High-voltage DC relay and assembly method thereof

A high-voltage direct current and relay technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as difficulty in ensuring the accuracy of push rod components, sticking or burning of dynamic and static contacts, and difficulty in realizing automatic assembly, etc., to achieve Easy automatic assembly, easy guarantee of dimensional accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

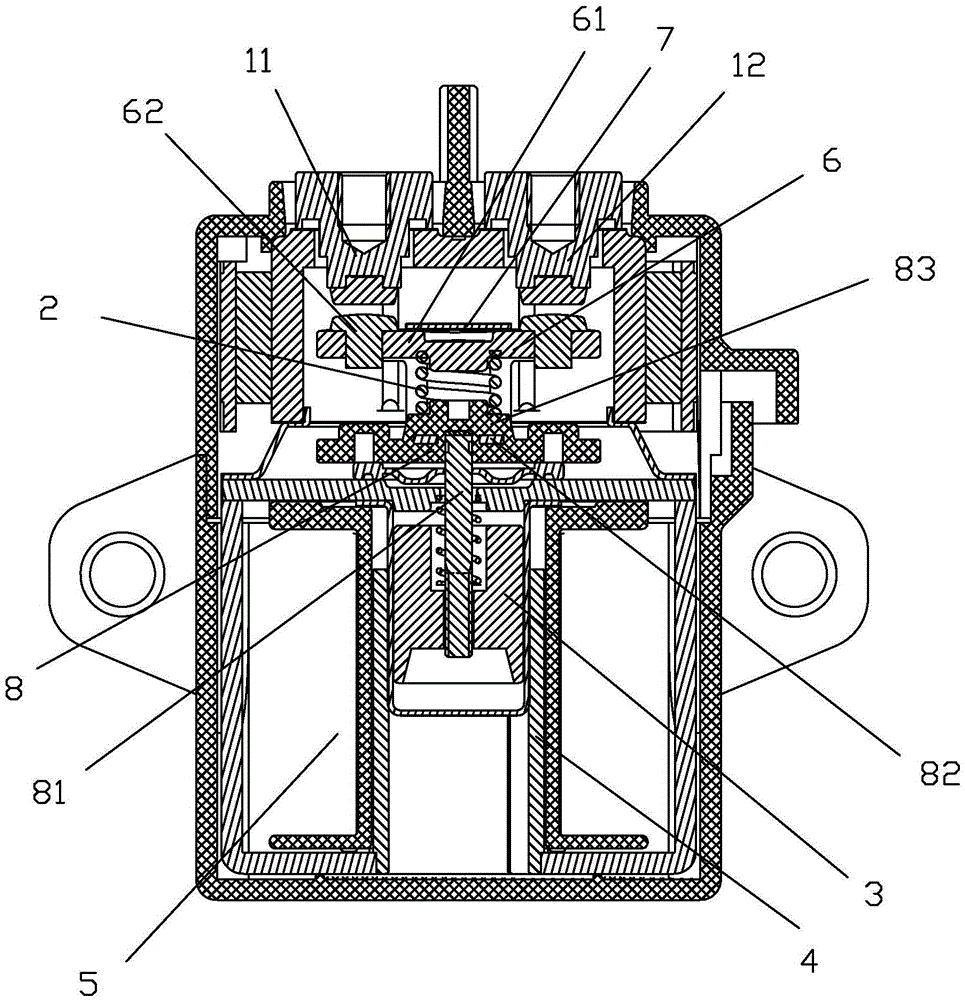

[0051] see Figure 1 to Figure 9 As shown, a high-voltage DC relay of the present invention includes two static contacts 11, 12, a moving assembly, a moving iron core 3, a yoke 4, a coil 5 and other components.

