Patents

Literature

41results about How to "Large thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

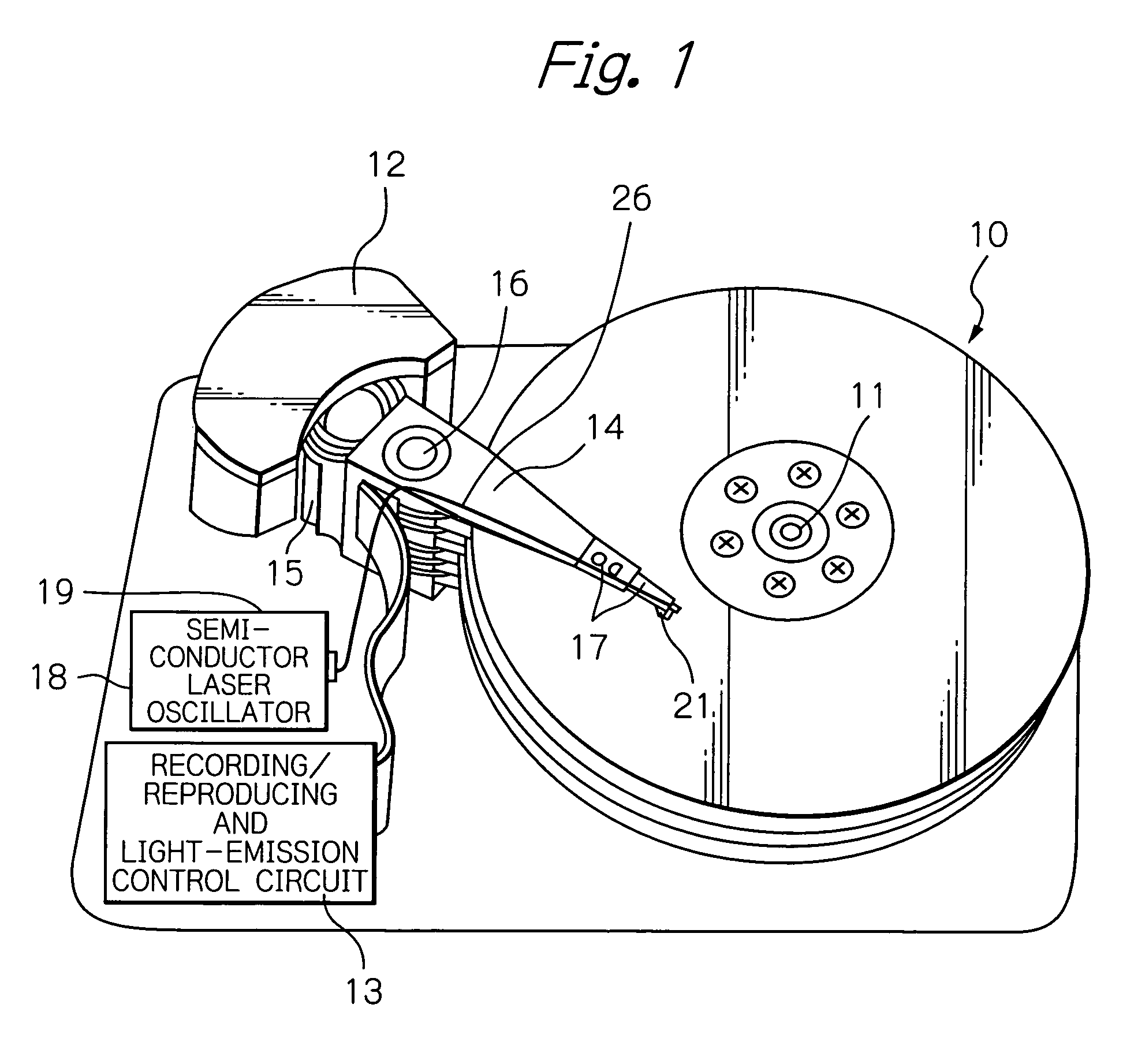

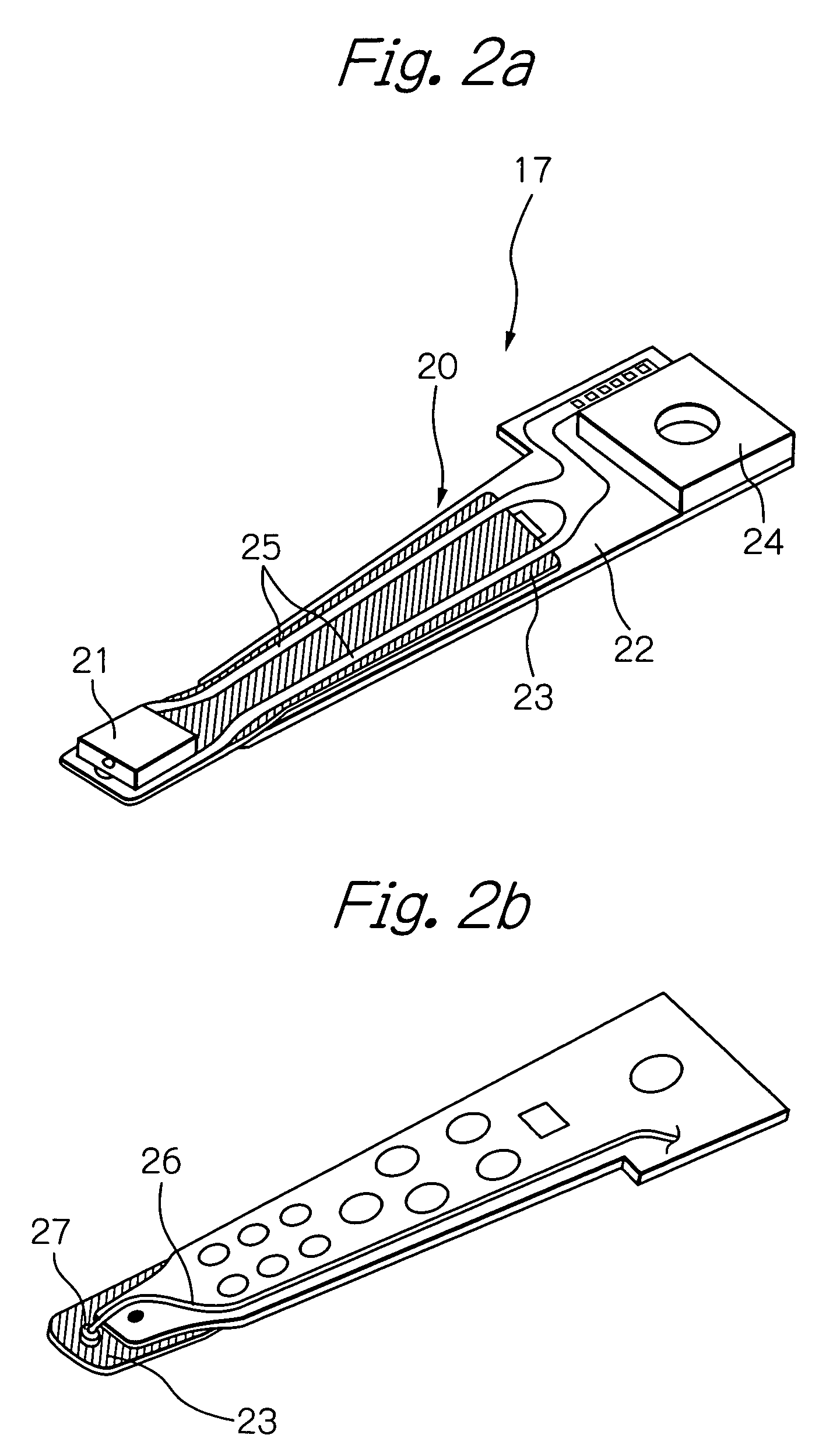

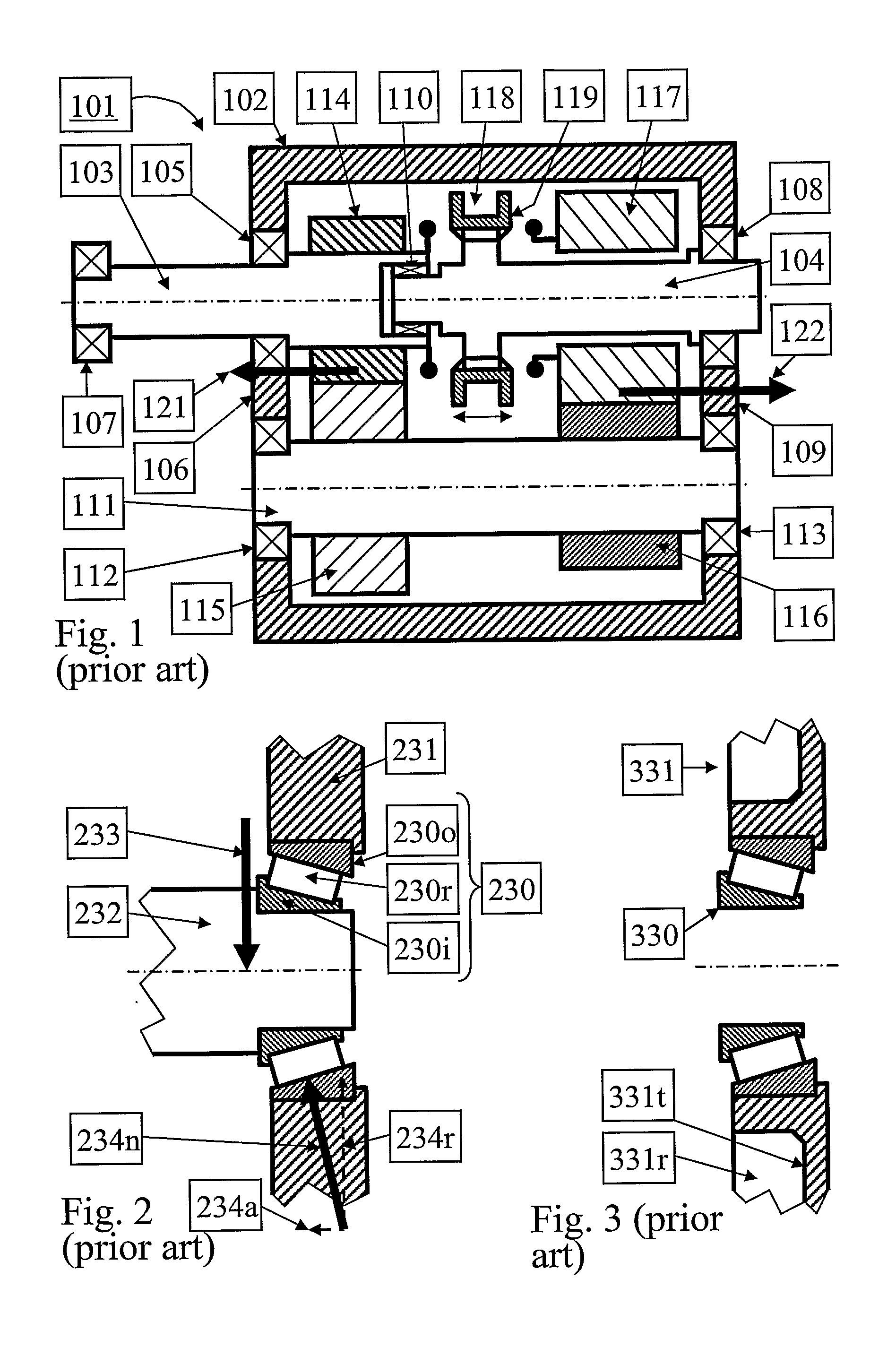

Thin-film magnetic head with near-field-light-generating layer

ActiveUS20070139818A1Improve reliabilityLow coercivityCombination recordingArm with optical waveguideMagnetic mediaBiomedical engineering

