Photoelectric torque sensor for vehicle

A technology of torque sensor and photoelectric converter, which is applied in the field of non-contact photoelectric torque sensor and structural design of photoelectric torque sensor, can solve the problems of low precision and difficulty in improving the control level of electric power steering system, and achieve increased Inhomogeneity, ensuring size and shape accuracy, overcoming the effect of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

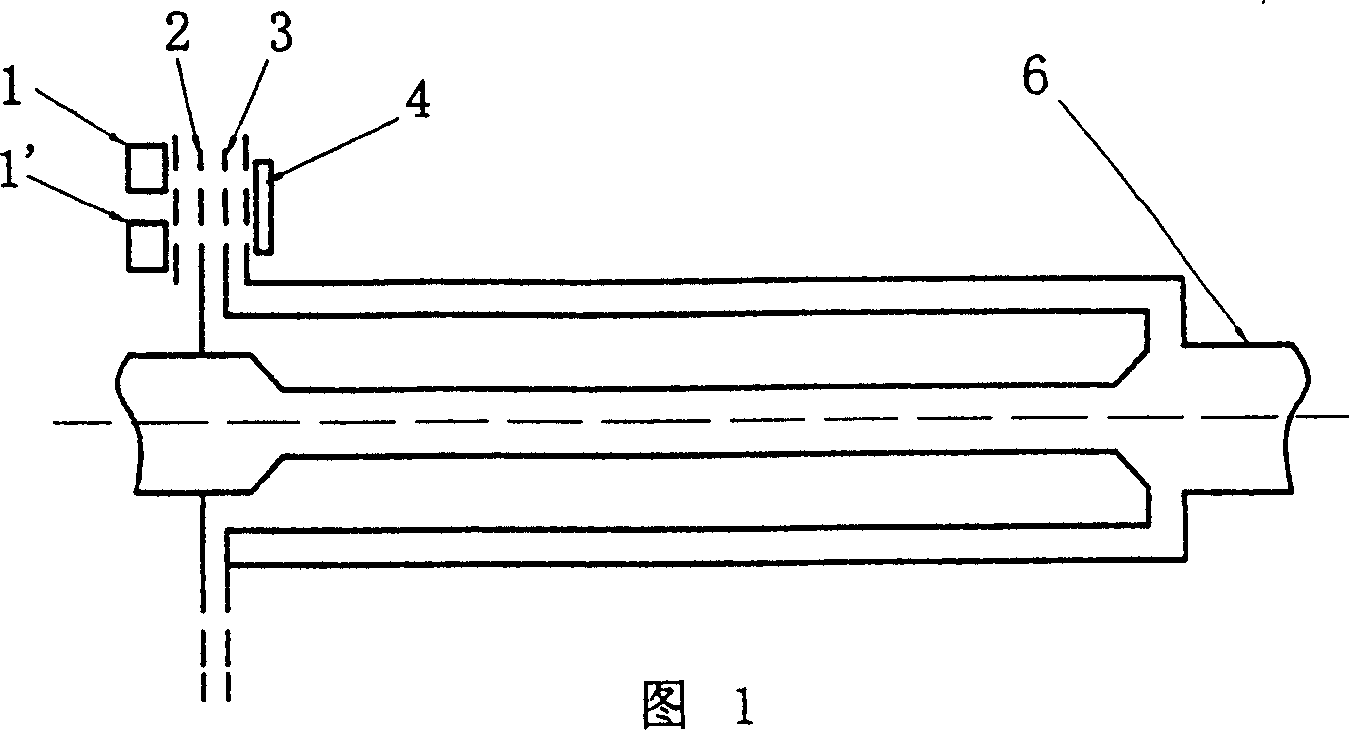

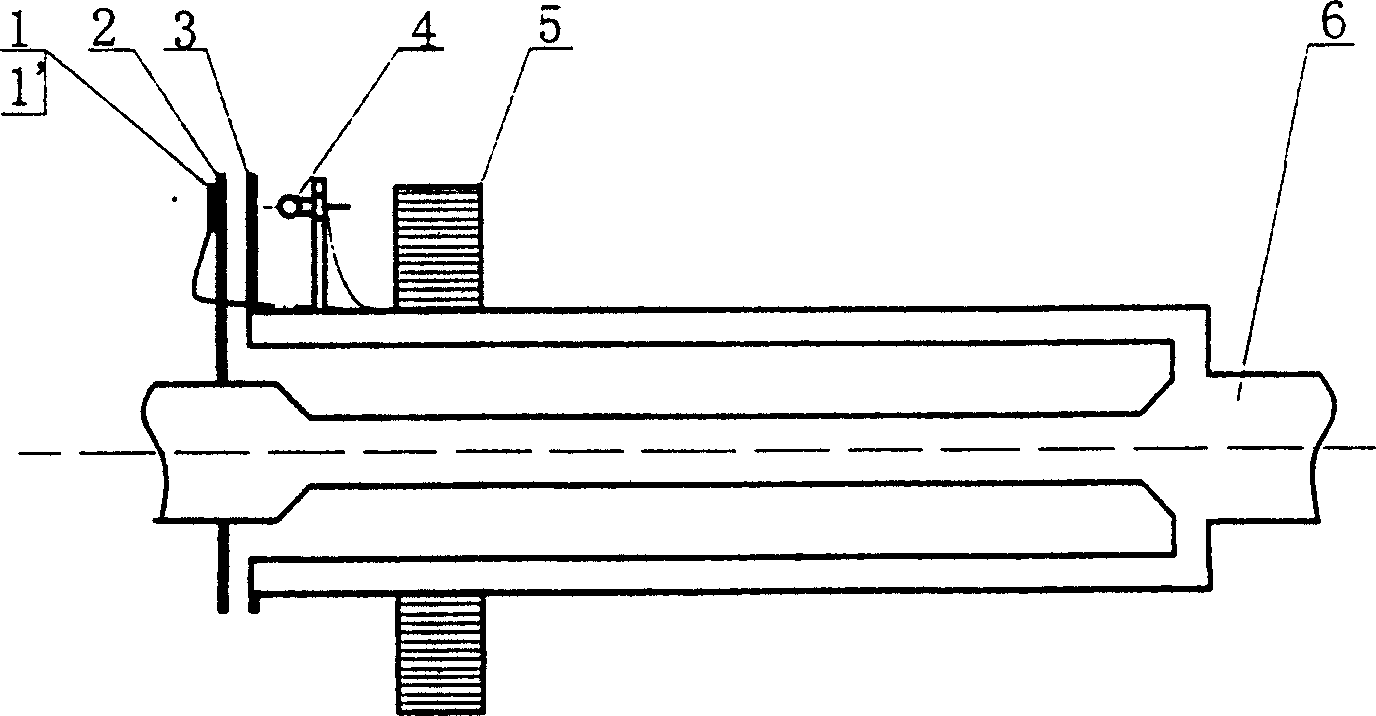

[0050] The present invention designs a photoelectric torque sensor for electric power steering (EPS) system of a car, and the specific structure is as follows: Figure 11 shown.

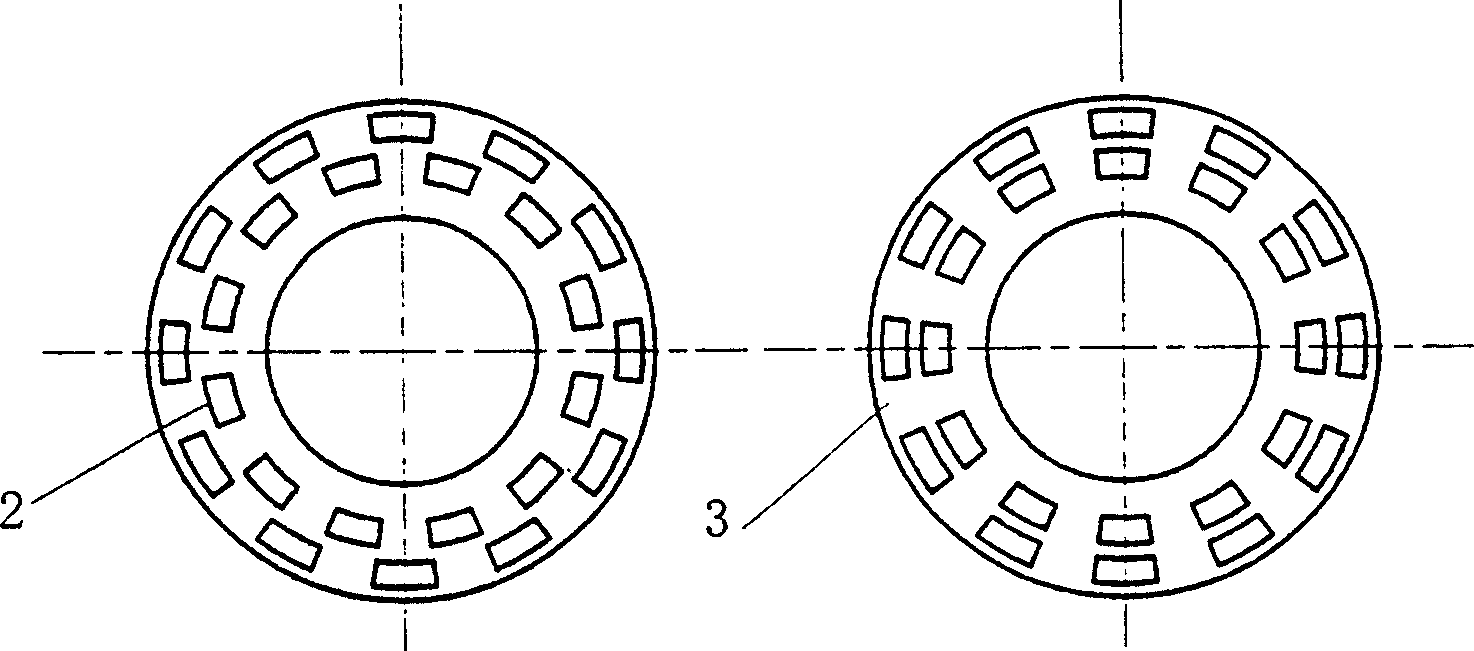

[0051] This embodiment adopts the a'a-type combination method: two photocells 1 and 1' are fixed side by side along the circumferential direction on the outer surface of the light-transmitting hole of the a-type light-transmitting arm 2; the light-emitting diode 4 is aligned with the a'-type The light guide hole of the light blocking arm 3 is fixed on the sleeve 8 . The light-transmitting arm 2 and the light-shielding arm 3 are installed on the inner end of the output shaft 17 and the sleeve 8 respectively, and the outer end of the sleeve 8 is pressed on the inner end of the input shaft 11, and the output shaft 17 is connected with pins 14 and 13 respectively. And the two ends of sleeve 8 and torsion bar 6 are fixed together. The lead of photocell 1 and 1 ' and light-emitting diode 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com