Tool for bending electrostatic ring lead of transformer

An electrostatic ring and transformer technology, which is applied in the field of transformer manufacturing, can solve the problems of low production efficiency of transformer electrostatic rings, unguaranteed dimensional accuracy, uneven surface, etc., and achieves the effect of easy to ensure dimensional accuracy, smooth appearance and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

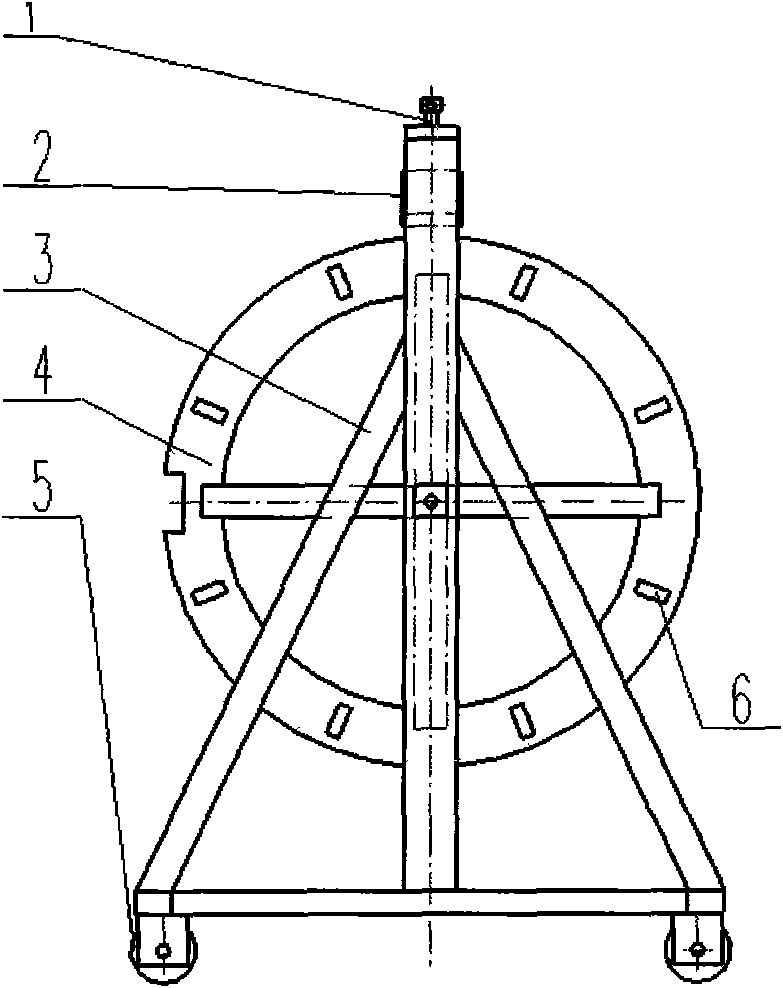

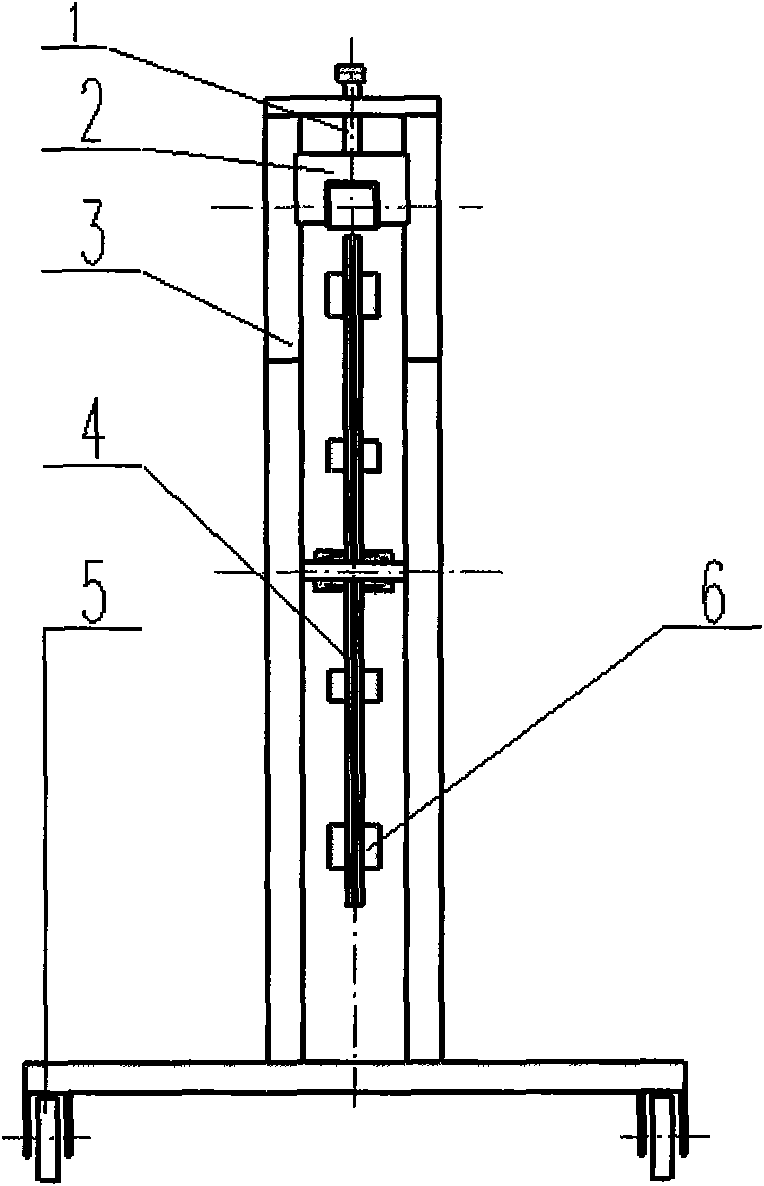

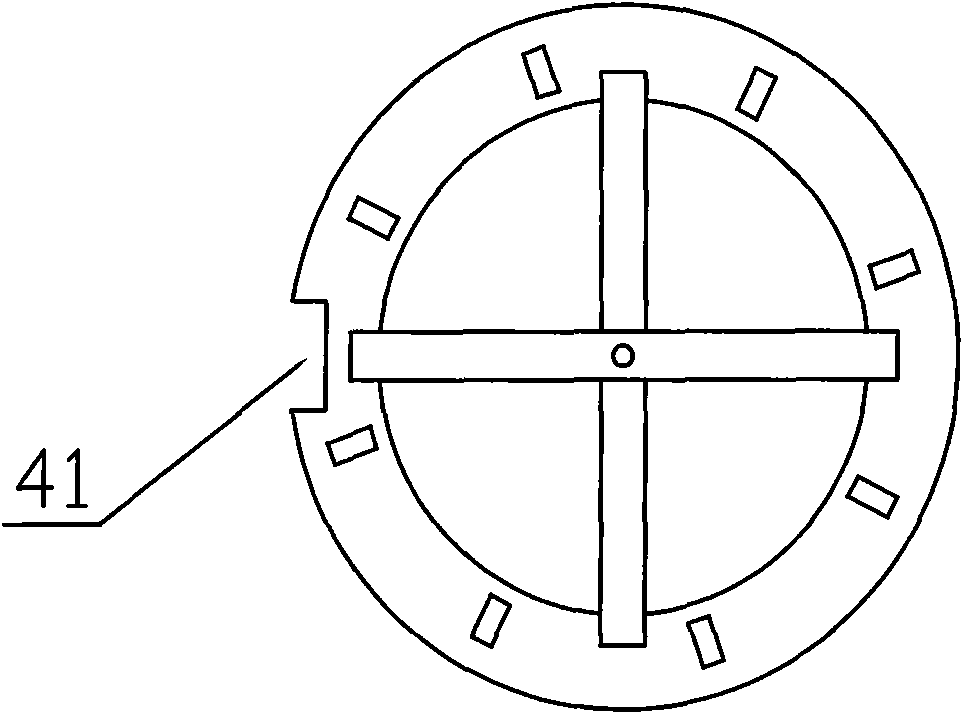

[0023] figure 1 It is the front view of the wire bend of the electrostatic ring of the transformer of the present invention, figure 2 It is a side view of the transformer static ring wire Weibend of the present invention, Figure 4 It is a schematic cross-sectional view of the transformer electrostatic ring wire Weibending tooling rotating disk structure of the present invention, as figure 1 , figure 2 , Figure 4 As shown, the rotating disk 4 is mounted on the bracket 3 through a shaft, and a groove suitable for the thickness of the flat copper wire is opened in the middle part of the outer peripheral surface of the rotating disk 4 in the axial direction, which is generally 0.3 to 0.5 mm thicker than the thickness of the copper wire. The pressing wheel 2 can press or leave the wire (flat copper strip) put into the axial groove of the rotating disk thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com