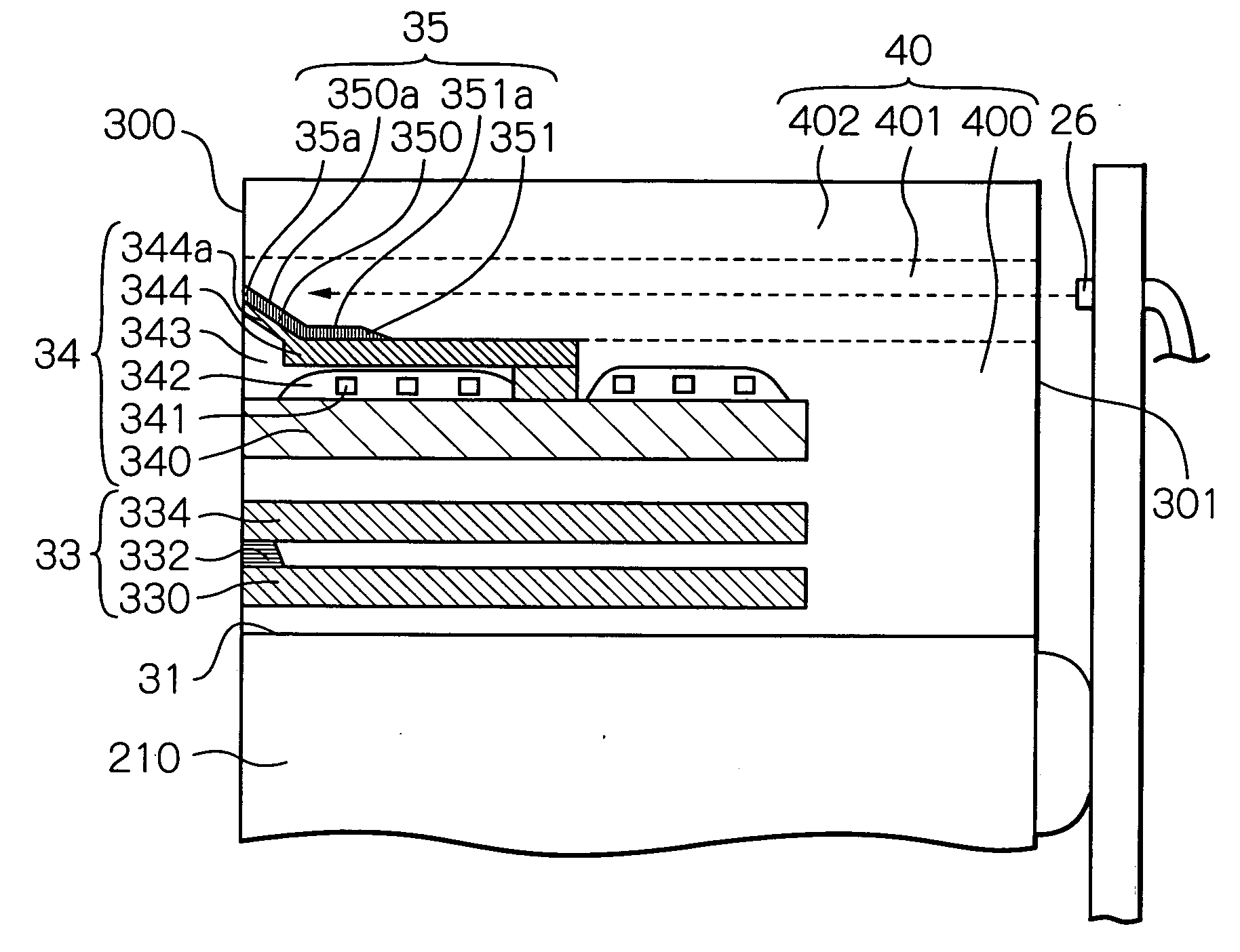

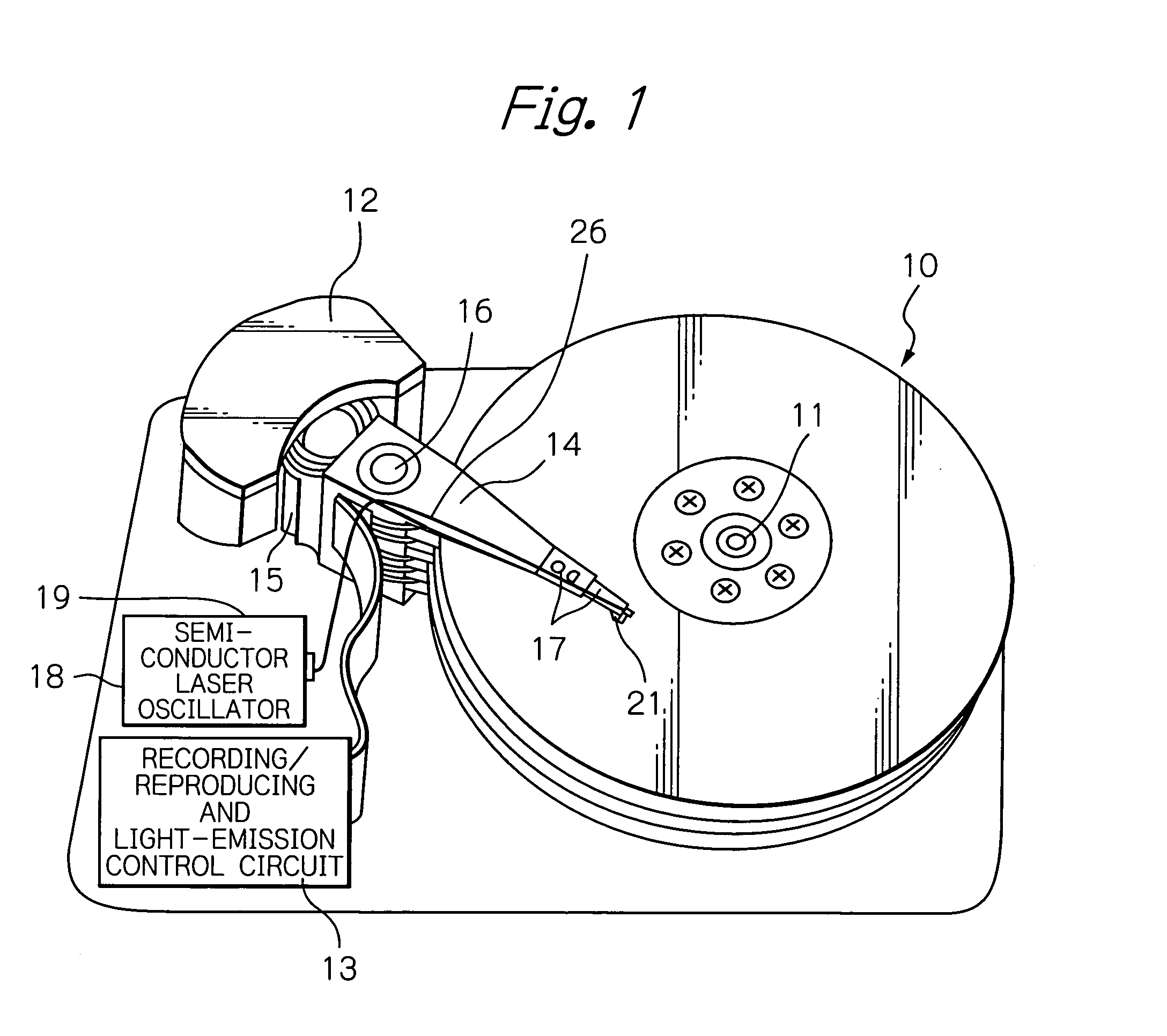

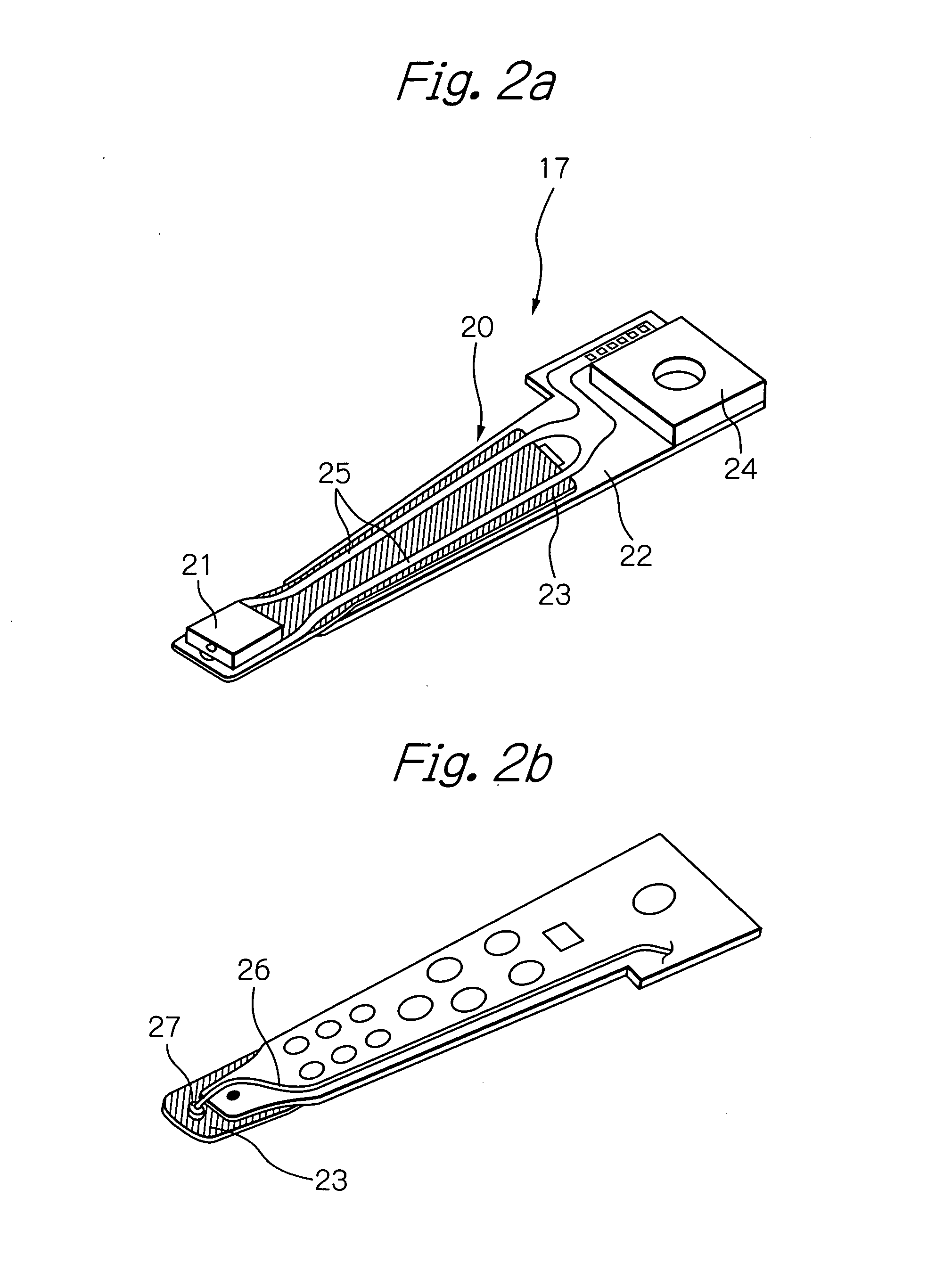

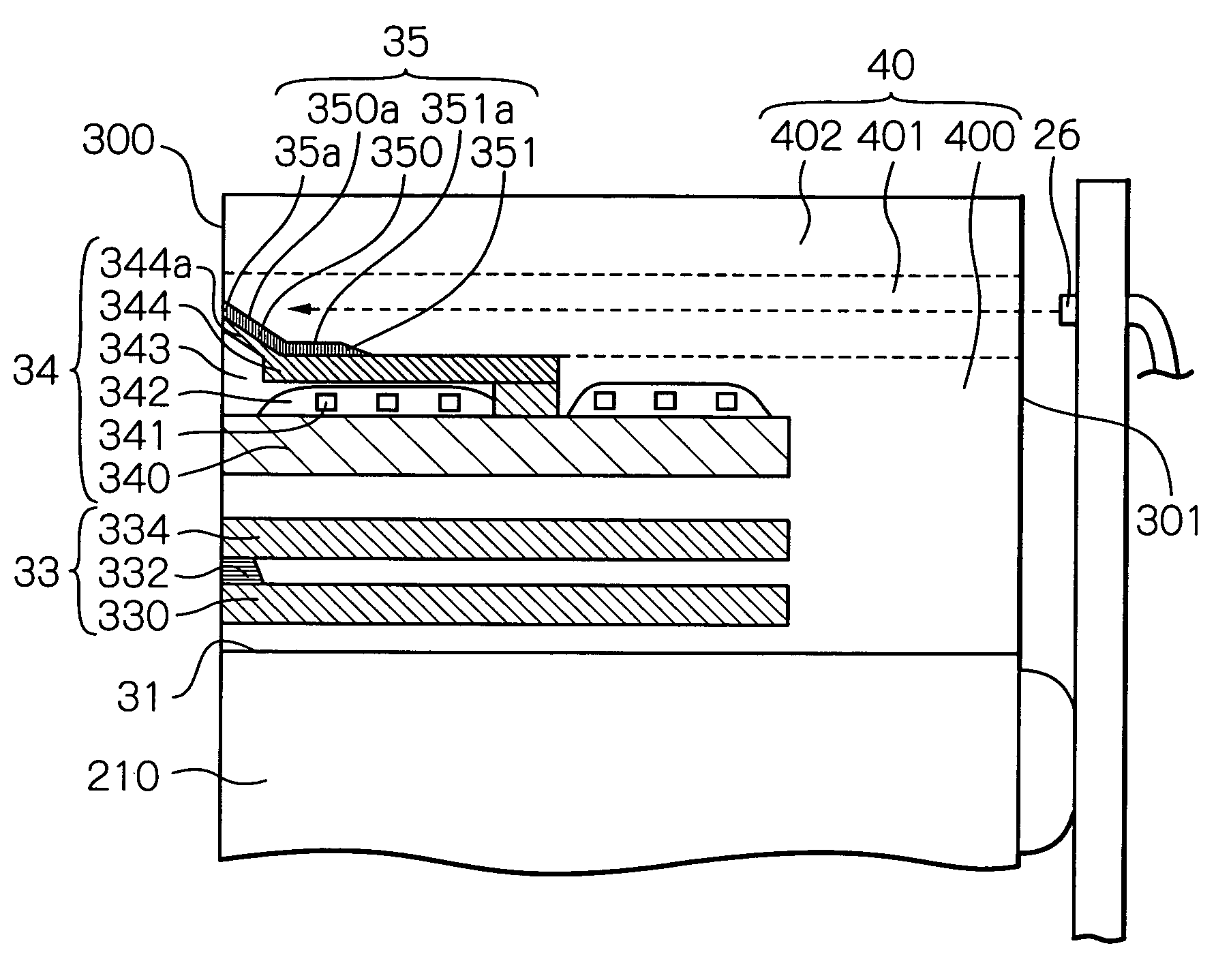

A thin-film magnetic head that has a configuration in which the element-formed surface and the opposed-to-medium surface are perpendicular to each other, and a light source is sufficiently distanced from the medium surface is provided. The head comprises at least one near-field-light-generating layer for heating a part of a magnetic medium during write operation by generating a near-field light, having a shape tapered toward a head end surface on the opposed-to-medium surface side, and comprising a near-field-light-generating portion having a light-received surface and a tip reaching the head end surface on the opposed-to-medium surface side, and the light-received surface being sloped in respect to the element-formed surface and being provided in a position where an incident light propagating from a head end surface opposite to the opposed-to-medium surface can reach at least a part of the light-received surface.

Owner:TDK CORPARATION

Thin-film magnetic head with near-field-light-generating layer

ActiveUS7911882B2Improve reliabilityLow coercivityRecording by magnetic meansArm with optical waveguideMagnetic mediaEngineering

A thin-film magnetic head that has a configuration in which the element-formed surface and the opposed-to-medium surface are perpendicular to each other, and a light source is sufficiently distanced from the medium surface is provided. The head comprises at least one near-field-light-generating layer for heating a part of a magnetic medium during write operation by generating a near-field light, having a shape tapered toward a head end surface on the opposed-to-medium surface side, and comprising a near-field-light-generating portion having a light-received surface and a tip reaching the head end surface on the opposed-to-medium surface side, and the light-received surface being sloped in respect to the element-formed surface and being provided in a position where an incident light propagating from a head end surface opposite to the opposed-to-medium surface can reach at least a part of the light-received surface.

Owner:TDK CORPARATION

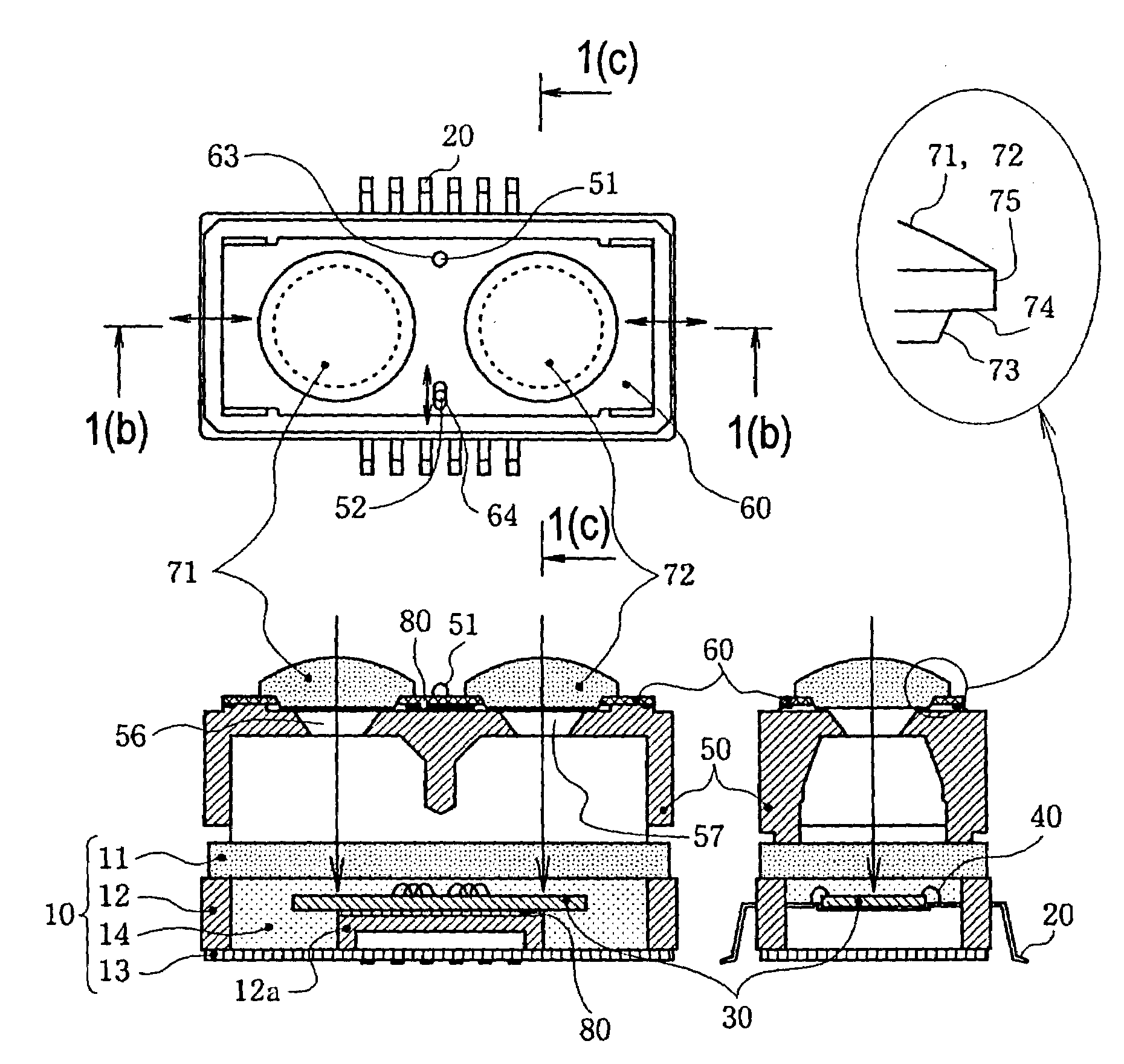

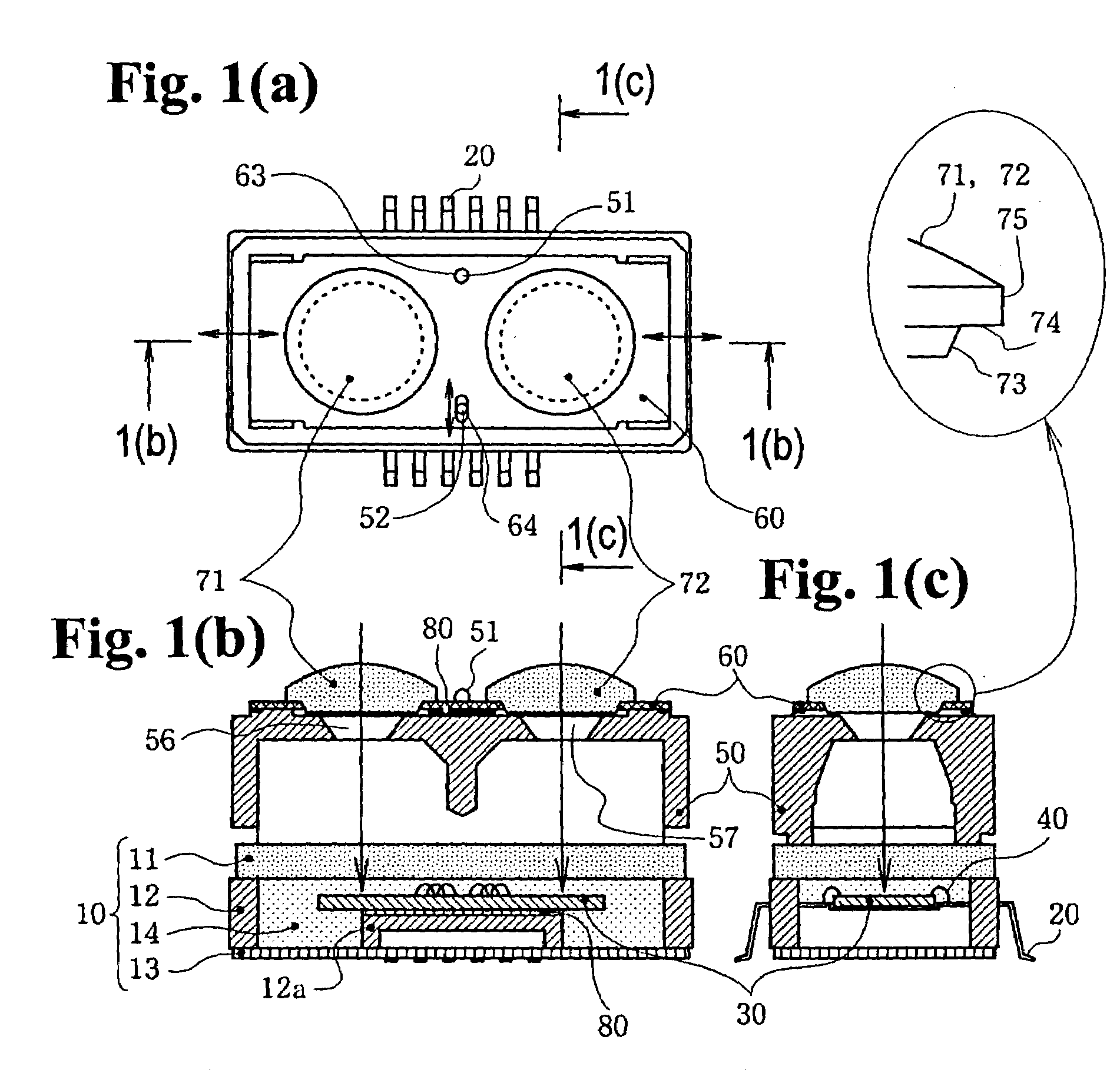

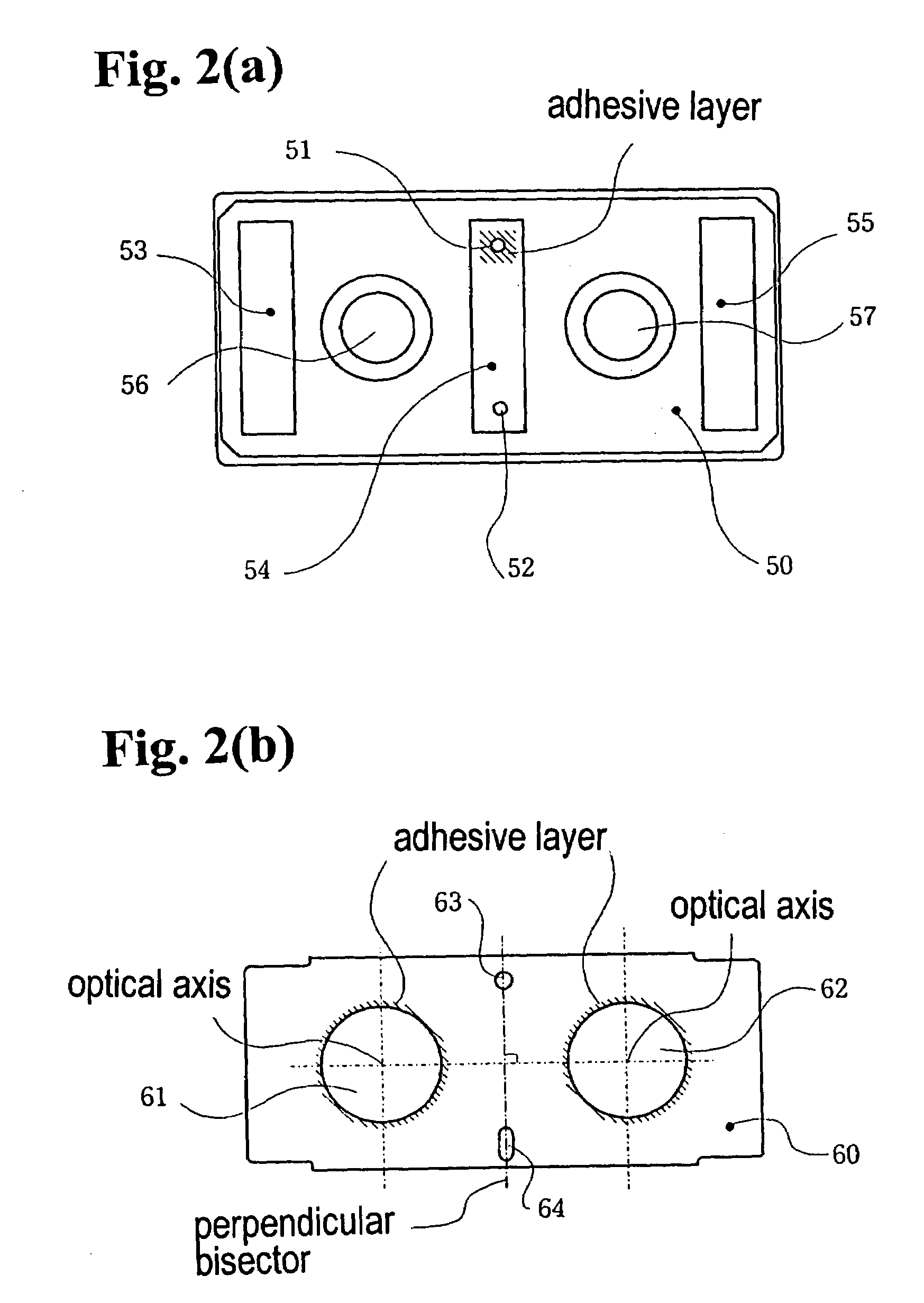

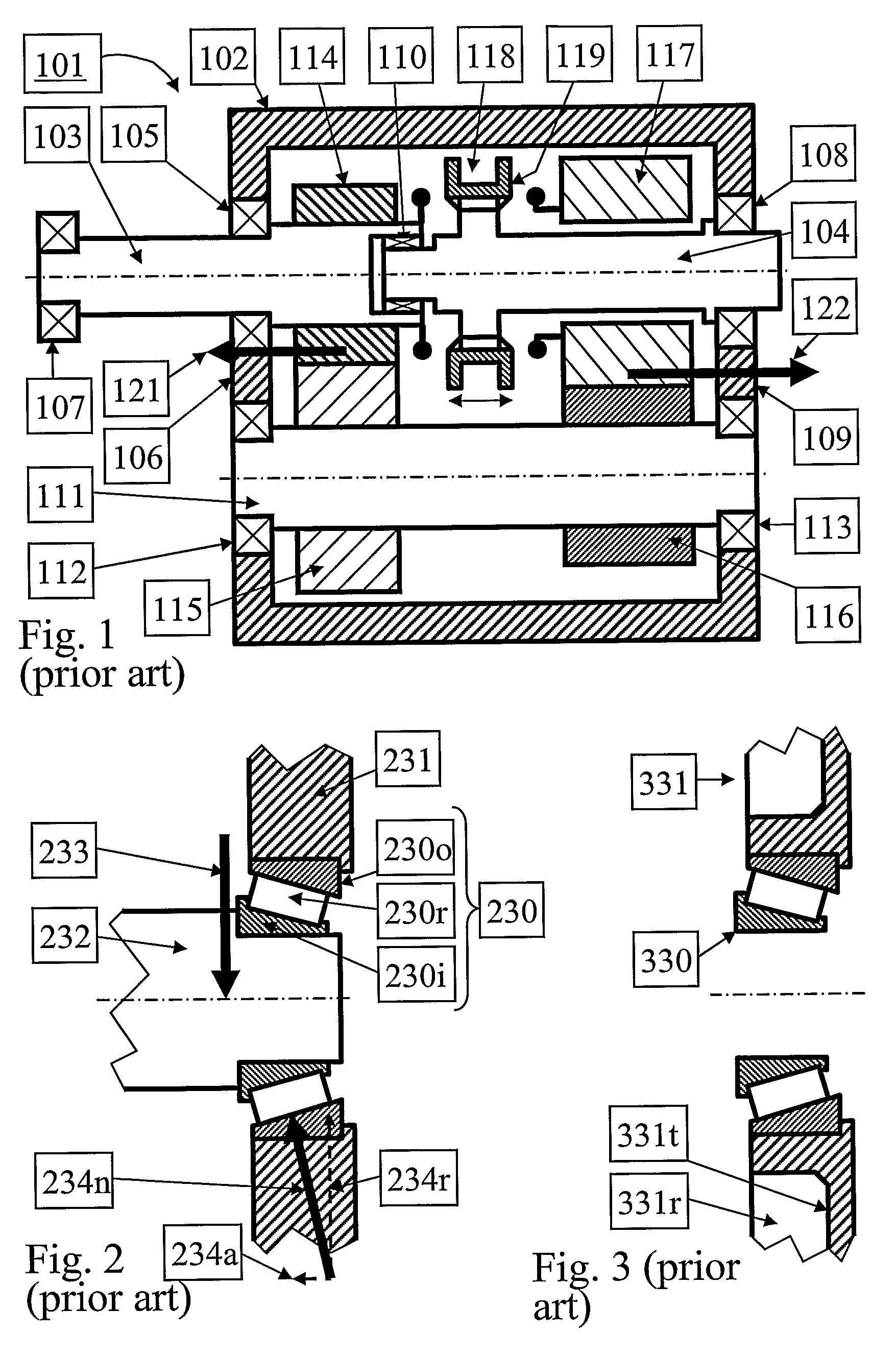

Range finder

InactiveUS7046344B2Reduce the impactReduce contractionOptical rangefindersHeight/levelling measurementSemiconductor chipThermal expansion

A range finder includes a package, a semiconductor chip, an optical casing, a lens holder, a first lens, and a second lens. The first and second lenses are attached to the lens holder. The lens holder is formed of a material having a thermal expansion coefficient equal or close to that of the semiconductor chip. The range finder is constructed such that a distance between the two lenses and a distance between two light detecting sections on the semiconductor chip do not change significantly relative to each other due to the thermal expansion or contraction.

