A Welding Method for Reducing Electrolyzer Voltage Drop

A welding method and electrolytic cell technology, which is applied in the field of electric power, can solve the problems of general conductive paste effect, insignificant pressure drop effect, deformation of aluminum electrolytic cell, etc., and achieve smooth brazing joints, beautiful appearance, and small deformation of weldments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

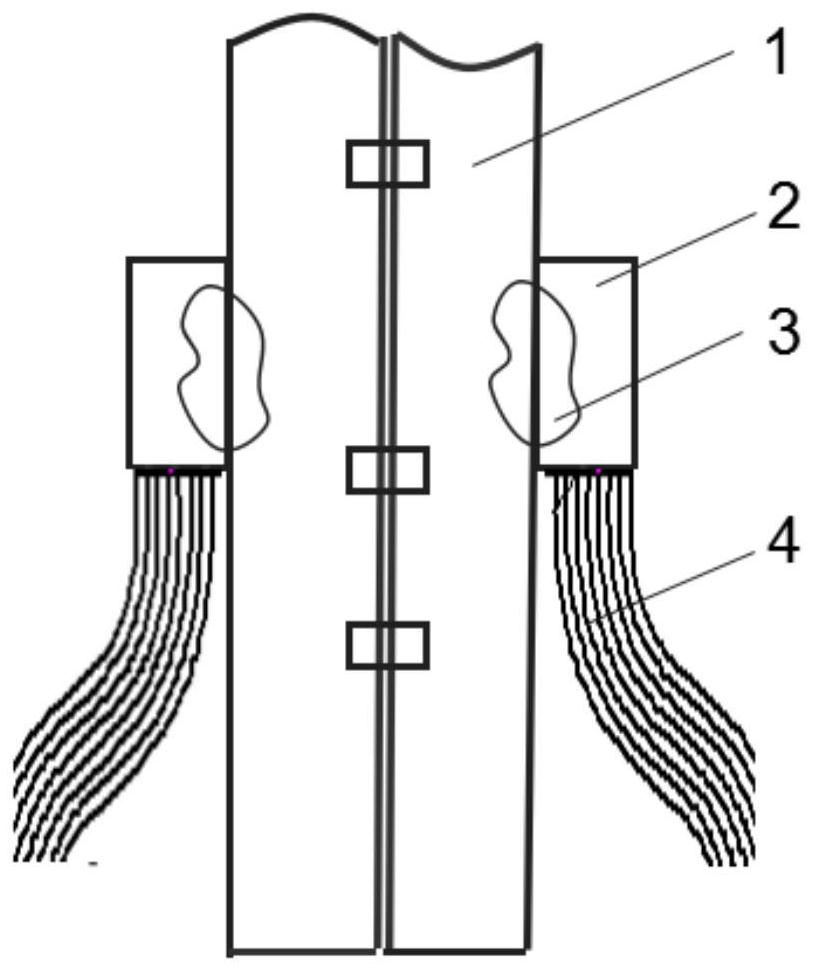

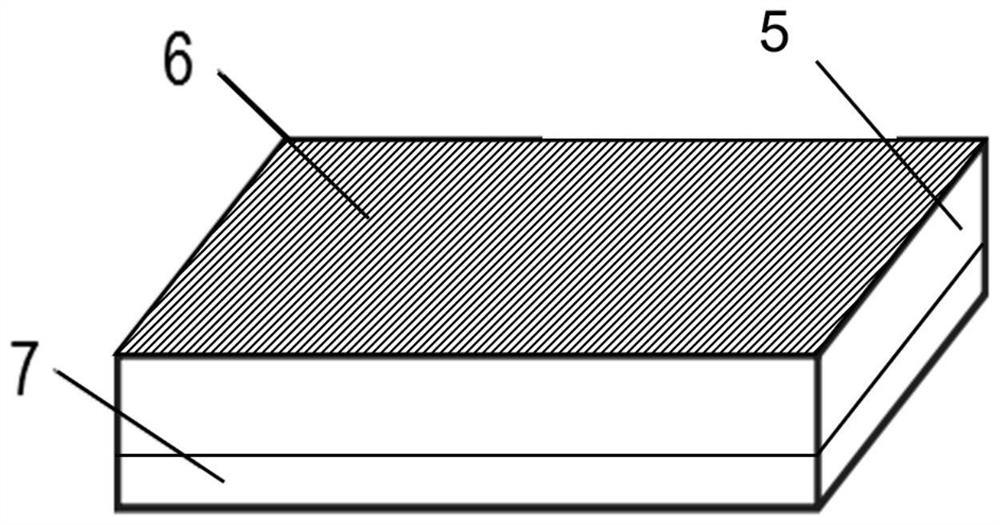

[0027] Grind and clean the surface 3 to be welded at the connection between the upright busbar 1 and the short-circuit busbar 2. Select an aluminum plate 6 with a suitable size, place the aluminum plate 6 horizontally on a thin metal plate 7, and apply a thin layer of rosin on the upper surface of the aluminum plate 6 with a brush. Use the oxyacetylene flame 5 to heat the metal plate 7 so as to achieve the purpose of heating the aluminum plate 6. After the rosin on the surface of the aluminum plate 6 smokes, remove the flame. 0.5% Mn; 7.5% Ag; 1.5% Cu; 15% Zn; Put a thin layer of solder on it. Apply a layer of rosin on the surface of the workpiece to be welded. After confirming that it is correct, use a tool to tighten the aluminum plate 6, closely match the aluminum plate 6 and the surface 3 of the electrolytic tank to be welded and heat it evenly. The heating temperature is 350-450 ° C. 6 Apply a pressure of 5-10MPa. Remove the flame and remove the clamping tool after coo...

Embodiment 2

[0029] Grind and clean the surface 3 to be welded at the connection between the upright busbar 1 and the short-circuit busbar 2. Select an aluminum plate 6 with a suitable size, place the aluminum plate 6 horizontally on a relatively thin metal plate 7, and apply a thin layer of aluminum flux on the upper surface of the aluminum plate 6 with a brush. Use the oxyacetylene flame 5 to heat the metal plate 7 so as to achieve the purpose of heating the aluminum plate 6. After the aluminum flux on the surface of the aluminum plate 6 smokes, remove the flame. 0.2% Mn; 6% Ag; 1.5% Cu; 18% Zn; 0.3% rare earth elements; 47% Sn brazing filler metal to gently scrape the upper surface of the aluminum plate 6, so that the aluminum plate 6 is evenly coated Put a thin layer of solder on it. Apply a layer of aluminum flux on the surface of the workpiece to be welded. After confirming that it is correct, use a tool to tighten the aluminum plate 6, closely match the aluminum plate 6 and the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com