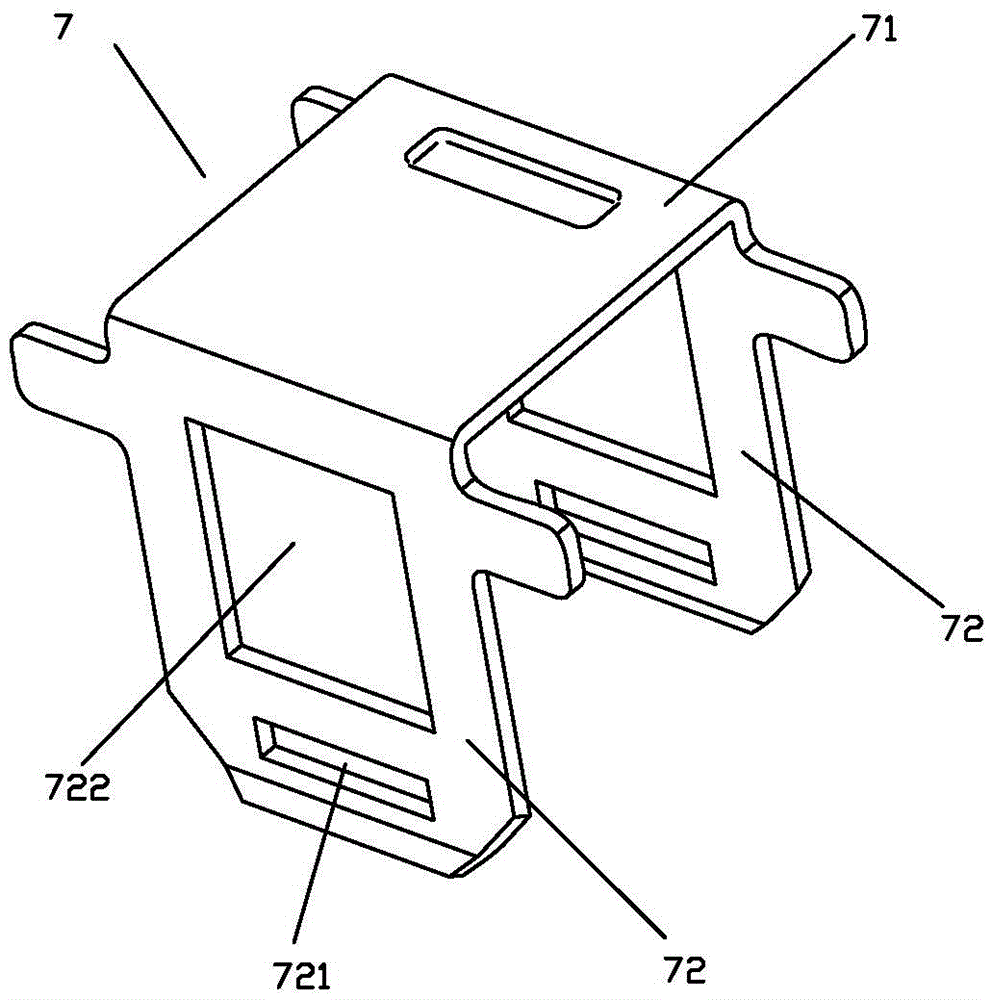

[0052] The moving assembly includes a moving spring part 6, a main spring 2 and a push rod assembly; the moving spring part 6 is made of a moving reed 61 and a moving contact 62 at both ends of the moving reed; the pushing rod assembly consists of a pushing rod The part 8 and the U-shaped basket 7 made of metal materials are composed of two independent parts. The fixed piece 82 and the push rod 81 fixed together by insulating plastic, the fixed piece 82 is also made of metal material, one end of the push rod 81 is connected with the fixed piece 82 through the insulating plastic, and the other end of the push rod 81 is connected with the moving iron core 3 When the moving contacts 62 at both ends of the moving reed 61 are in contact with the static contacts of the two...

Embodiment 2

[0071] see Figure 10 to Figure 11 As shown, a high-voltage direct current relay of the present invention is different from Embodiment 1 in that a second convex bud 712 is also provided on the inner side of the top 71 of the U-shaped basket 7, and the second convex bud 712 It is arranged on the other side corresponding to the width of the moving reed, and the height dimension of the second convex bud 712 is set to have a height difference from the height dimension of the first convex bud 711. In this embodiment, the height dimension of the second convex bud 712 is Greater than the height dimension of the first convex bud 711, so that when the contact is disconnected, the inner side of the top 71 of the U-shaped basket 7 is pressed against the movable reed 61, and the movable reed 61 moves to the other side of the width tilt.