Owner:FUJI ELECTRIC DEVICE TECH CO

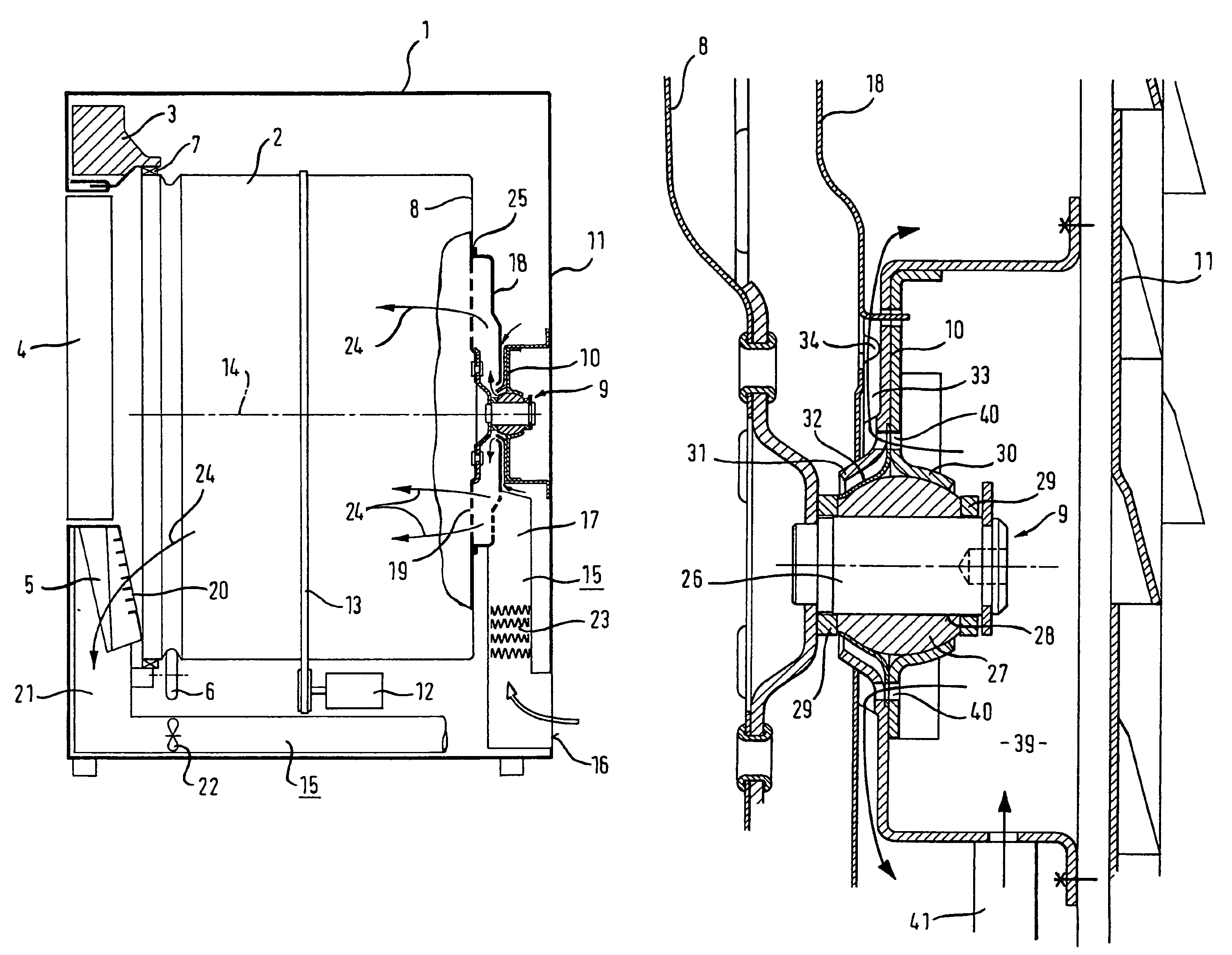

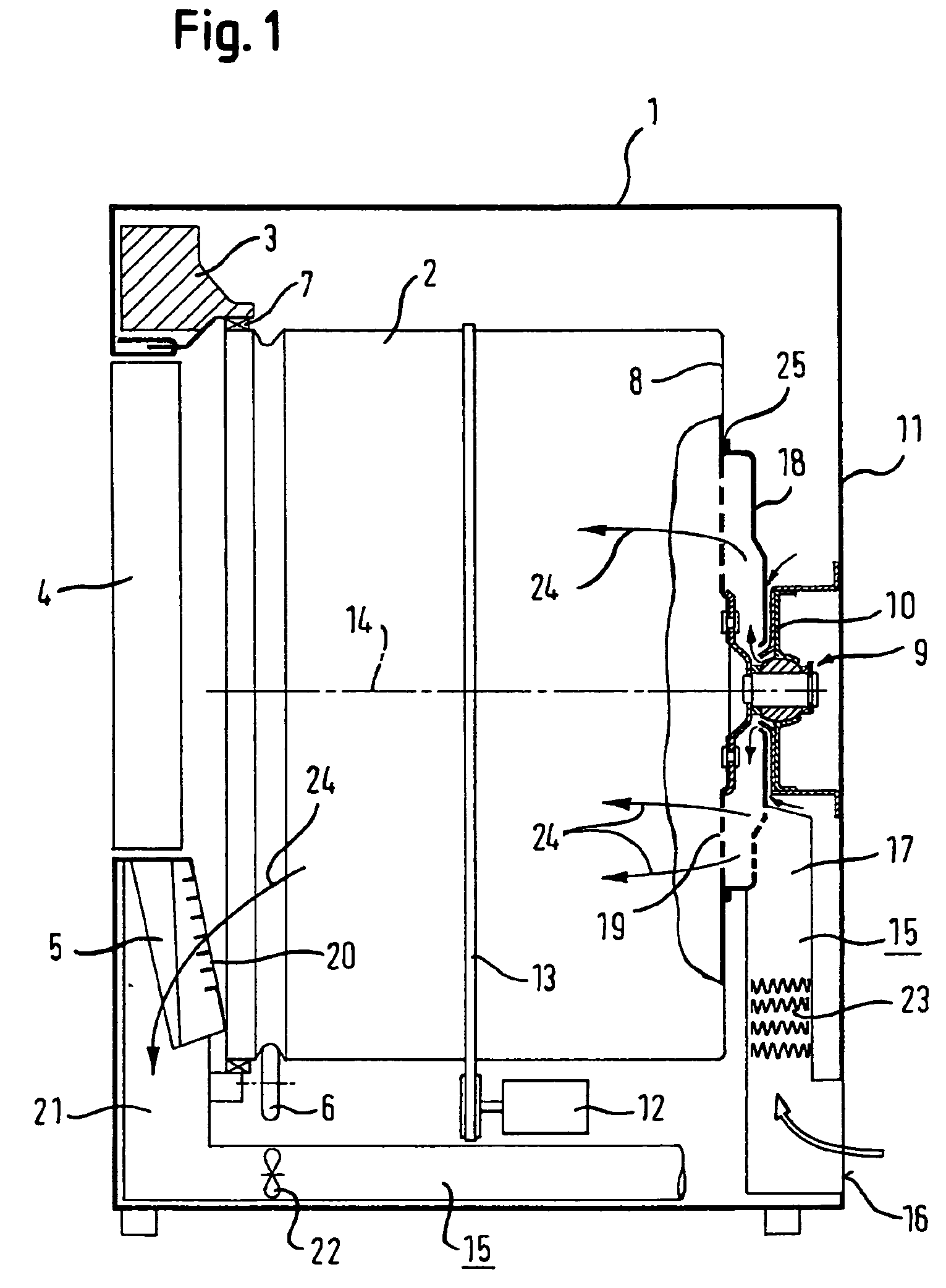

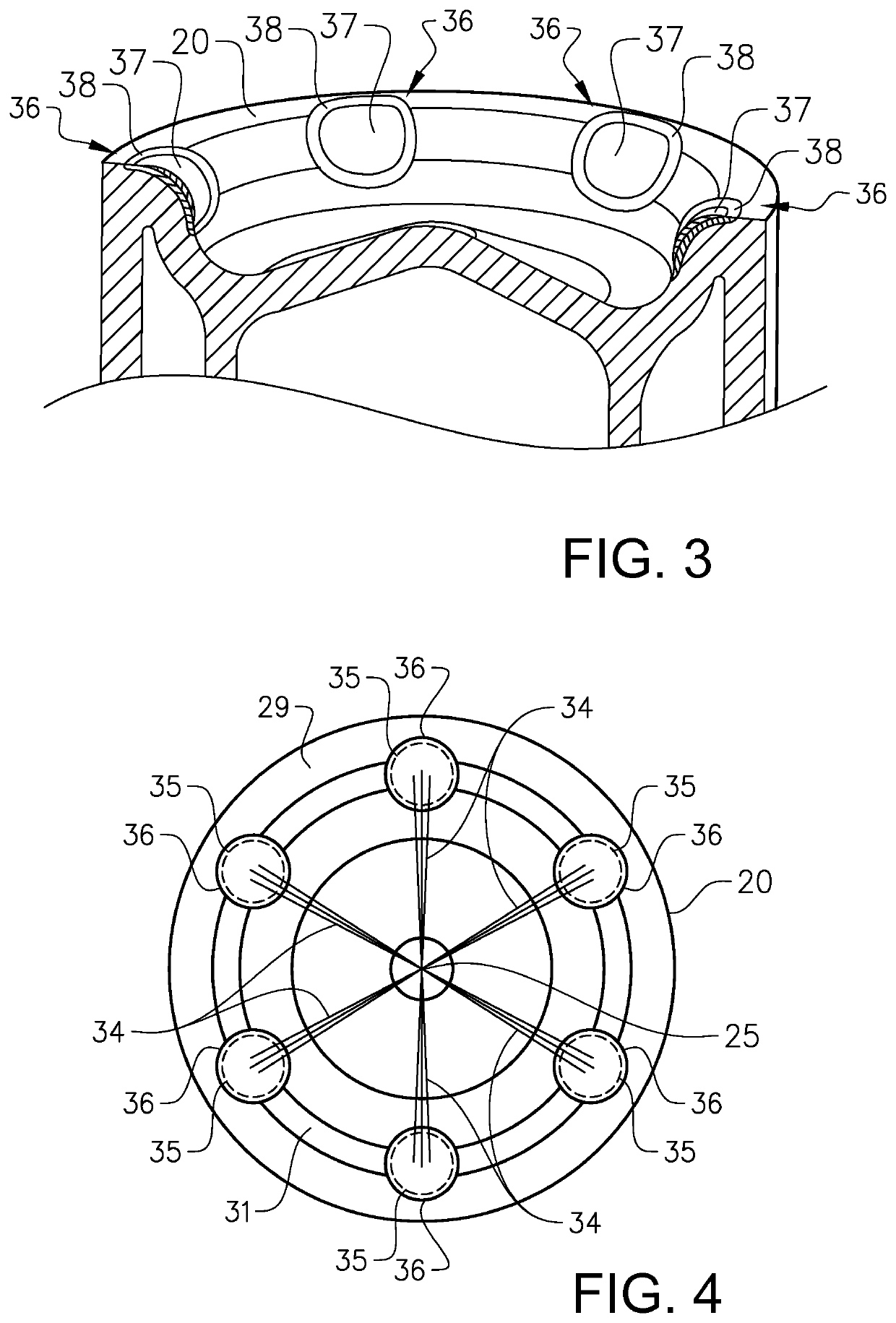

Clothes dryer

InactiveUS7644514B2Reduce loadImprove life and reliabilityRolling contact bearingsTextile treatmentMechanical engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

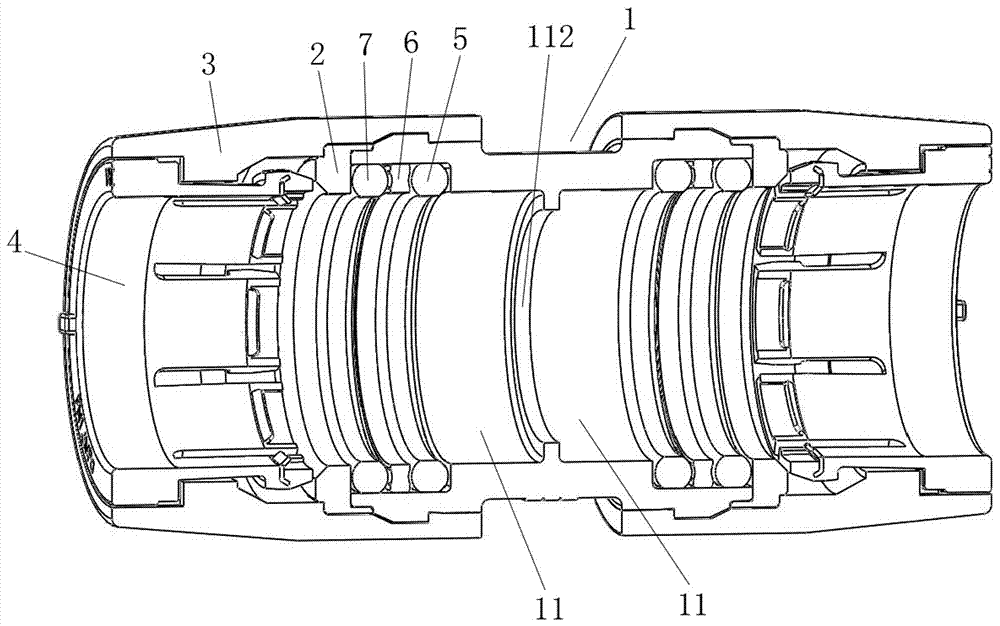

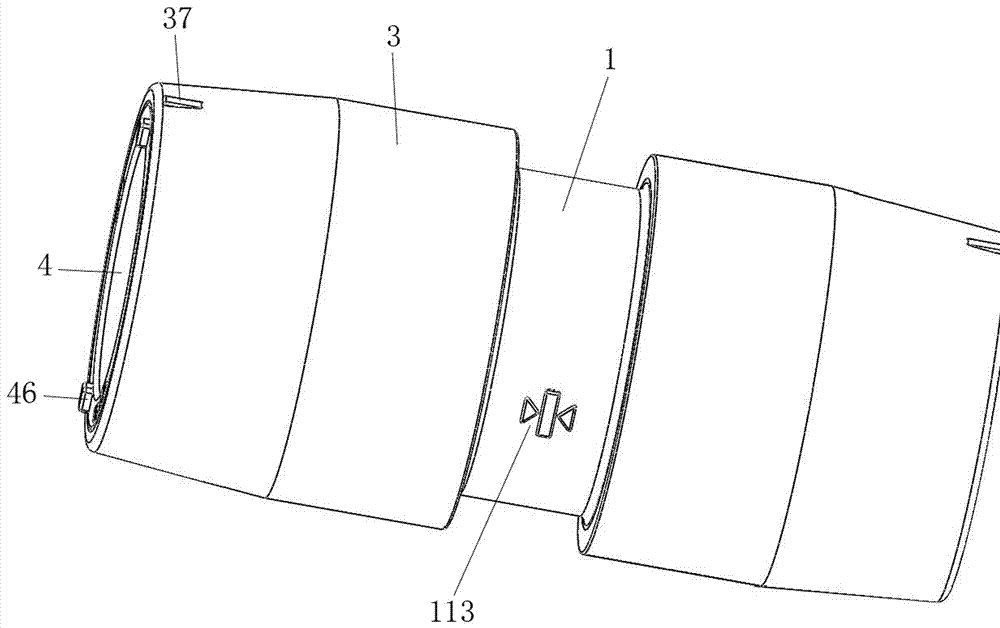

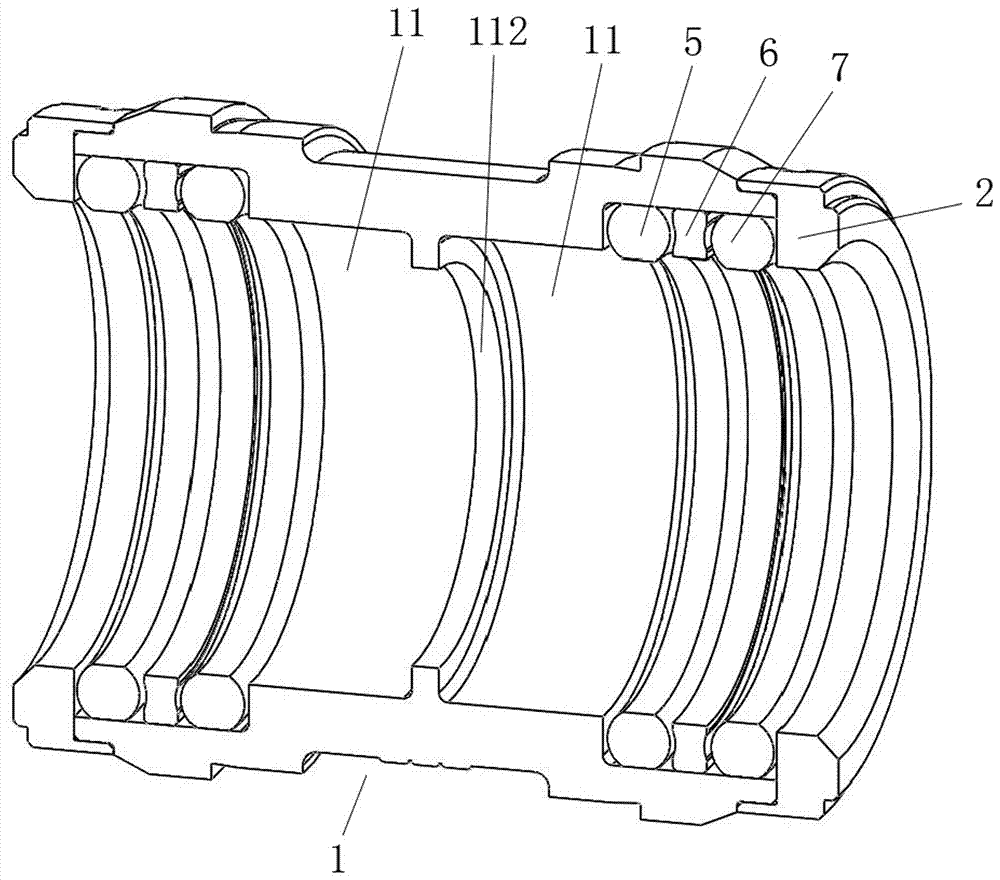

Rapid type pipeline connector

ActiveCN106979427ALarge thermal expansionSoft materialCouplingsPipe fittingElectrical and Electronics engineering

The invention discloses a rapid type pipeline connector. The rapid type pipeline connector comprises a pipeline connector, one or more rapid type connecting ports used for external connecting pipelines are formed in the pipeline connector, the inner wall of each rapid type connecting port is provided with a circle of connecting groove communicating to the end surface of the rapid type connecting port, and a sealing assembly is placed in each connecting groove. Each rapid type connecting port is sleeved with a rapid connecting assembly, and each rapid connecting assembly comprises a rapid connecting inner annular cover, an outer cylinder cover and a receding stopping sleeve, wherein the rapid connecting inner annular cover sleeves the corresponding connecting port and blocks the outside of the sealing assembly, the outer cylinder cover sleeves the corresponding rapid connecting inner annular cover and the corresponding connecting port, and the receding stopping sleeve is mounted in the corresponding outer cylinder cover and located at the outside of the corresponding rapid connecting annular cover. The external connecting pipelines can penetrate through the receding stopping sleeves and the rapid connecting inner annular covers to be inserted into the sealing assemblies in the connecting ports. According to the rapid type pipeline connector, rapid mounting and dismounting operation of the external connecting pipelines can be achieved, modularized connecting of multiple rapid connecting pipe fittings can be further achieved, and use is flexible and convenient.

