Shaping method of fine diameter cast iron profile material

A technology of small diameter and forming method, applied in welding/cutting medium/material, welding medium, manufacturing tool, etc., can solve the problem of not being able to meet the production needs of small diameter cast iron welding core, and achieve low production cost and strong filling ability. , the effect of eliminating pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

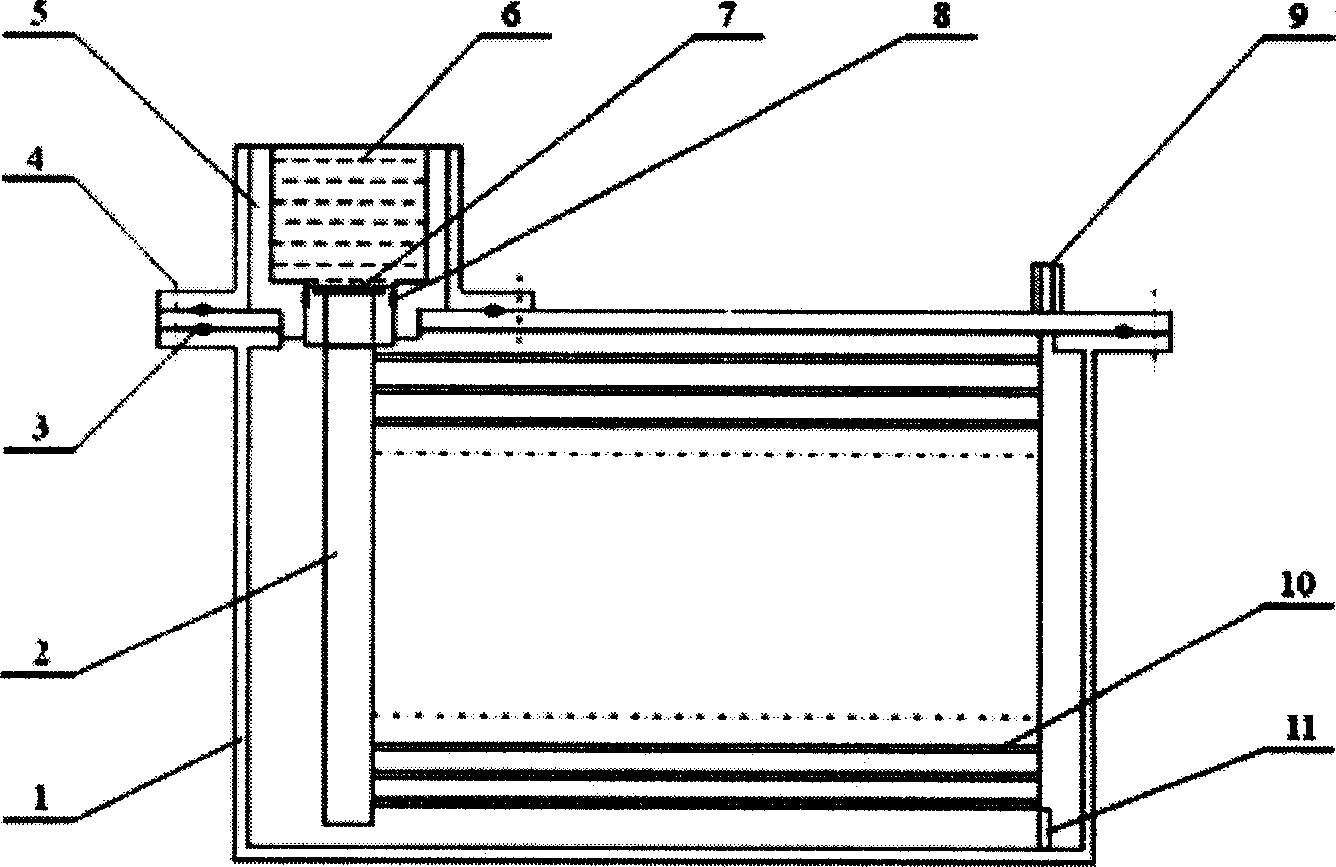

[0019] Oil sand is used to make a mold in which the sprue 2 and the cavity 10 are integrated. After the oil sand mold is dried and hardened, the mold is placed in the vacuum box 1, the sealing cover is sealed, and the sprue basin 5 and the upper cover are tightly sealed, and the top of the sprue 2 is sealed with the sealing mud strip 8 and the plug with the sealing plug 7, and the vacuum pump is turned on through the pumping hole 9, and when the vacuum in the vacuum box 1 reaches 60kPa, the ball The molten iron 6 is poured into the sprue basin 5, and the molten iron 6 of ductile iron enters the cavity 10 through the sprue 2, and is filled, cooled and solidified under the action of vacuum negative pressure to form a ductile iron profile of Φ3mm.

Embodiment 2

[0021] Adopt self-hardening sand to make the casting mold in which the sprue 2 and the cavity 10 are integrated, and the others are the same as in the embodiment 1. When the vacuum in the vacuum box 1 reaches 55kPa, the gray iron molten iron 6 is poured into the sprue basin In step 5, the mold is filled, cooled and solidified under the action of vacuum negative pressure to form a Φ4mm gray cast iron profile.

Embodiment 3

[0023] Adopt self-hardening sand to make the casting mold in which the sprue 2 and the cavity 10 are integrated, and the others are the same as in embodiment 1. When the vacuum in the vacuum box 1 reaches 50kPa, pour the alloy cast iron molten iron 6 into the sprue basin In step 5, the mold is filled, cooled and solidified under the action of vacuum negative pressure to form a Φ10mm alloy cast iron profile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com