[0072] The second convex bud 712 is formed by bending the corresponding position of the top 71 of the U-shaped basket or punching the bud by using a mo...

Embodiment 3

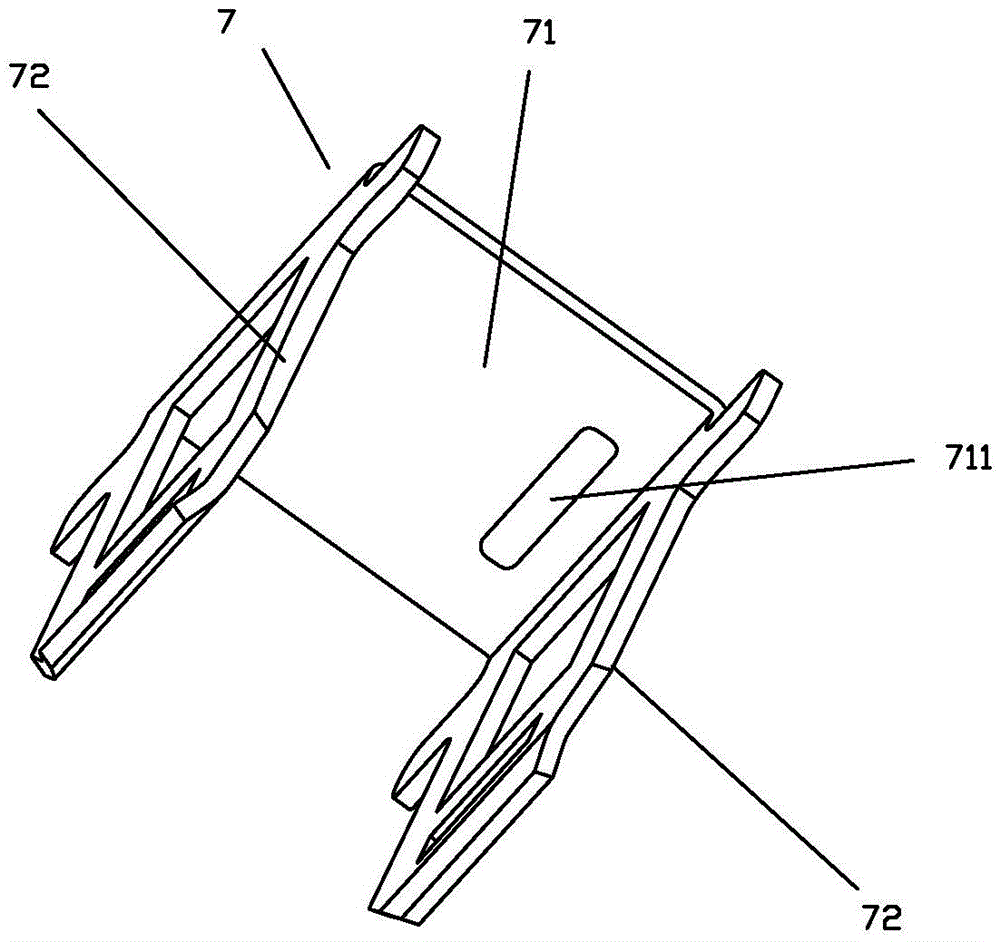

[0074] see Figure 12 to Figure 15 As shown, a kind of high-voltage direct current relay of the present invention is different from Embodiment 1 in that the first convex bud corresponding to the side of the width of the moving reed is not provided on the inner side of the top of the U-shaped basket, but on the inner side of the U-shaped basket. One side corresponding to the length of the movable reed is provided with a third protruding bud 713, and the third protruding bud 713 makes when the contact is disconnected, the third protruding bud 713 on the inner side of the top 71 of the U-shaped basket 7 is connected to the movable reed 61. As a result of the tension, the moving reed 61 is inclined to one side of the length (as Figure 14 , Figure 15 shown).

[0075] The third convex bud 713 is formed by bending the corresponding position of the top 71 of the U-shaped basket or punching the bud by using a mold.

[0076] A kind of high voltage direct current relay of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com