Owner:深圳市安第斯制品有限公司

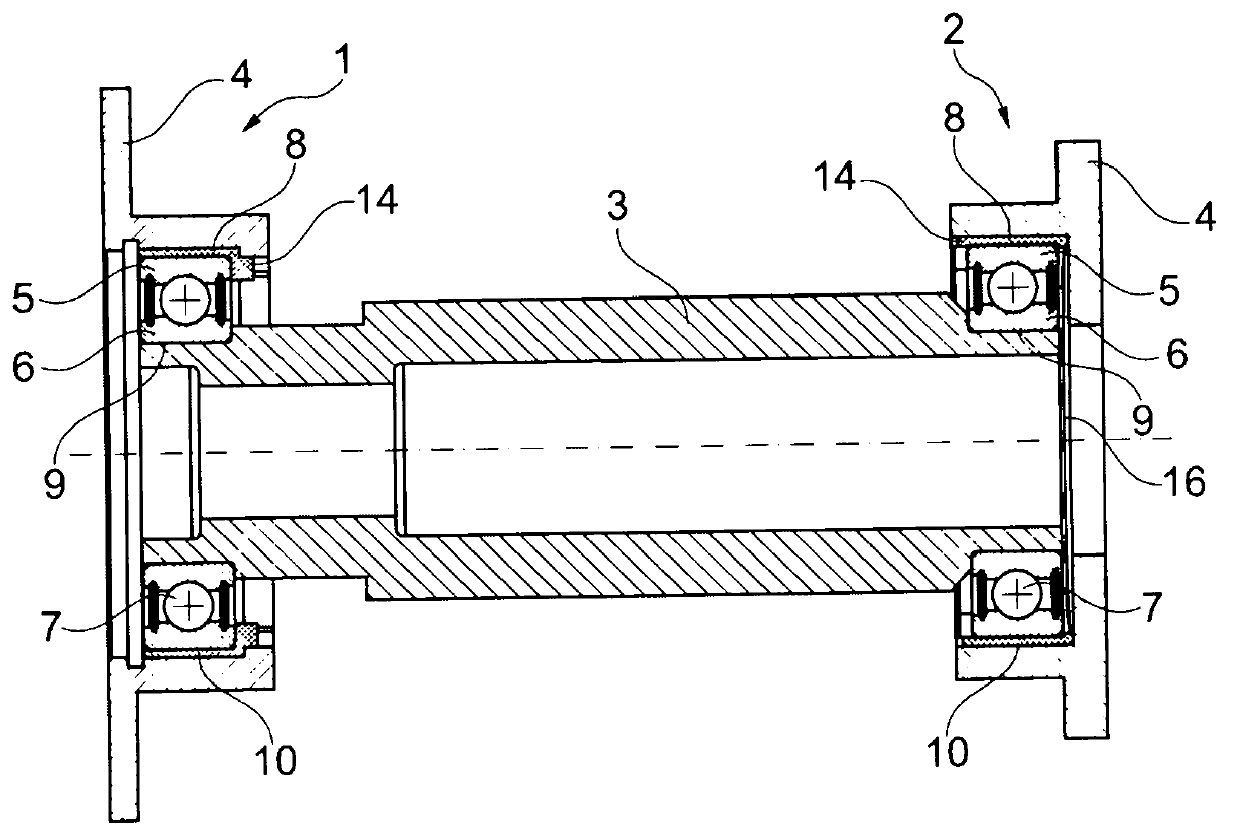

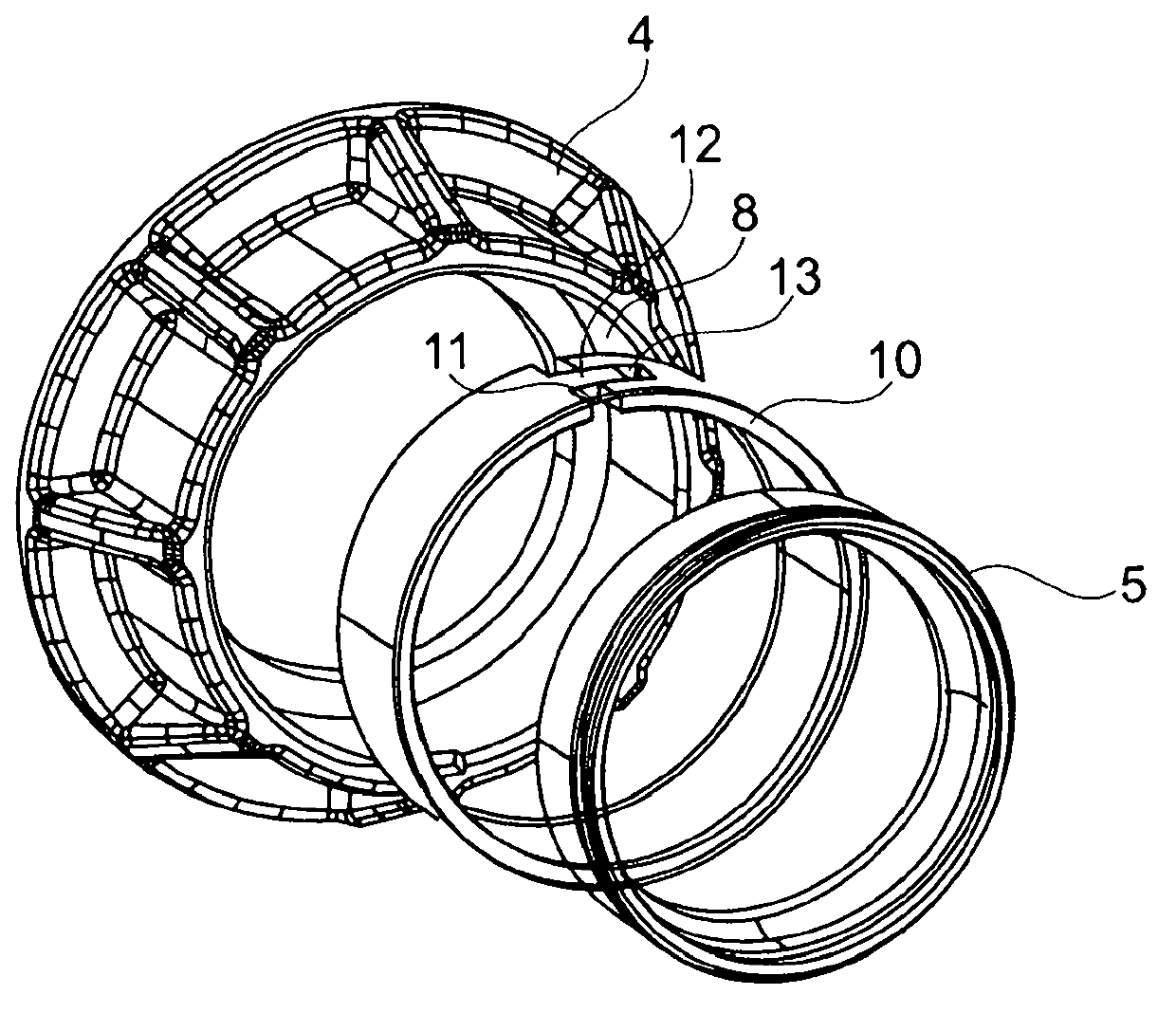

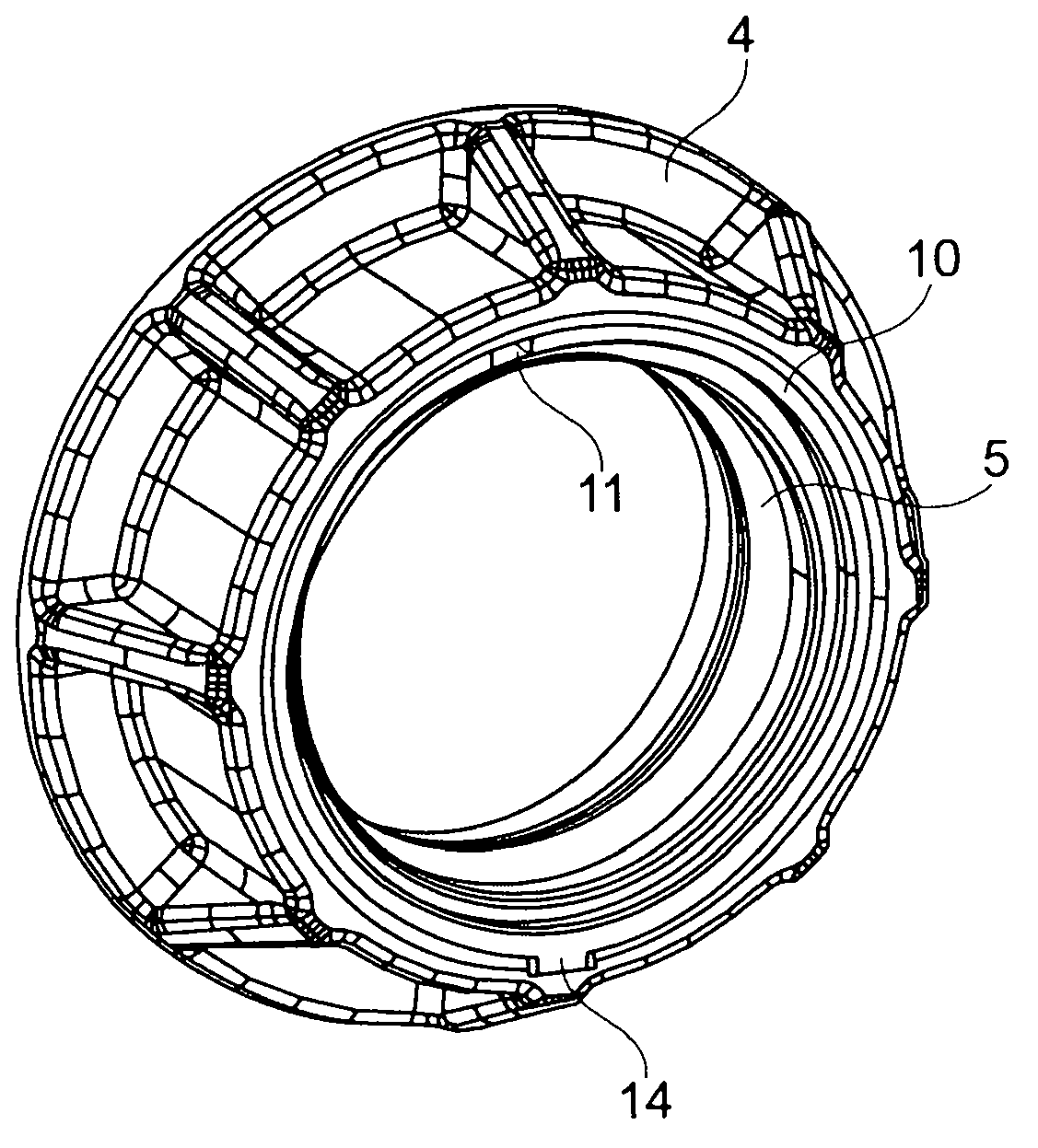

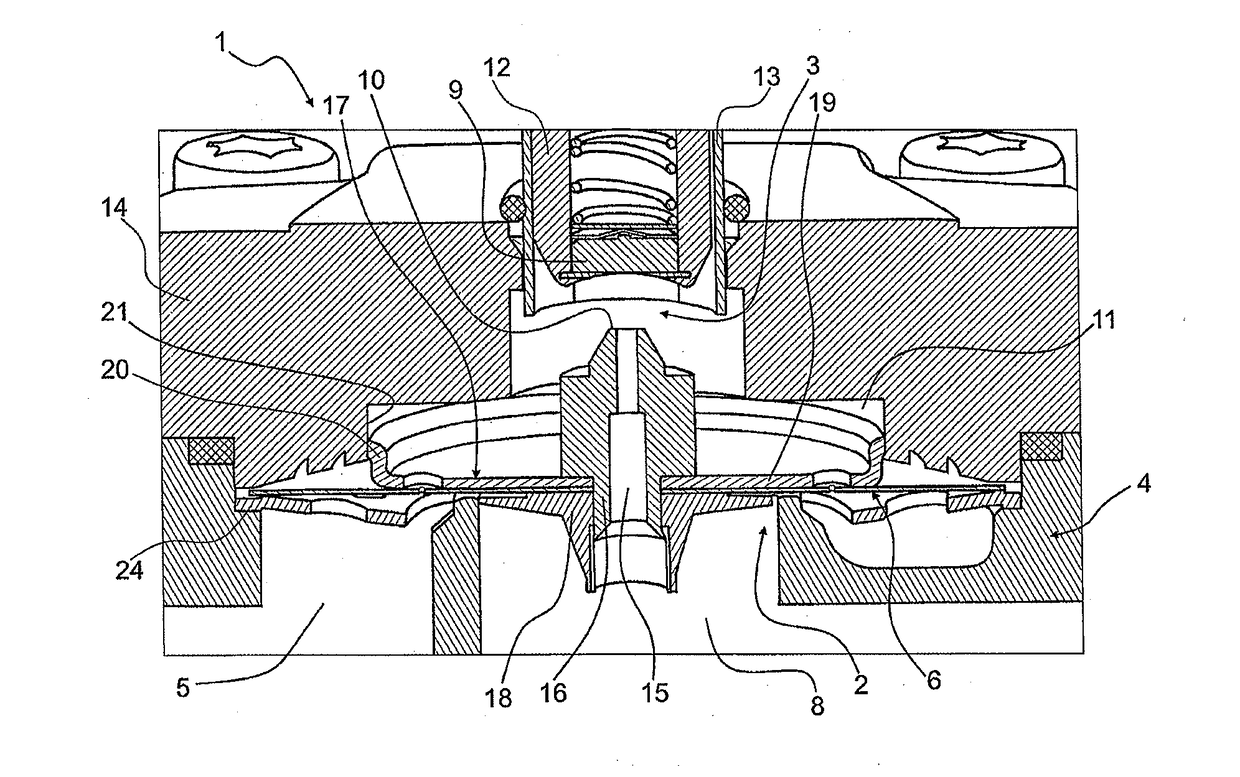

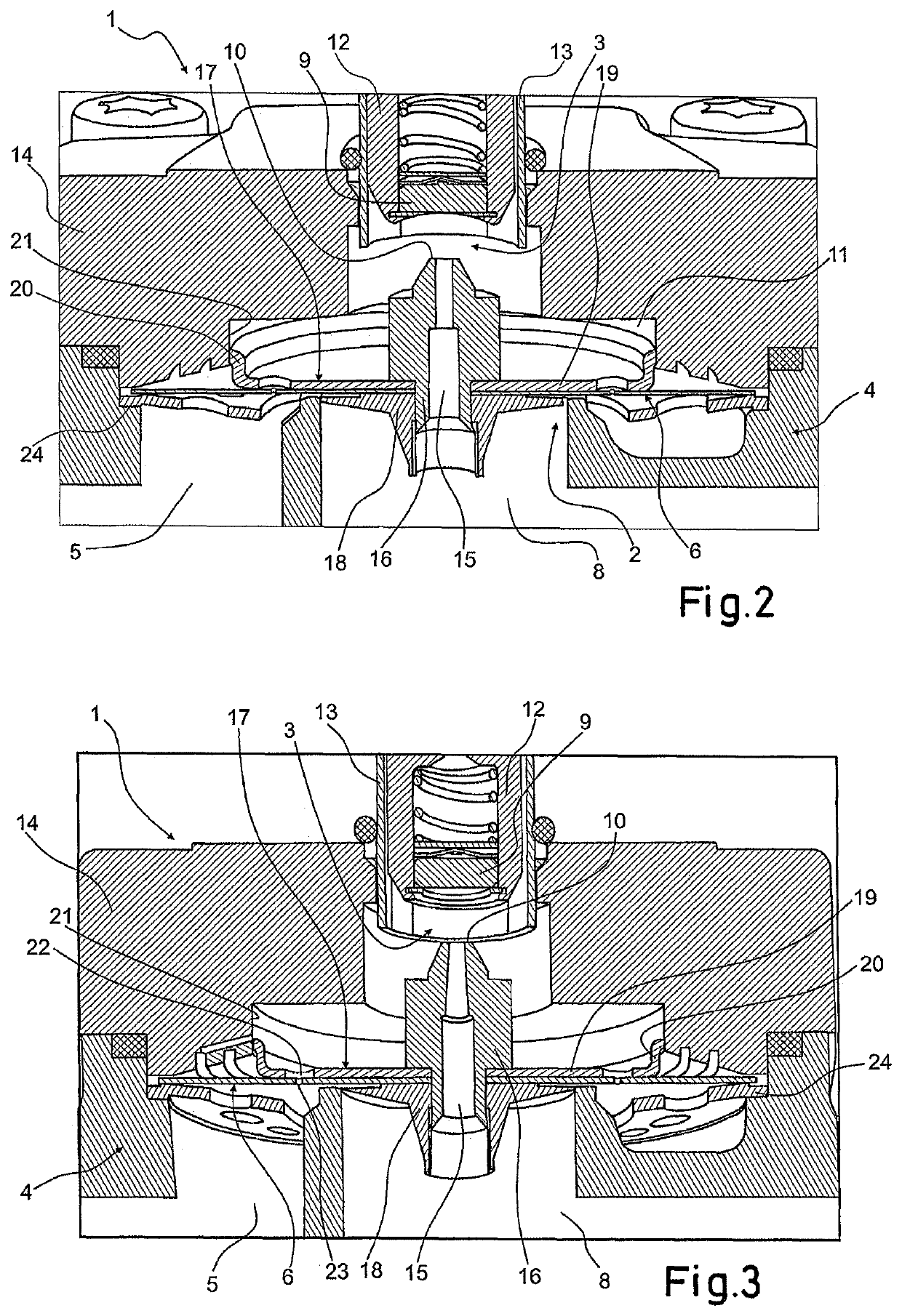

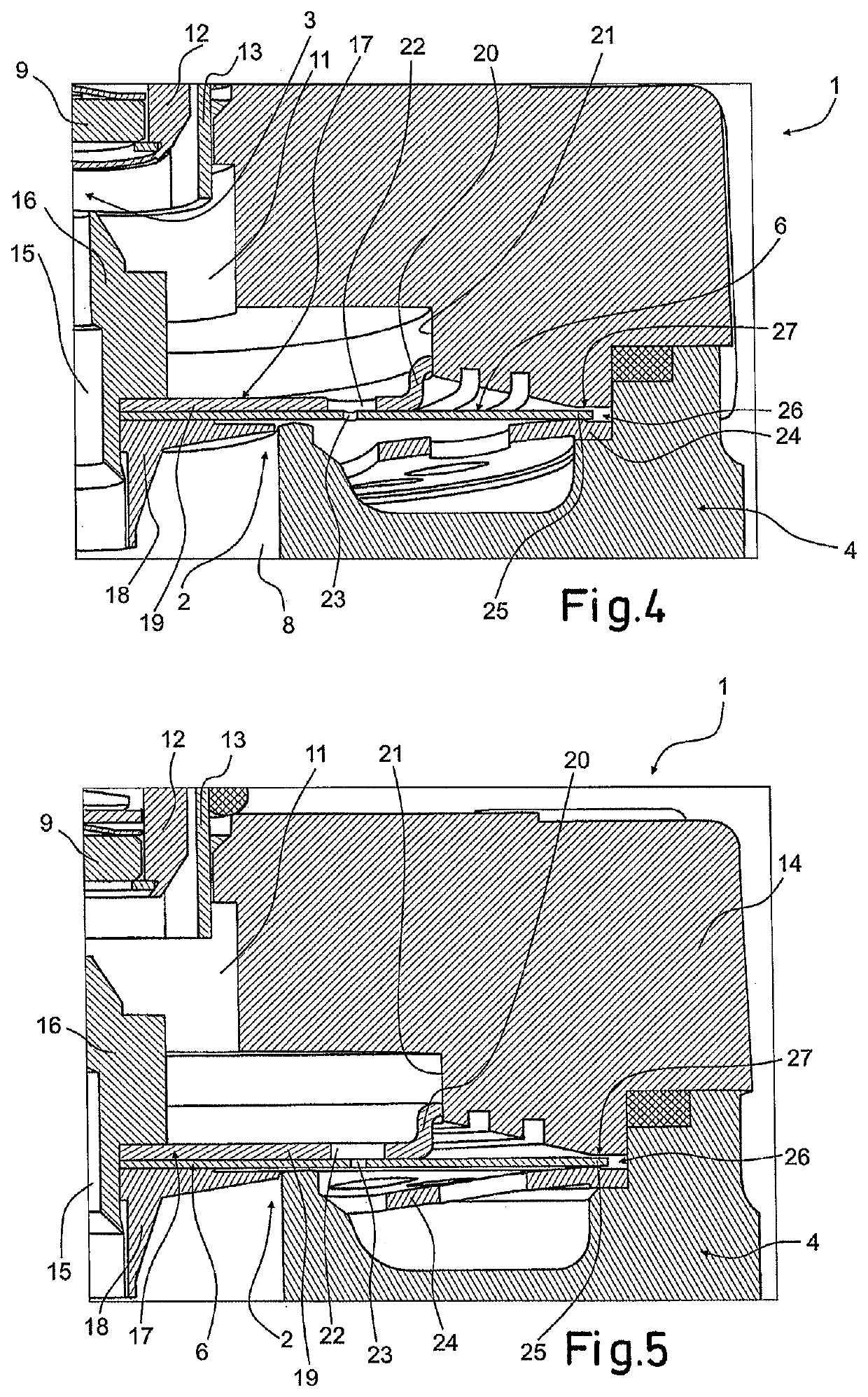

Assembling members using bearings to assemble rotating shaft in housing

InactiveCN102889305ASmall thermal expansionLarge thermal expansionRolling contact bearingsShaftsRotational axisEngineering

The invention relates to assembling members (1, 2) using bearings to assemble a rotating shaft (3) in a housing (4). Each bearing comprises an outer ring (5) and an inner ring (6), each assembling member has an annular accommodation part defined between an inner bearing surface (8) of the housing (4) and an outer bearing surface (9) of a shaft (3), the bearing is arranged in the annular accommodation part, he inner ring (6) is mounted in a clamping manner surrounding the outer bearing surface (9), the thermal expansion of the outer ring (5) is lower than that of the inner bearing surface (8), each assembling member also comprises a sleeve (10) made of thermoplastic material, the sleeve in inserted between the inner bearing surface (8) and the outer ring (5), the thermal expansion of the sleeve is larger than that of the outer ring (5), the sleeve has an annular geometrical shape which is broken by a slot (11) in a circumferential direction, so that the diameter of the sleeve can be changed, and under the ambient temperature, radial clearances are formed between the inner bearing surface and the sleeve and / or between the sleeve and the outer ring.

