Vacuum-induction centrifugal casting device and titanium alloy casting method

A technology for casting titanium alloy and centrifugal casting, which is applied in the field of vacuum induction centrifugal casting equipment, can solve the problems of accelerating the filling speed of liquid metal to the shell, the surface of thin-walled metal castings is defective, and the quality of thin-walled metal castings is reduced, etc. A large amount of heat dissipation, good filling ability, and the effect of shortening the flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

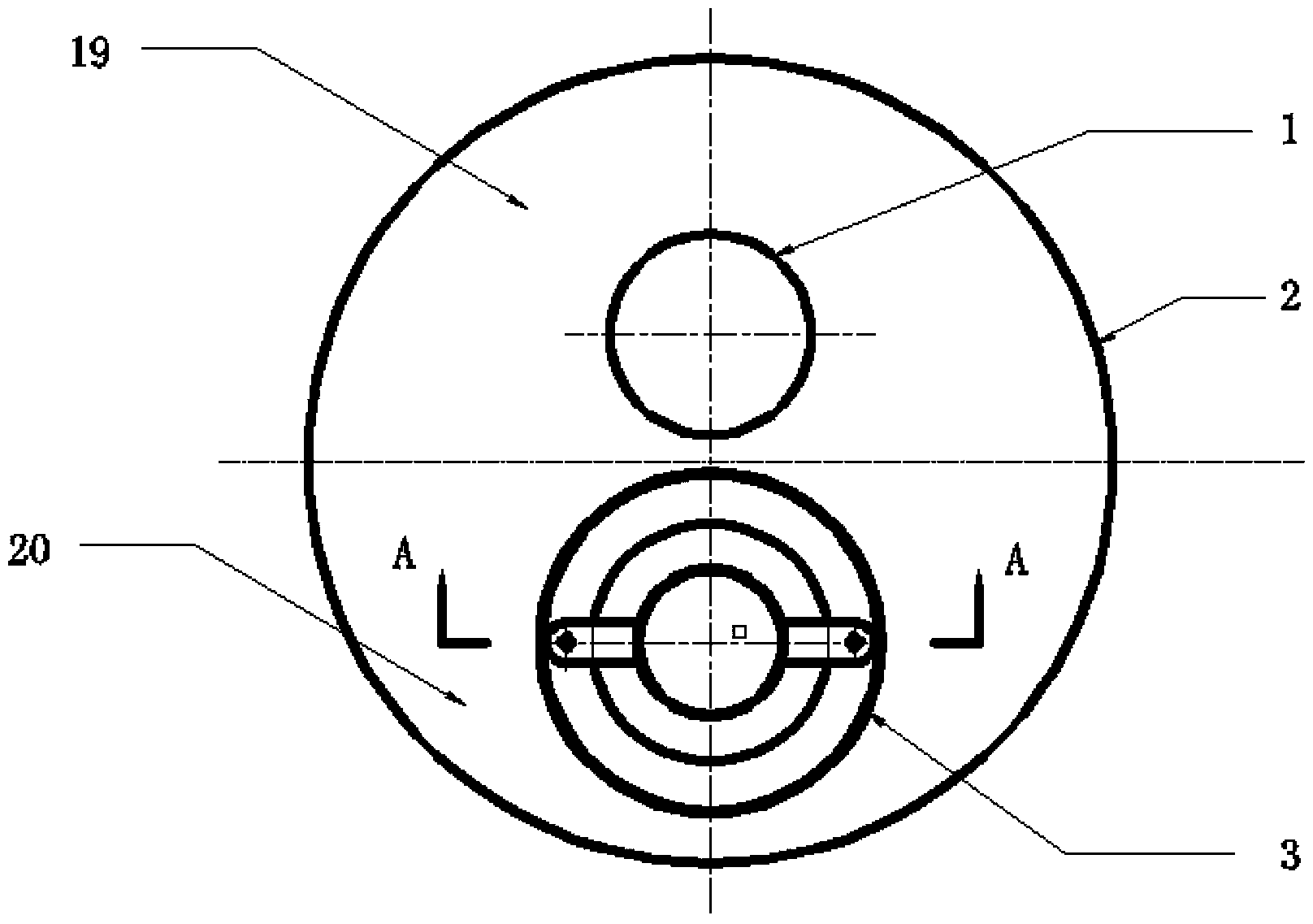

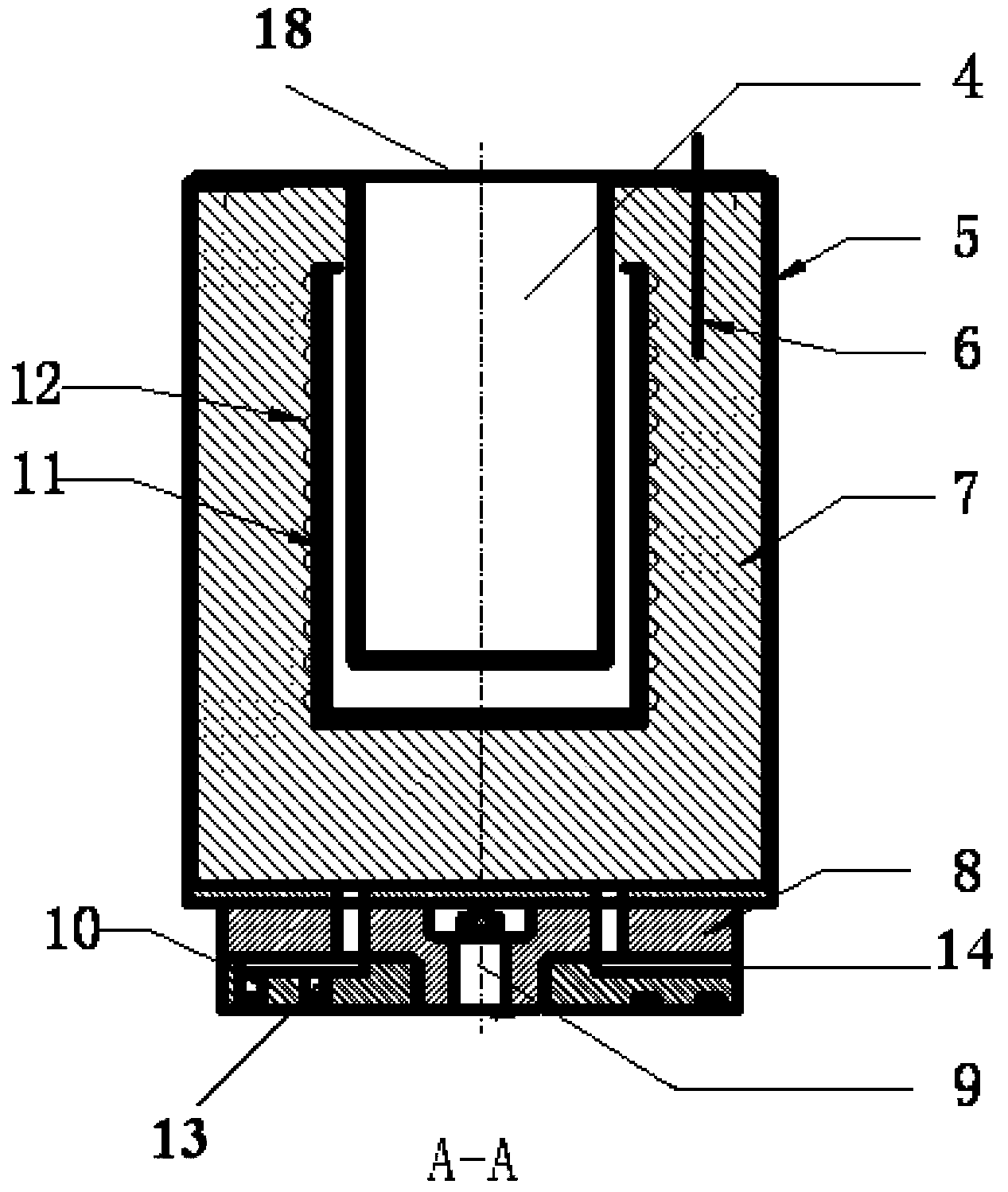

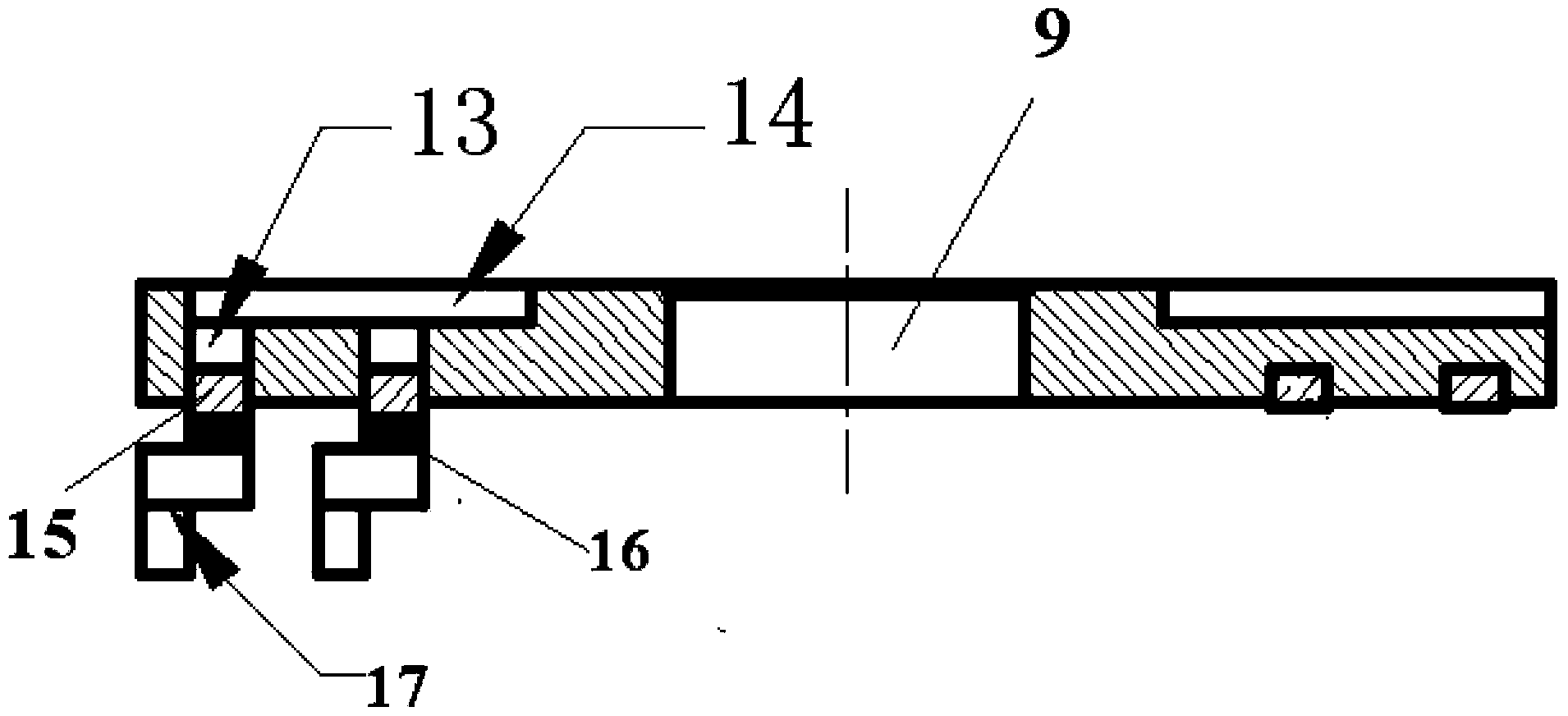

[0041] Vacuum induction centrifugal casting equipment of the present invention, its structure is as figure 1 As shown, there is an equipment casing 2, the upper end of the equipment casing 2 is provided with an upper cover, a melting chamber 19 and a centrifugal casting chamber 20 are symmetrically arranged in the equipment casing 2, a melting device 1 is arranged in the melting chamber 19, and the centrifugal casting Centrifugal heating and pouring device 3 is provided in cavity 20 , and an inversion space for smelting device 1 is provided between the melting chamber 19 and the upper part of centrifugal casting chamber 20 and the upper cover.

[0042] The smelting device 1 includes a crucible and a turning frame. The outer wall of the crucible is provided with an induction coil. The crucible is fixed in the turning frame. The turning frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com