Filling device for filling a container

A technology for filling devices and small containers, which is applied in the field of filling devices and small containers, and can solve problems such as slow filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

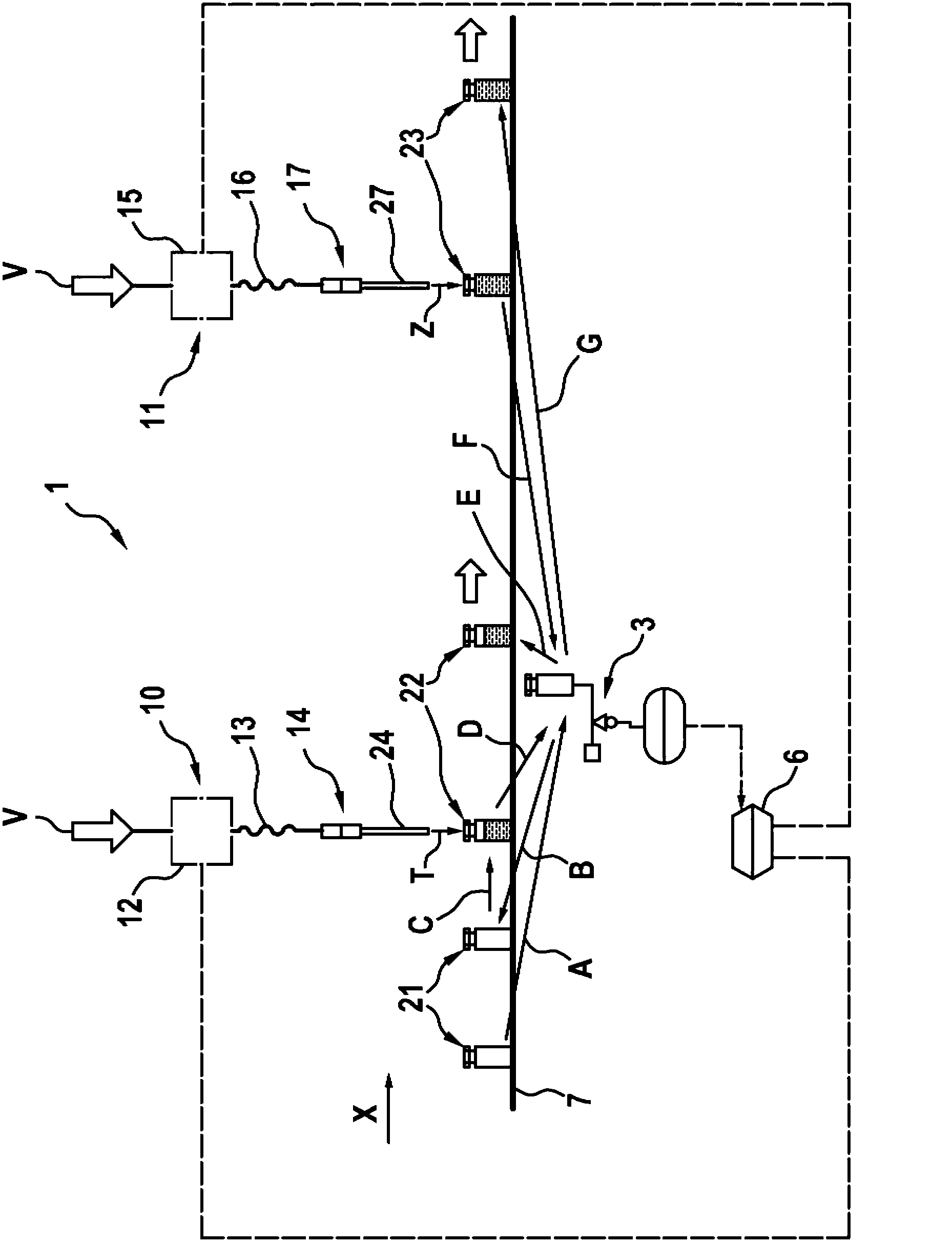

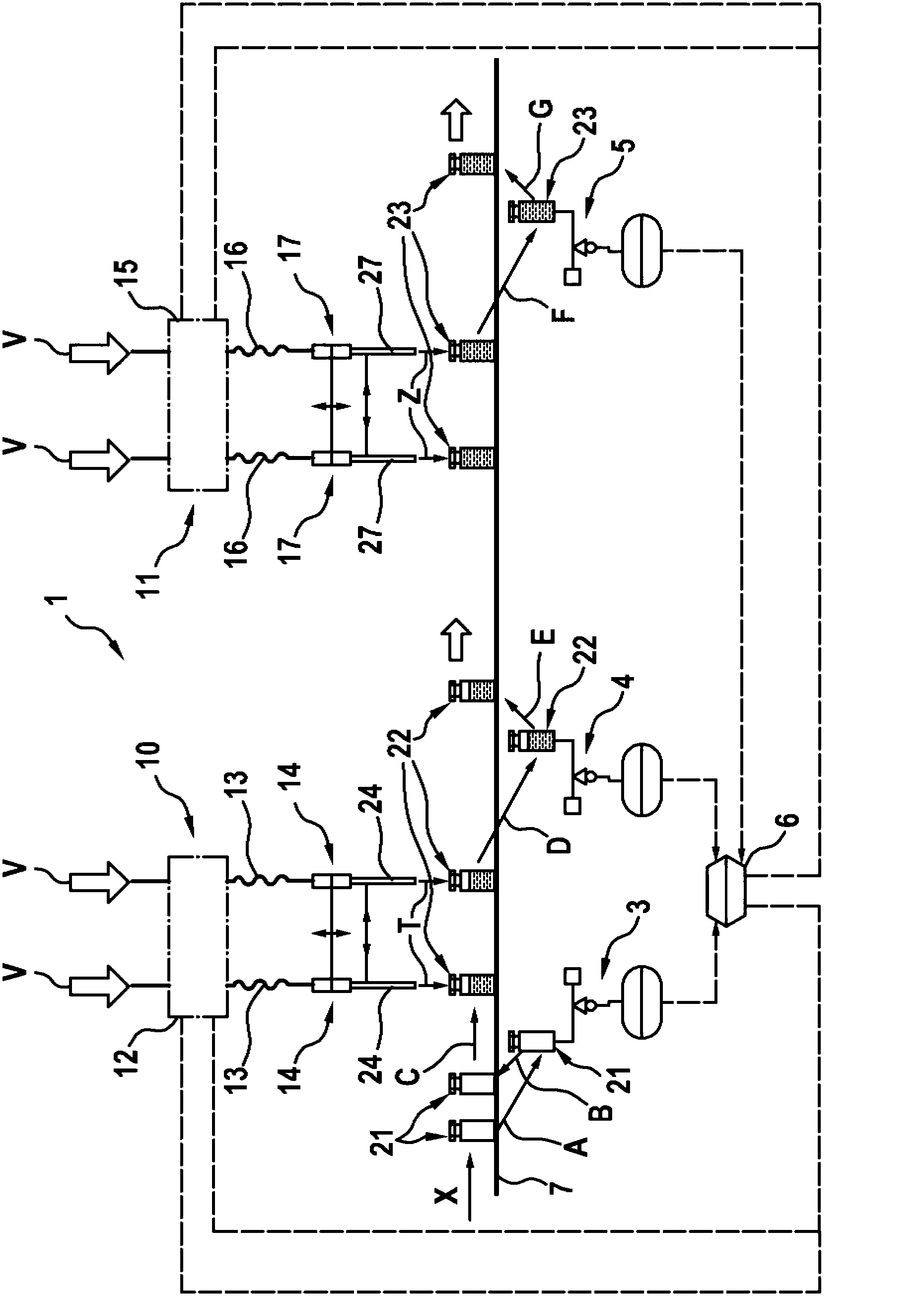

[0018] Refer below figure 1 A filling device 1 according to the invention according to a first exemplary embodiment for filling small containers, in particular with medicinal liquids, is described in detail.

[0019] Such as figure 1 It can be seen that the filling device comprises a first filling unit 10 with a valve 12 , a hose arrangement 13 and a metering device 14 . The valve 12 is connected to a storage container (not shown here), from which the liquid to be filled, as indicated by the arrow V, is fed to the filling unit 10 . Furthermore, a second filling unit 11 is provided, which has a valve 15 , a hose arrangement 16 and a metering device 17 . Like the first filling unit 10 , the liquid to be filled is supplied in the direction of the arrow V to the second filling unit 11 . Furthermore, a conveying device 7 is provided, on which the small containers to be filled are conveyed in the conveying direction indicated by the arrow X to the first and the second filling uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com