Owner:TORRINGTON COMPANY

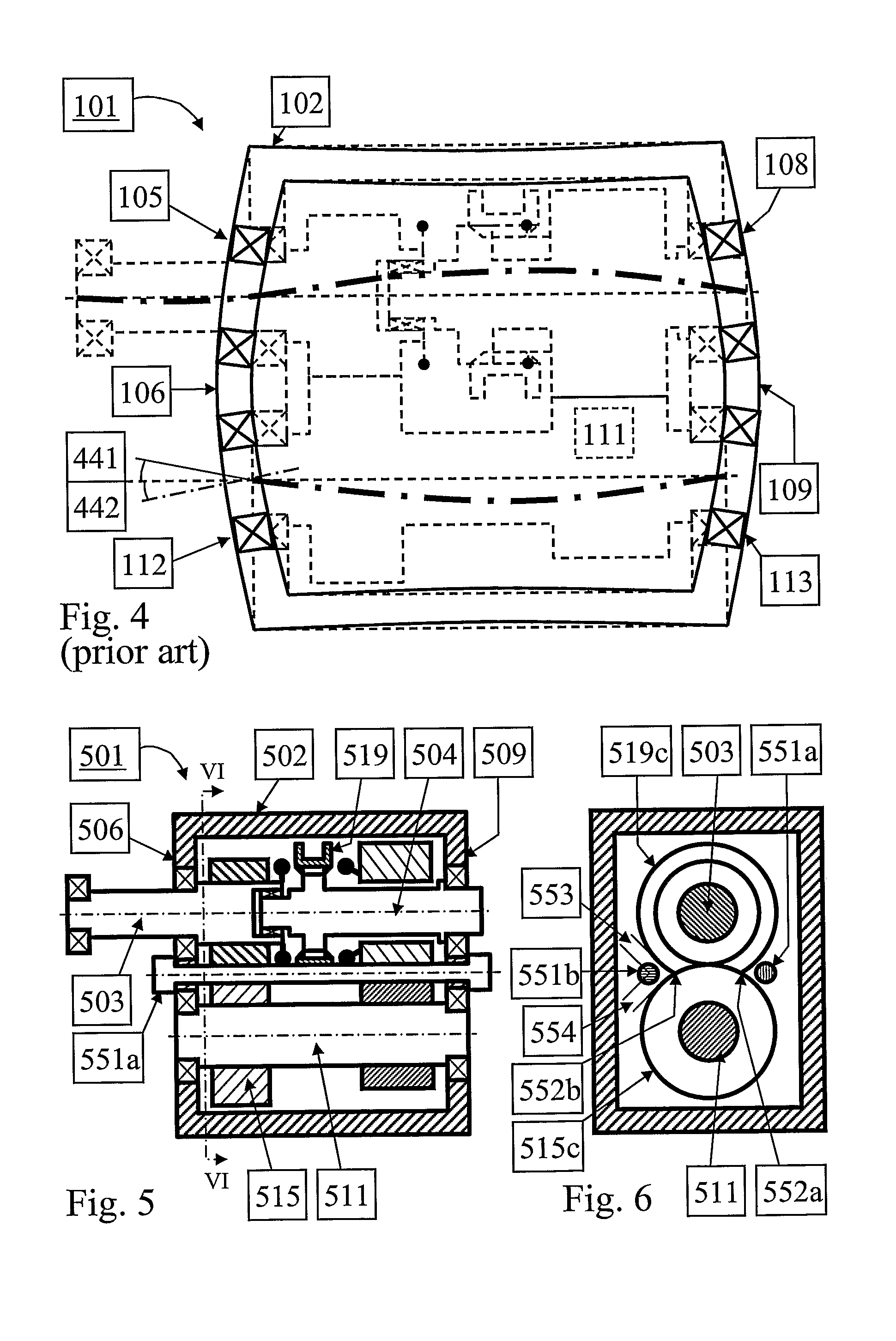

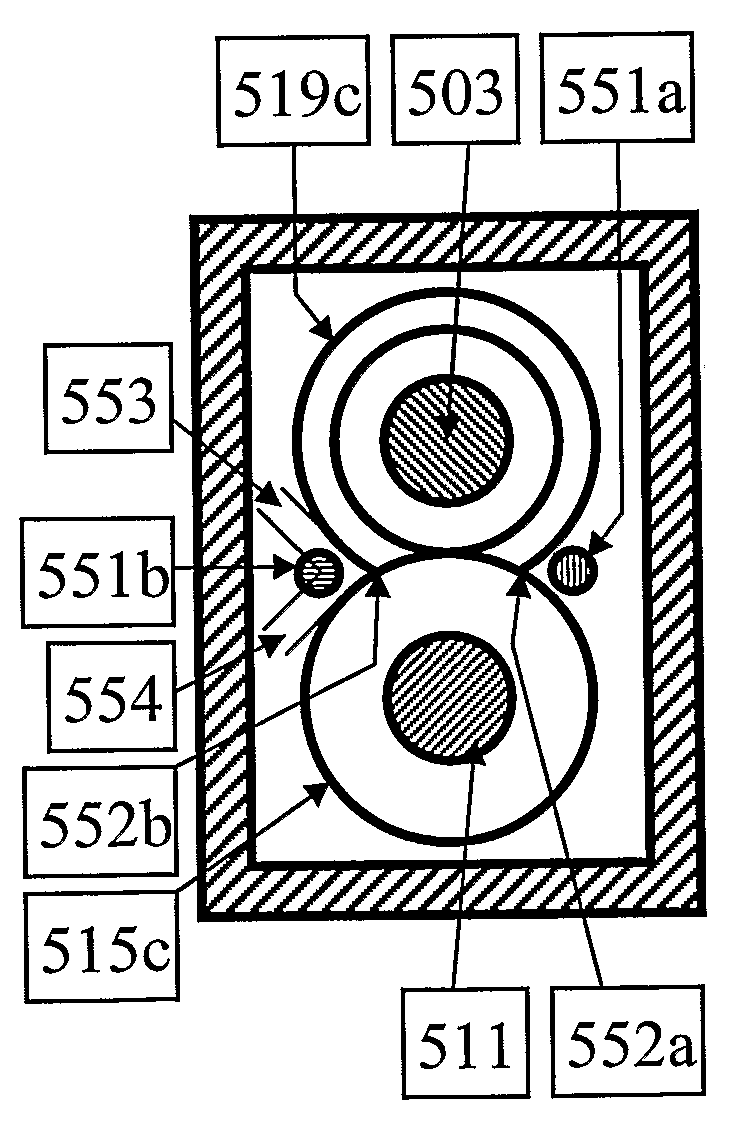

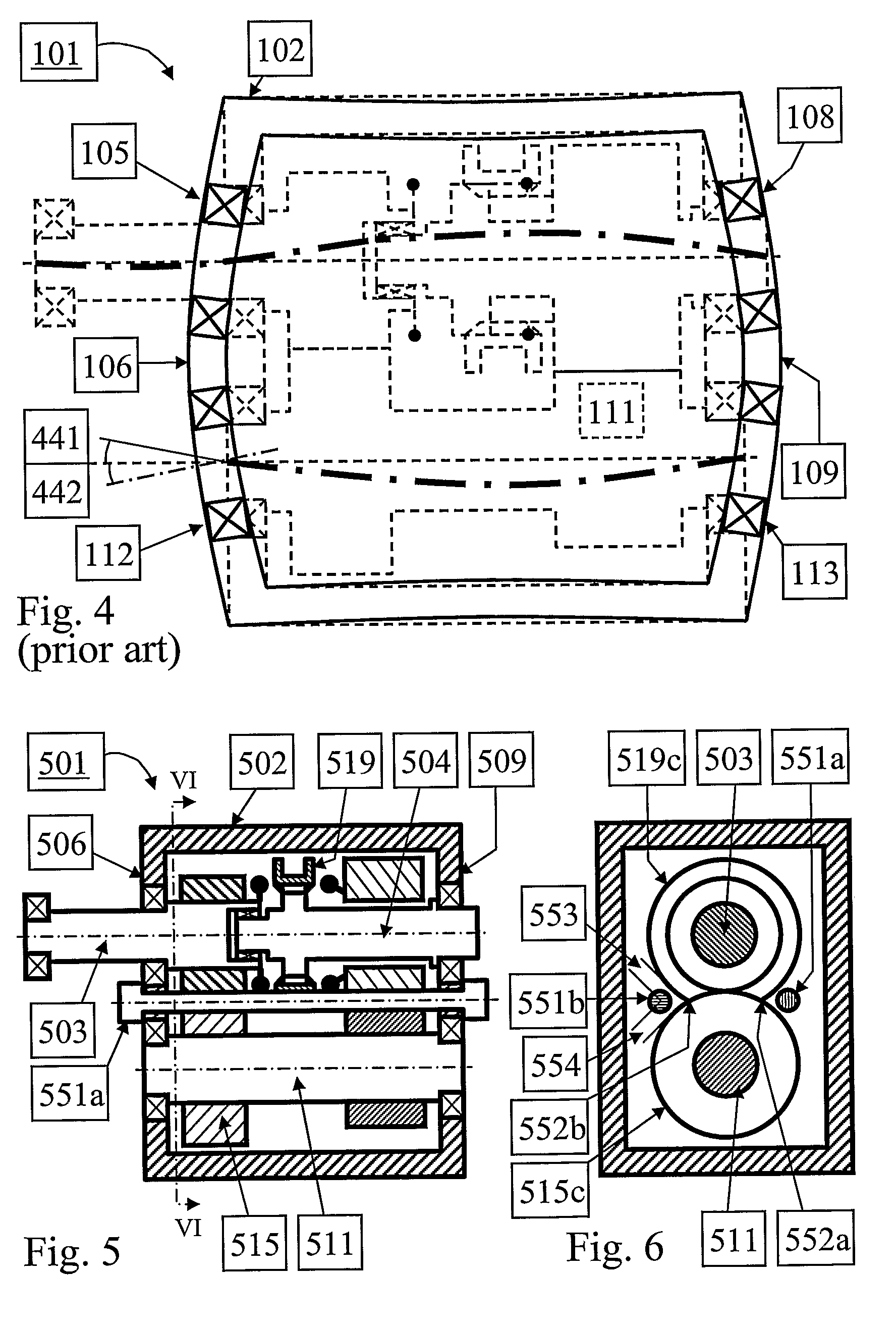

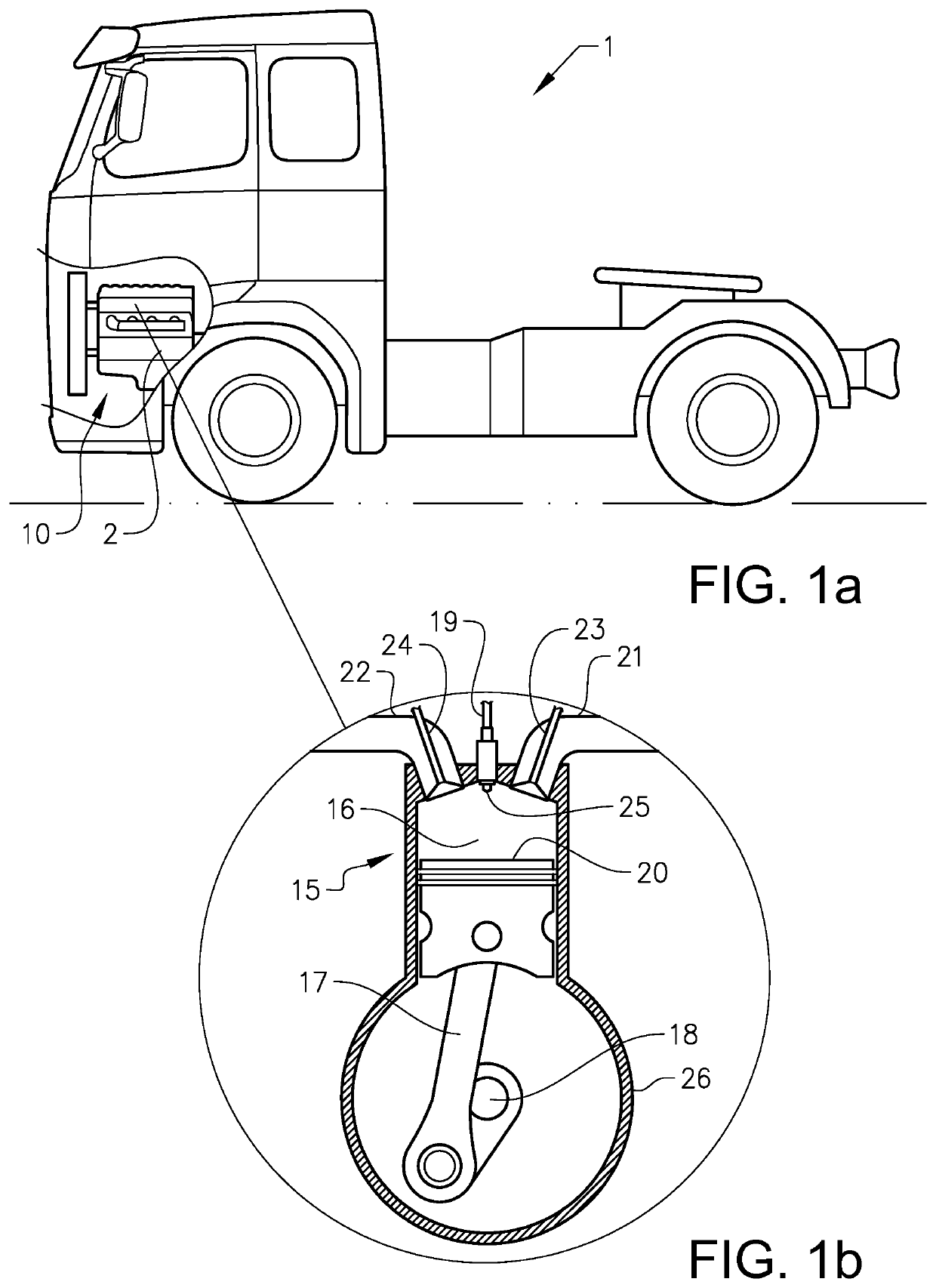

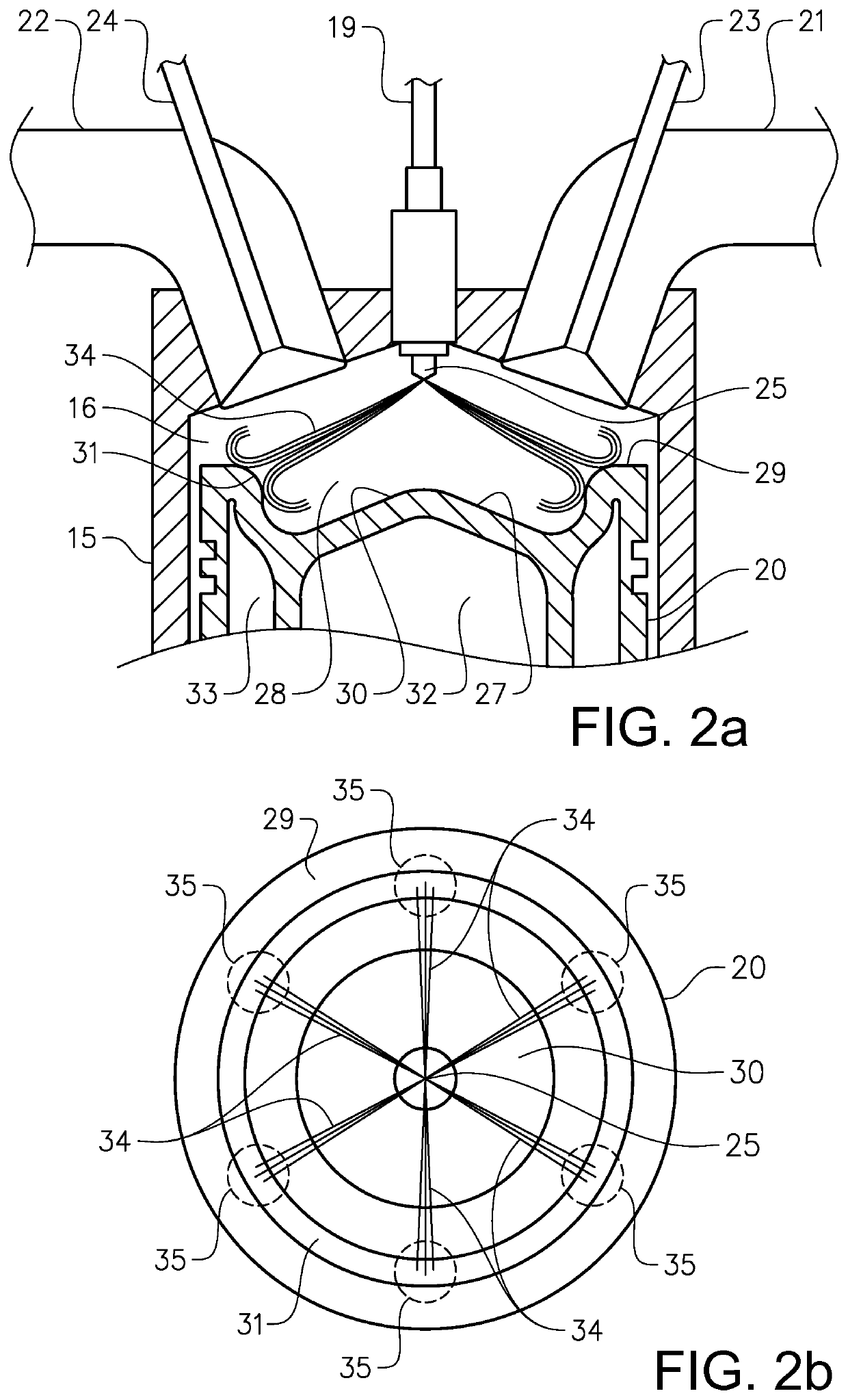

Gear transmission with reduced transmission wall housing deflection

ActiveUS20090100966A1Reduce deflectionEasy to assembleGearboxesGear lubrication/coolingGear wheelGear transmission

A gear transmission is provided including at least a first and a second shaft with substantially fixed and substantially parallel axes of rotation, a transmission housing with a first and a second wall that extends perpendicular to the axes of rotation, and a plurality of gearwheels that are rotationally fixed or rotationally fixable to the shafts. The shafts include at least one input shaft and at least one output shaft, the shafts being suspended by bearings that are seated in the first and second walls. The first wall is connected to the second wall with at least one rod in order to reduce deflections in operation of the first and second walls.

