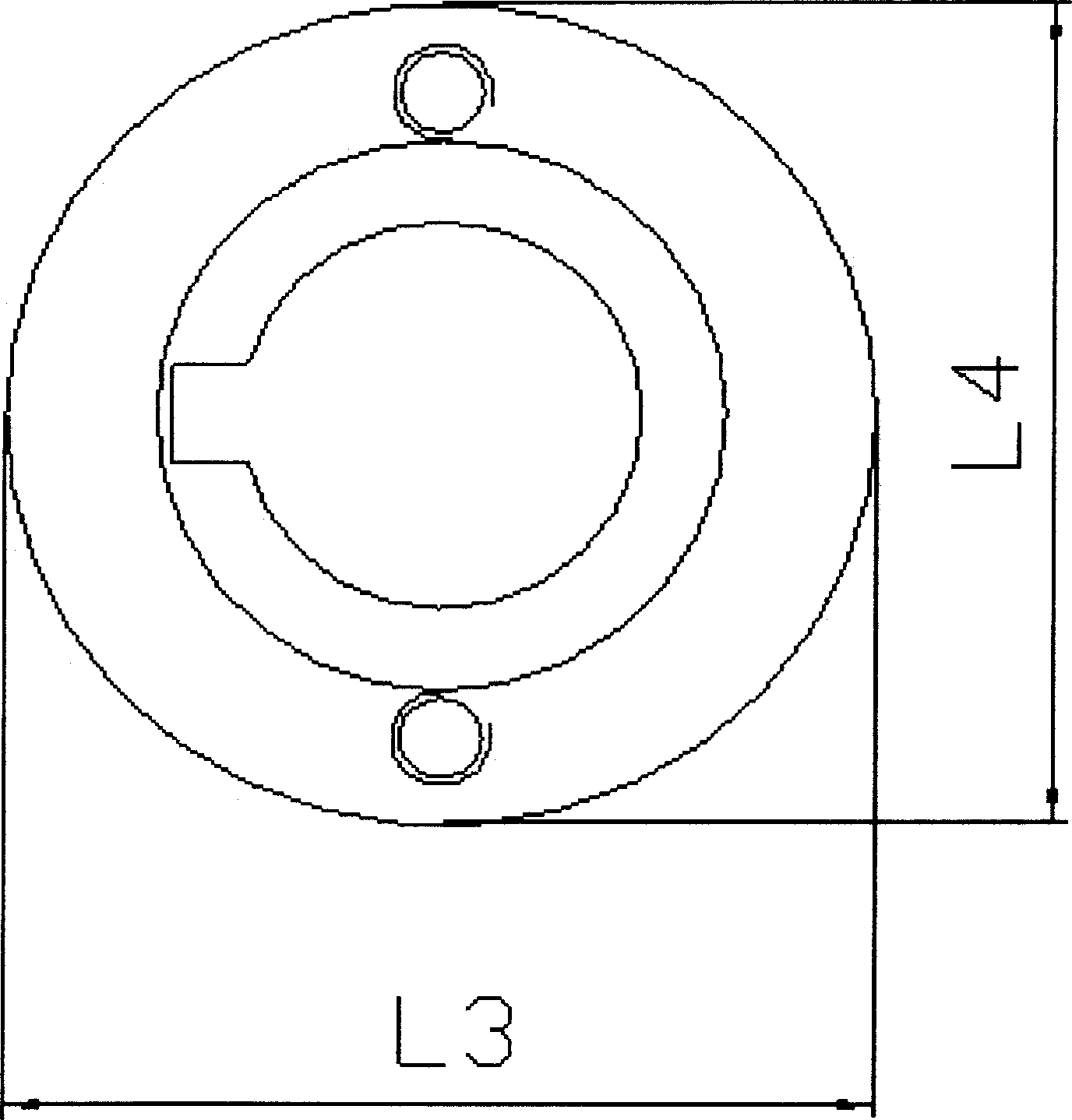

[0011] First, make a relief grinding elliptical cam. According to the shape of the processed elliptical cam, the relief grinding elliptical cam is designed such as figure 2 As shown, its shape is also elliptical, the major axis L3=51.96, the tolerance requirement is upper deviation +0.005, the lower deviation -0.005; the minor axis L4=50.88, the tolerance requirement is upper deviation +0.005, and the lower deviation -0.005;. Made of wear-resistant materials, it is not deformed, wear-resistant, and has a long service life.

[0012] Secondly, install the finished elliptical cam on the camshaft of the hob shovel gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com