Owner:VOLVO LASTVAGNAR AB

Gear transmission with reduced transmission wall housing deflection

ActiveUS8087323B2Small thicknessIncrease deflectionGearboxesGear lubrication/coolingEngineeringGear transmission

A gear transmission is provided including at least a first and a second shaft with substantially fixed and substantially parallel axes of rotation, a transmission housing with a first and a second wall that extends perpendicular to the axes of rotation, and a plurality of gearwheels that are rotationally fixed or rotationally fixable to the shafts. The shafts include at least one input shaft and at least one output shaft, the shafts being suspended by bearings that are seated in the first and second walls. The first wall is connected to the second wall with at least one rod in order to reduce deflections in operation of the first and second walls.

Owner:VOLVO LASTVAGNAR AB

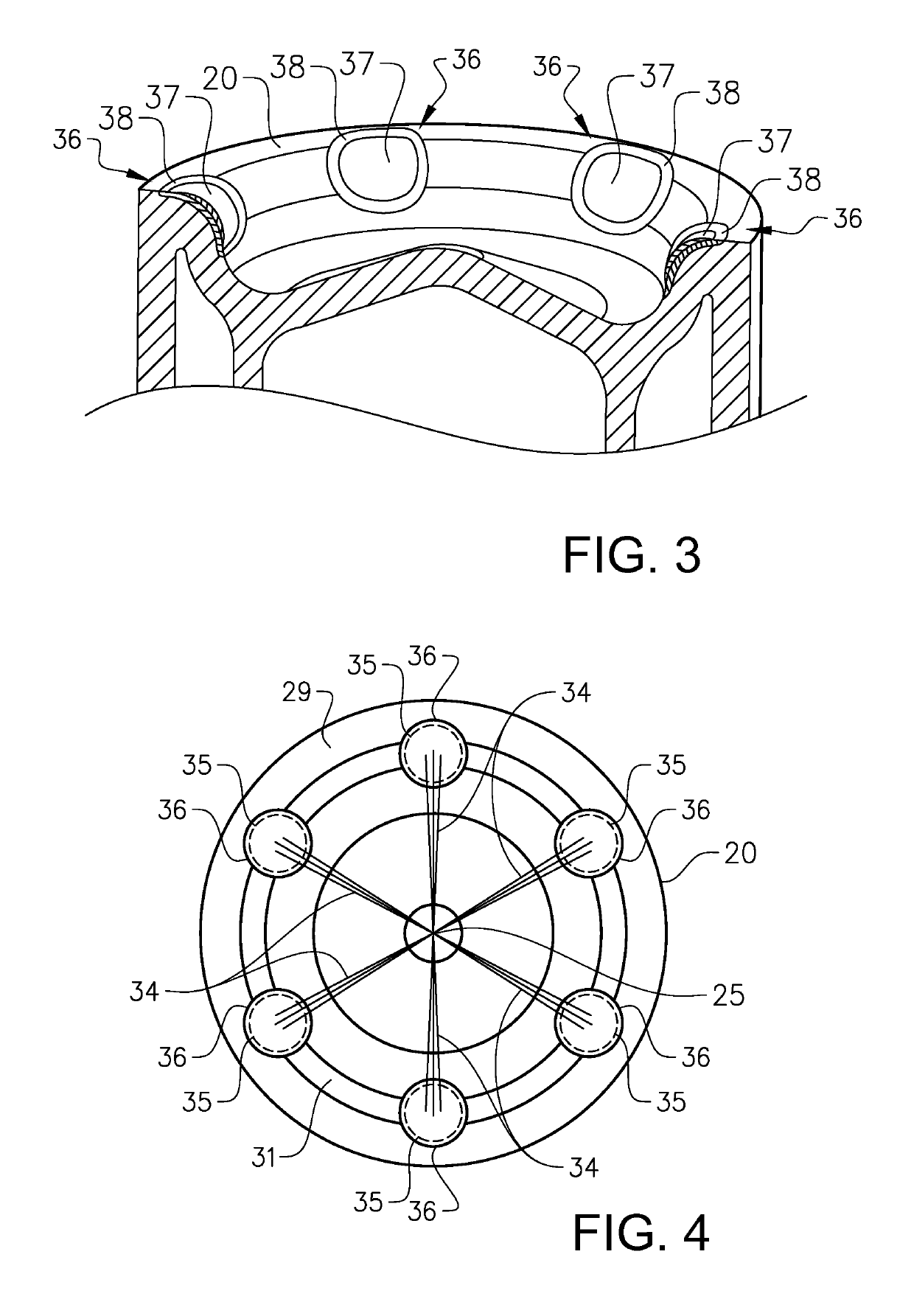

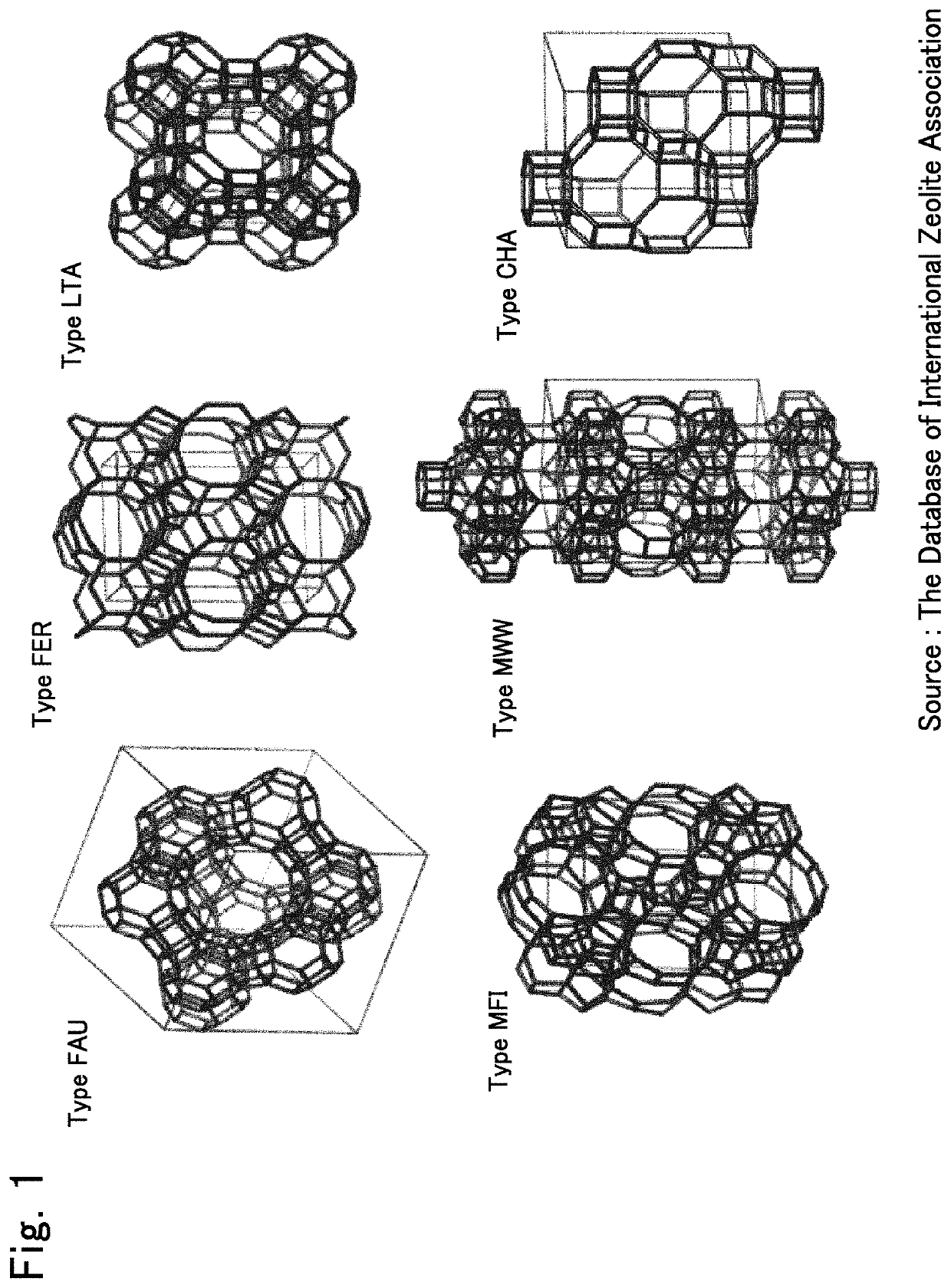

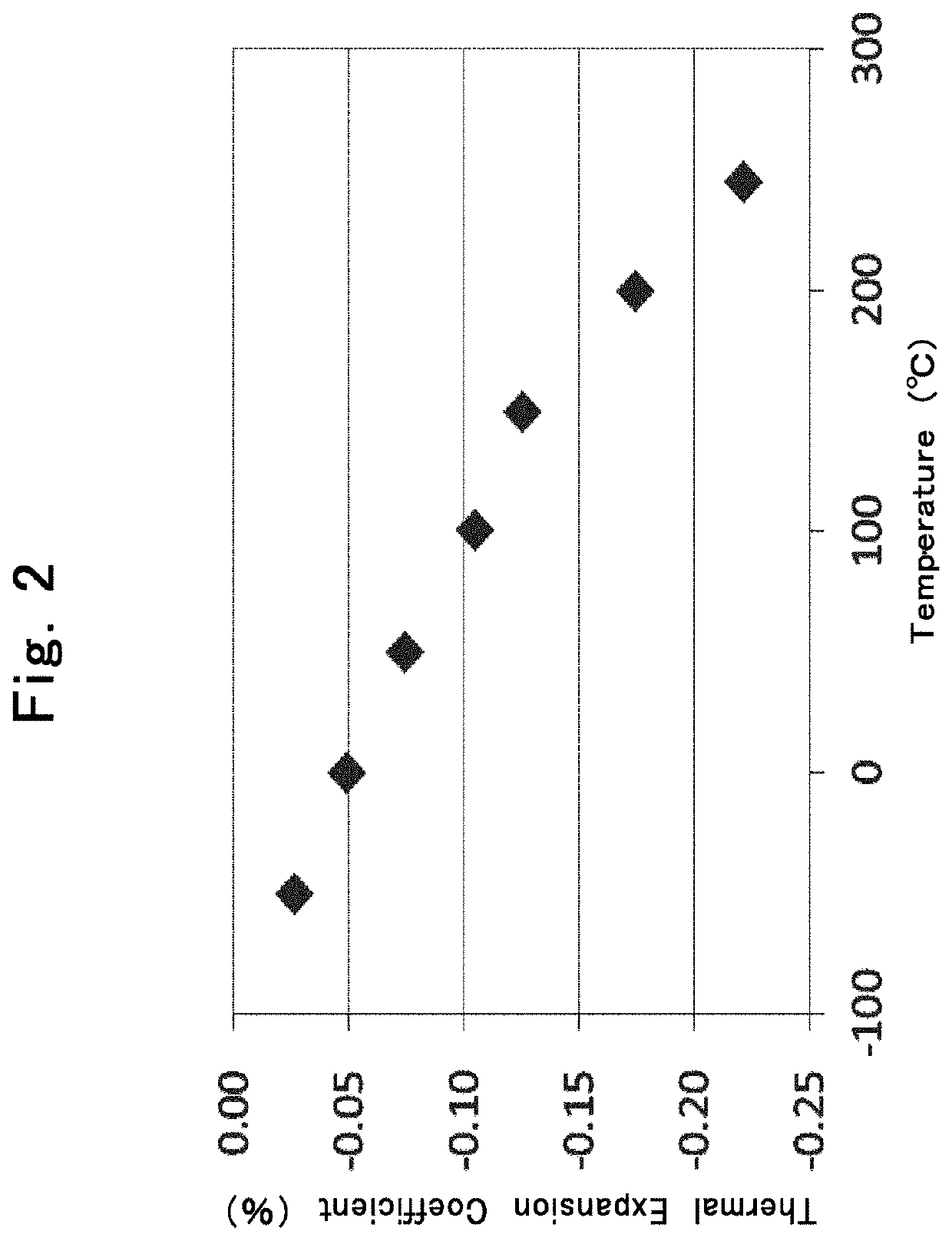

Filler for resinous composition, filler-containing slurry composition and filler-containing resinous composition

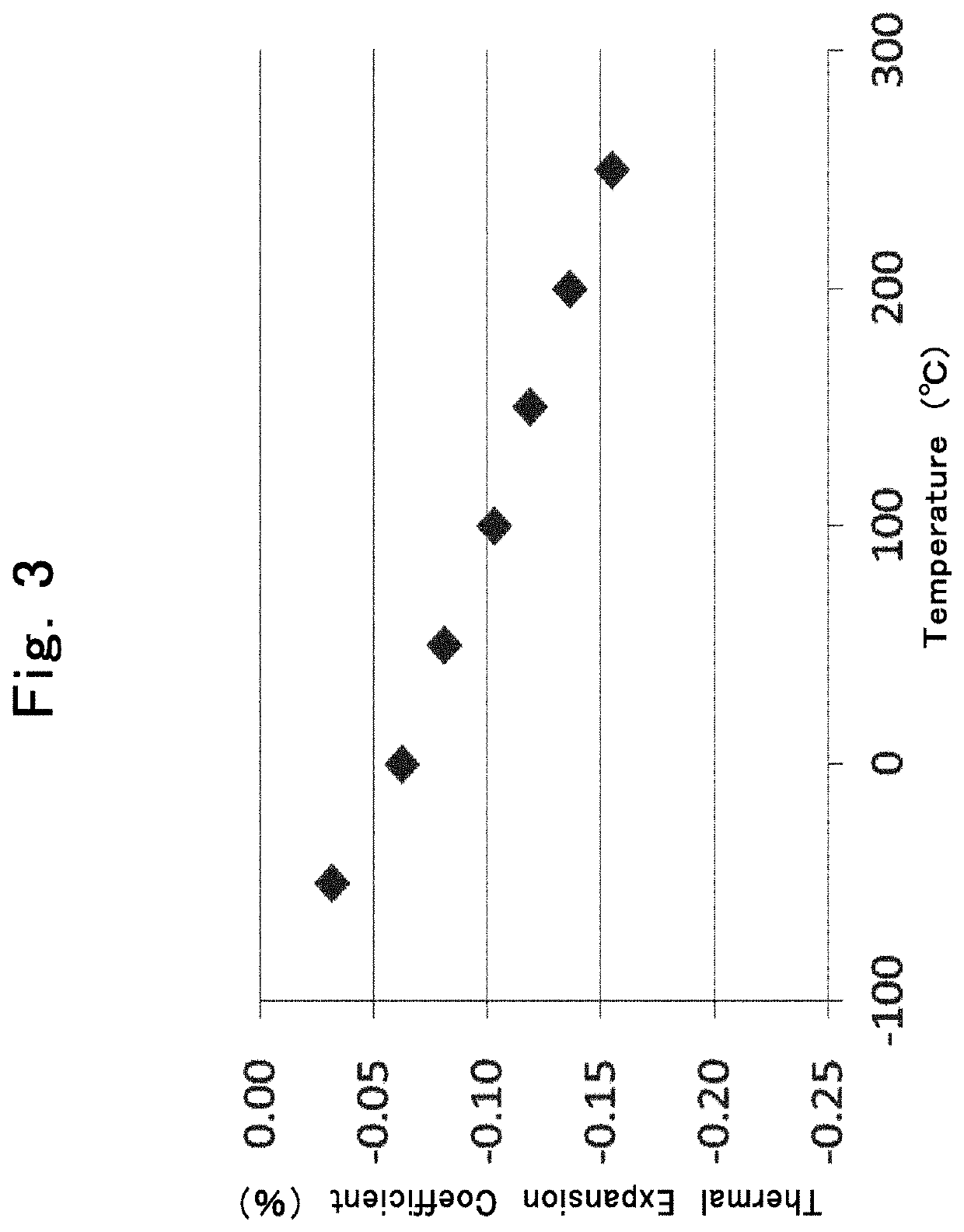

InactiveUS20200040162A1Negative coefficientPromote and accelerate yellowingSemiconductor/solid-state device detailsPrinted circuit aspectsPolymer chemistrySurface reaction

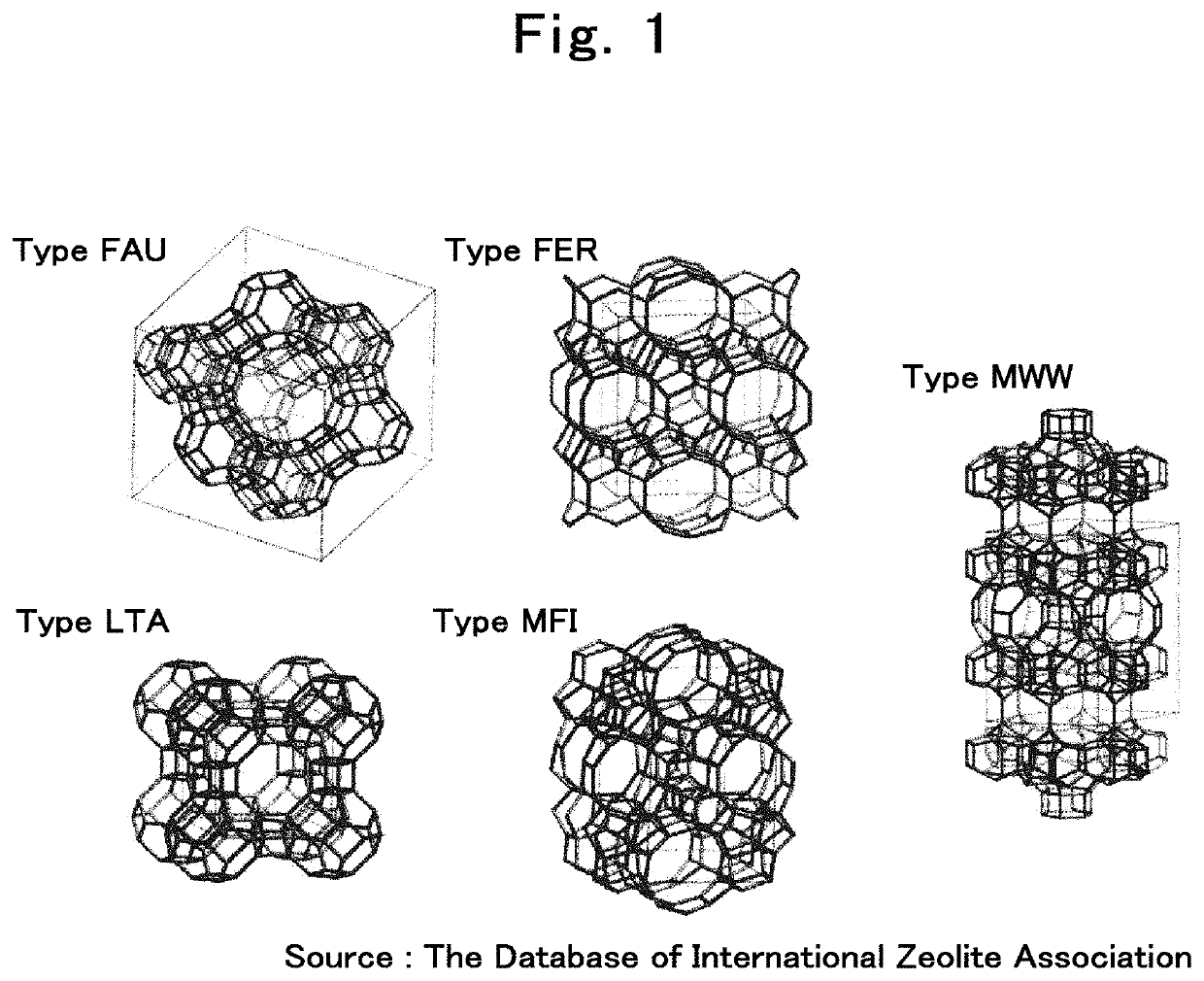

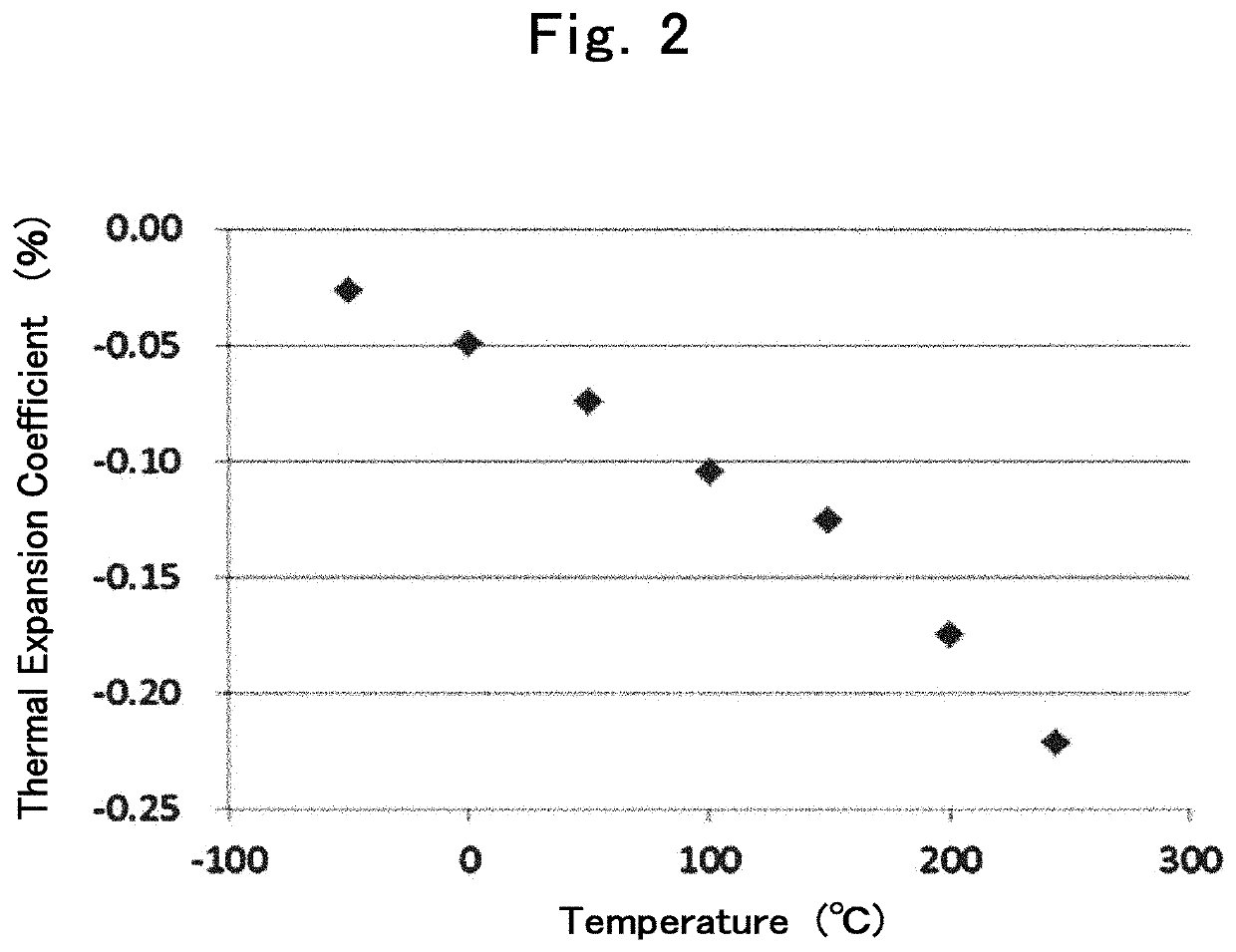

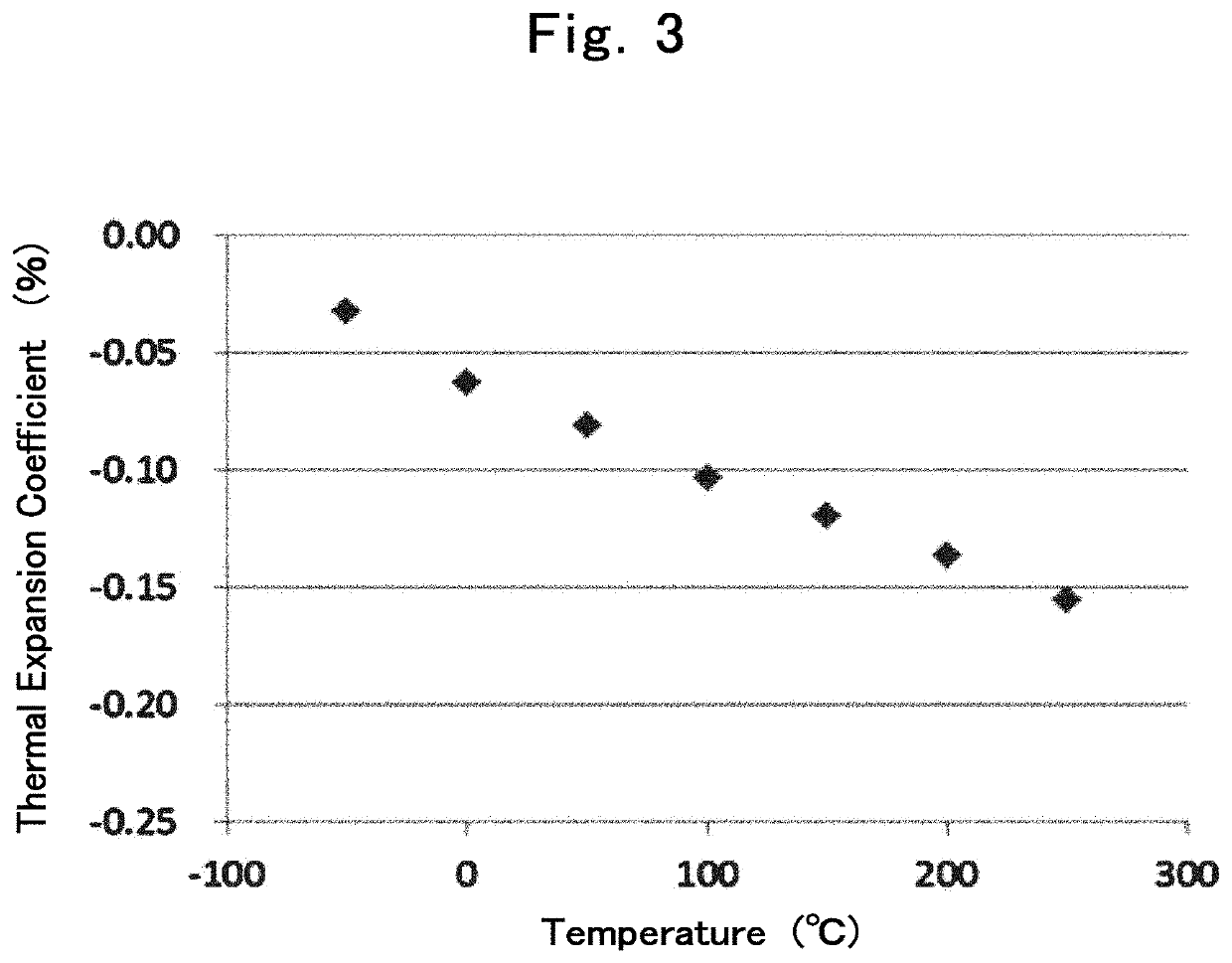

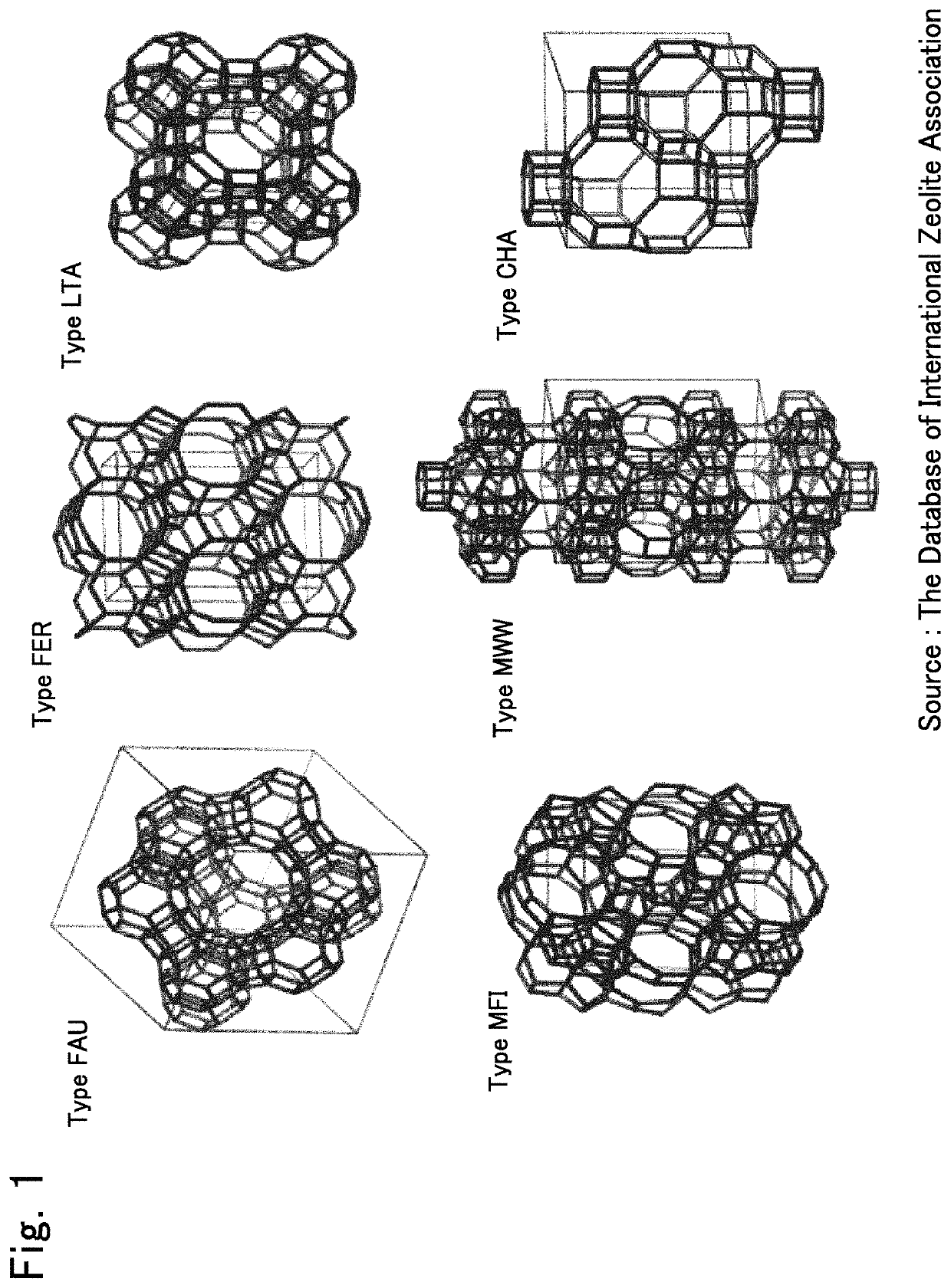

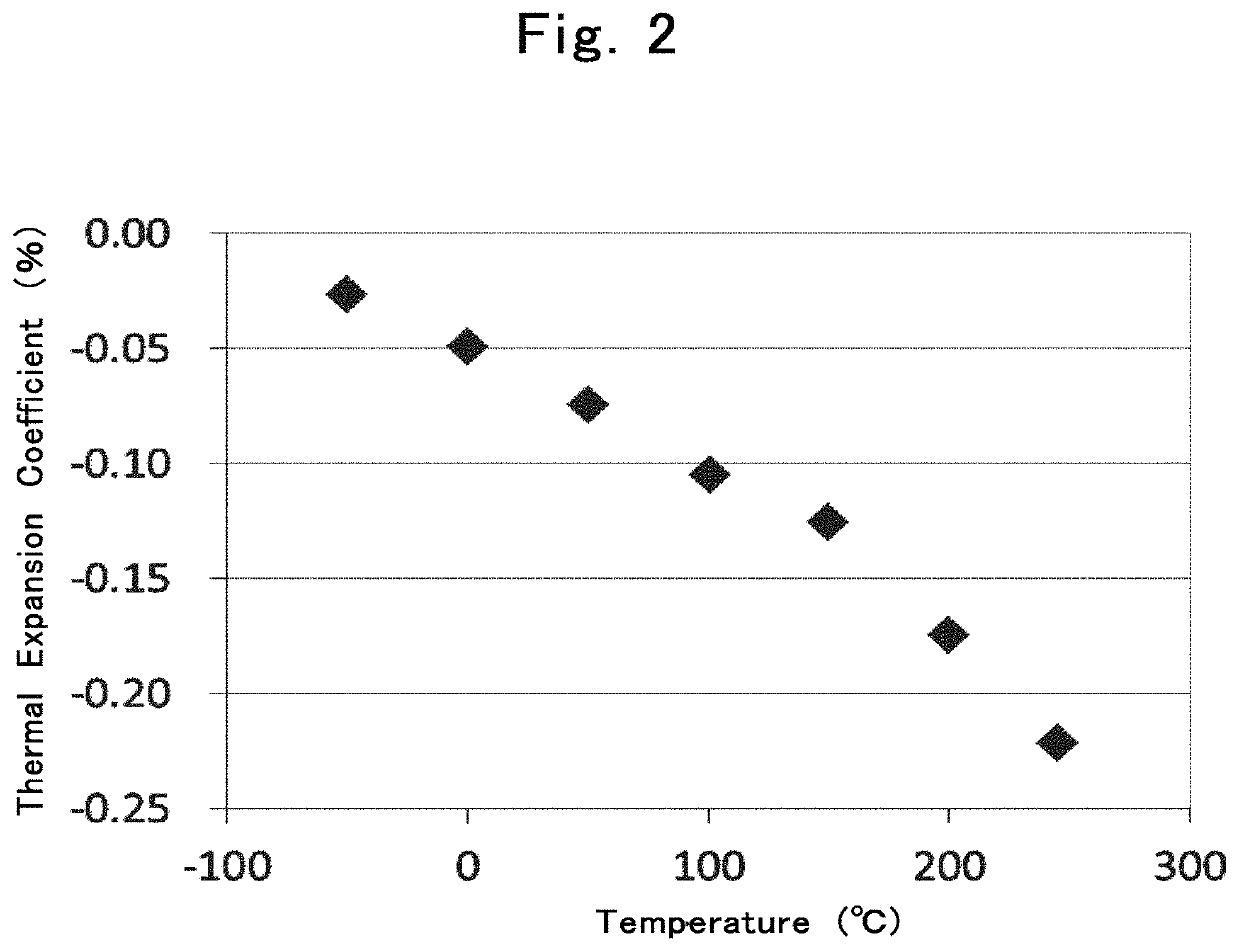

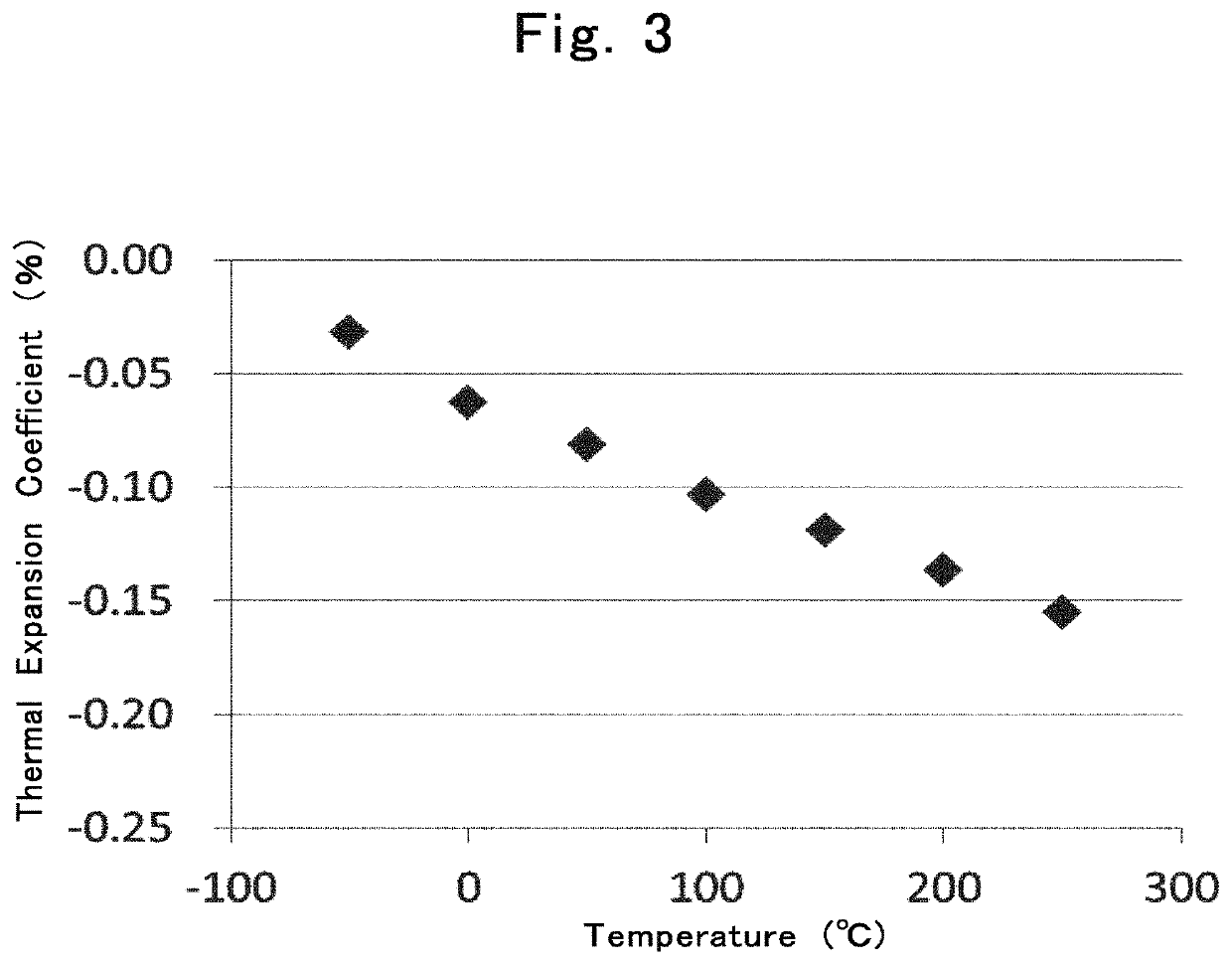

A filler for resinous composition is contained and used in resinous composition, and includes: a crystalline siliceous particulate material with a crystal structure made of at least one member selected from the group consisting of type FAU, type FER, type LTA and type MFI, and type MWW; and a surface treatment agent including an organic silica compound reacted with or adhered to a surface of the crystalline siliceous particulate material; the filler including the surface treatment agent in an amount falling in a range allowing the filler to exhibit a negative thermal expansion coefficient.

Owner:ADMATECHS CO LTD

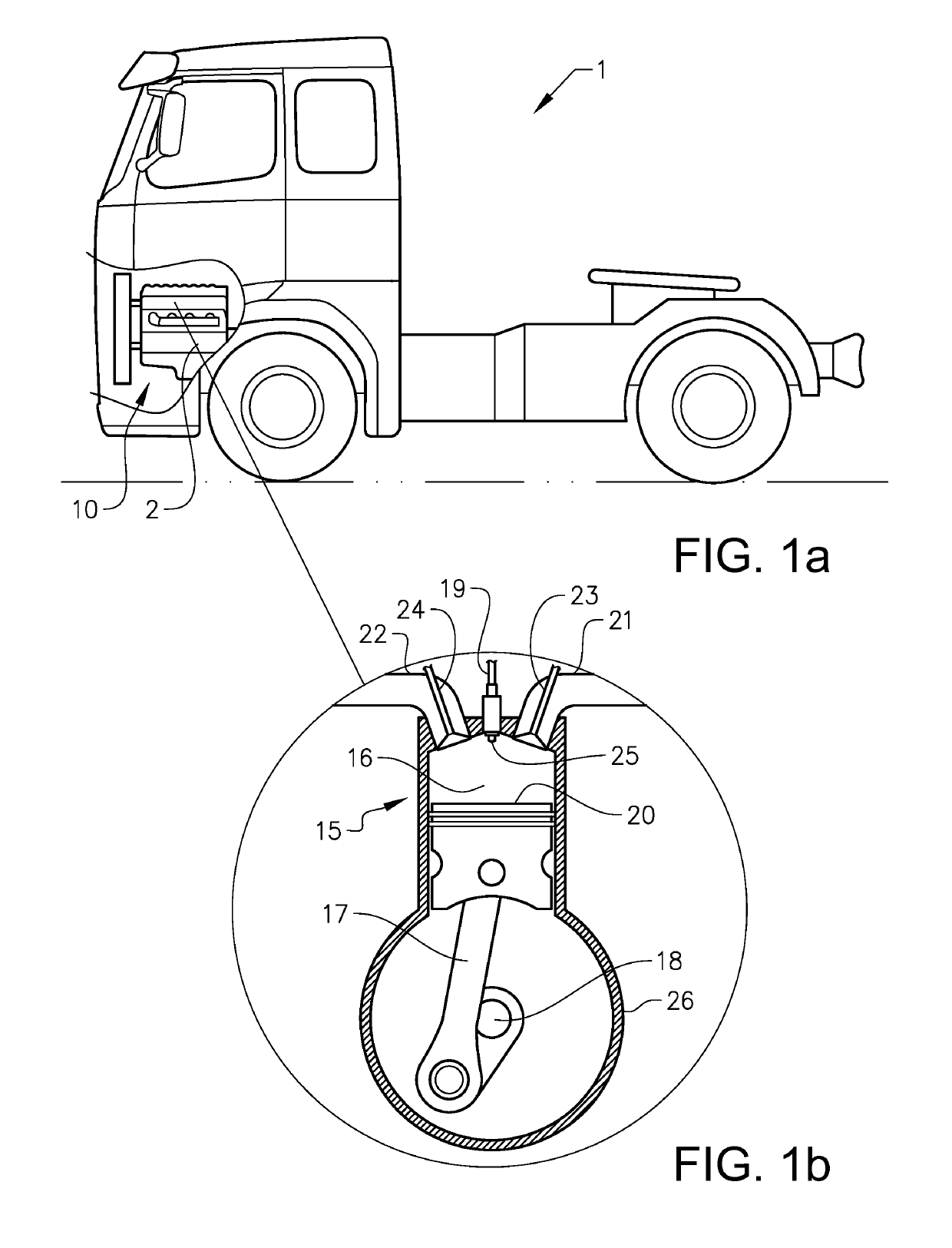

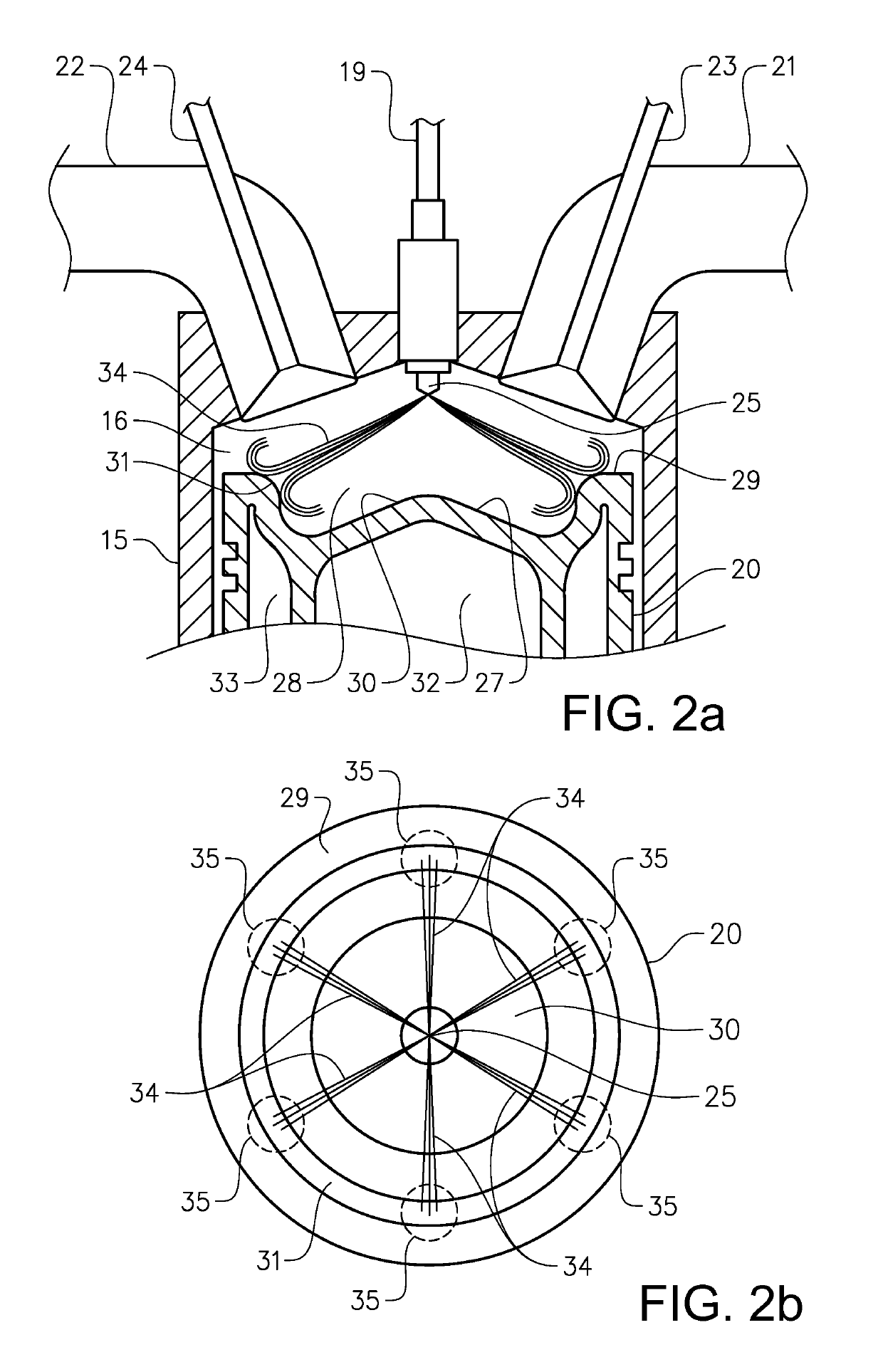

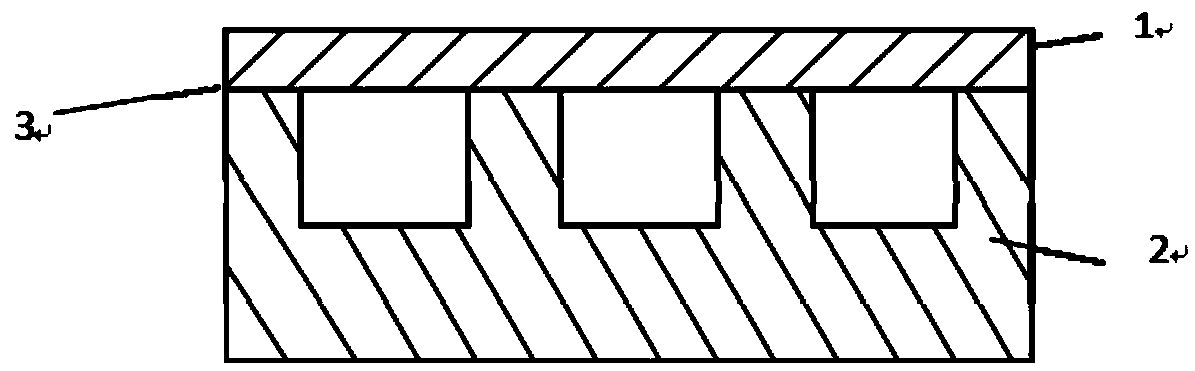

A piston for a cylinder for an internal combustion engine

ActiveUS20190128213A1Satisfactory bondingEqually distributedMolten spray coatingInternal combustion piston enginesExternal combustion engineEngineering

A piston for a cylinder for an internal combustion engine has a piston bowl surface adapted for facing a combustion chamber of the cylinder, the piston bowl surface being provided with a thermal barrier coating layer, wherein the thermal barrier coating layer is provided on a plurality of circumferentially spaced surface parts of the piston bowl surface. A method for producing a piston for a cylinder for an internal combustion engine includes the steps of providing a piston for a cylinder for an internal combustion engine, the piston having a piston bowl surface adapted for facing a combustion chamber of the cylinder, and providing the piston bowl surface with a thermal barrier coating layer, wherein the step of providing the thermal barrier coating layer is made on a plurality of circumferentially spaced surface parts of the piston bowl surface.

Owner:VOLVO LASTVAGNAR AB

Filler for resinous composition, filler-containing slurry composition and filler-containing resinous composition as well as production process for filler for resinous composition

ActiveUS20210017392A1Negative thermal expansion coefficientReduce contentInksFaujasite aluminosilicate zeoliteElectric devicesBismuth

A filler for resinous composition is contained and used in resinous composition constituting electronic packaging material for electronic device, and includes: a filler ingredient including a crystalline siliceous material with a crystal structure made of at least one member selected from the group consisting of type FAU, type FER, type LTA, type MFI and type CHA, and / or type MWW, wherein: the filler ingredient is free of any activity when evaluated by an “NH3-TPD” method; and includes the crystalline siliceous material in an amount falling in a range allowing the filler ingredient to exhibit a negative thermal expansion coefficient. The filler ingredient may further be free of a surface in which silver, copper, zinc, mercury, tin, lead, bismuth, cadmium, chromium, cobalt and nickel are exposed.

Owner:ADMATECHS CO LTD

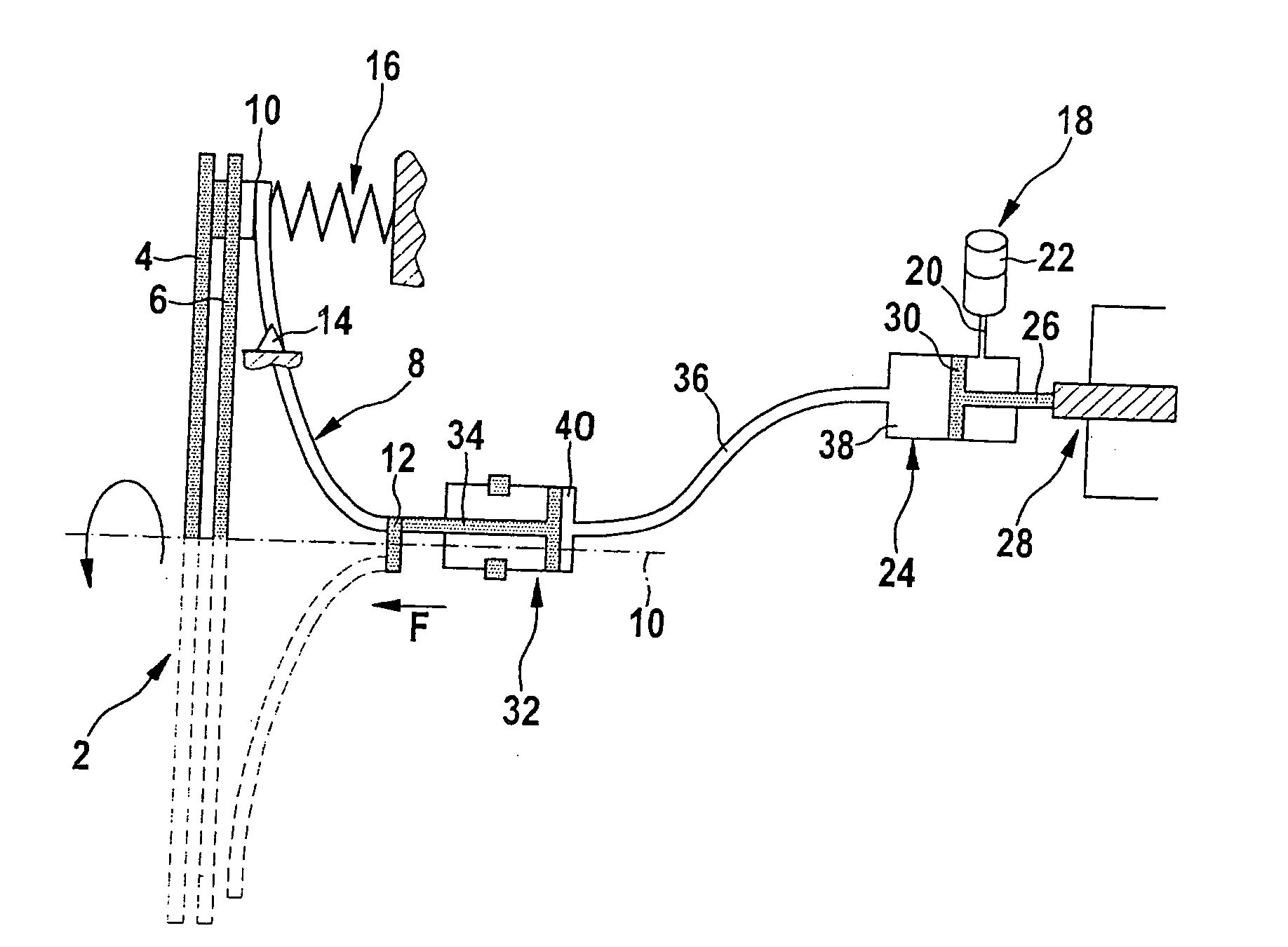

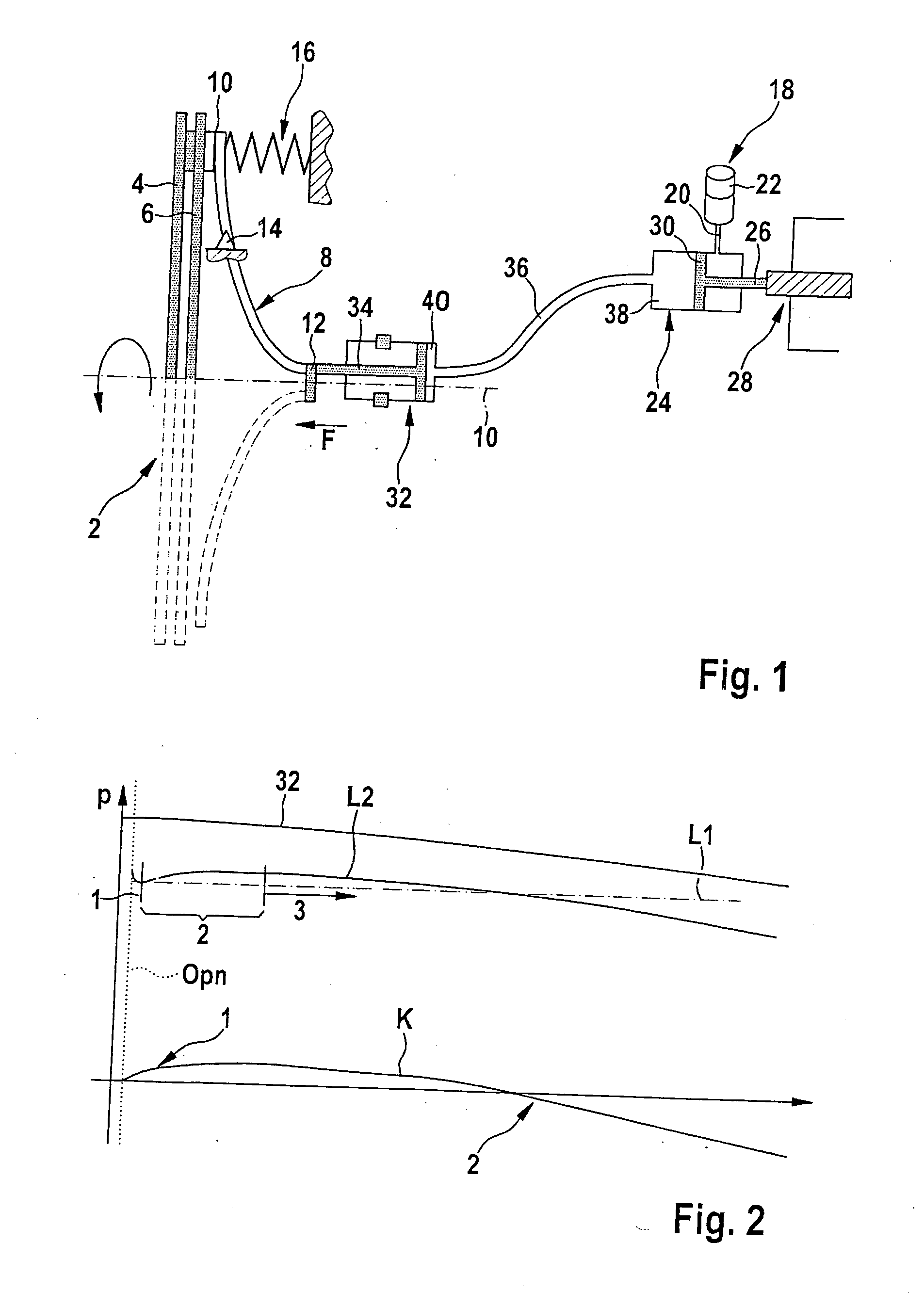

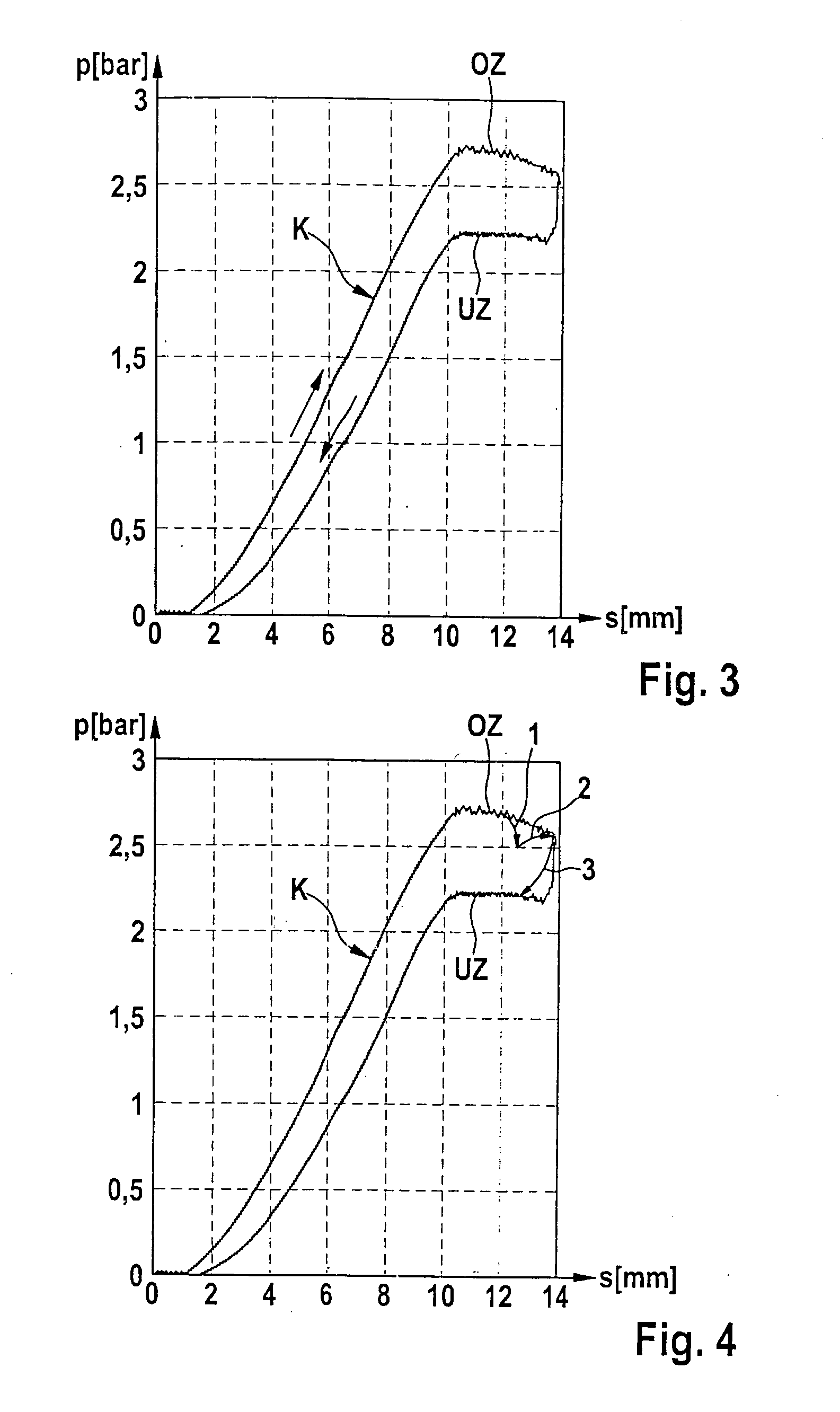

Method for compensating for volume changes of an hydraulic fluid in an hydraulic actuating device for actuating a clutch, and hydraulic actuating device

InactiveUS20110196589A1Large thermal expansionDigital data processing detailsFluid actuated clutchesMaster cylinderActuator

In a method for compensating for volume changes of a hydraulic fluid in an actuating device used for actuating a clutch, which actuating device includes a master cylinder, an actuator connected to a piston of the master cylinder, and a slave cylinder hydraulically connected to the master cylinder for disengaging the clutch. The position of the piston of the master cylinder is corrected as a function of temperature and that the actuating device include an element for the temperature-dependent correction of the position of the piston of the master cylinder.

Owner:ROBERT BOSCH GMBH

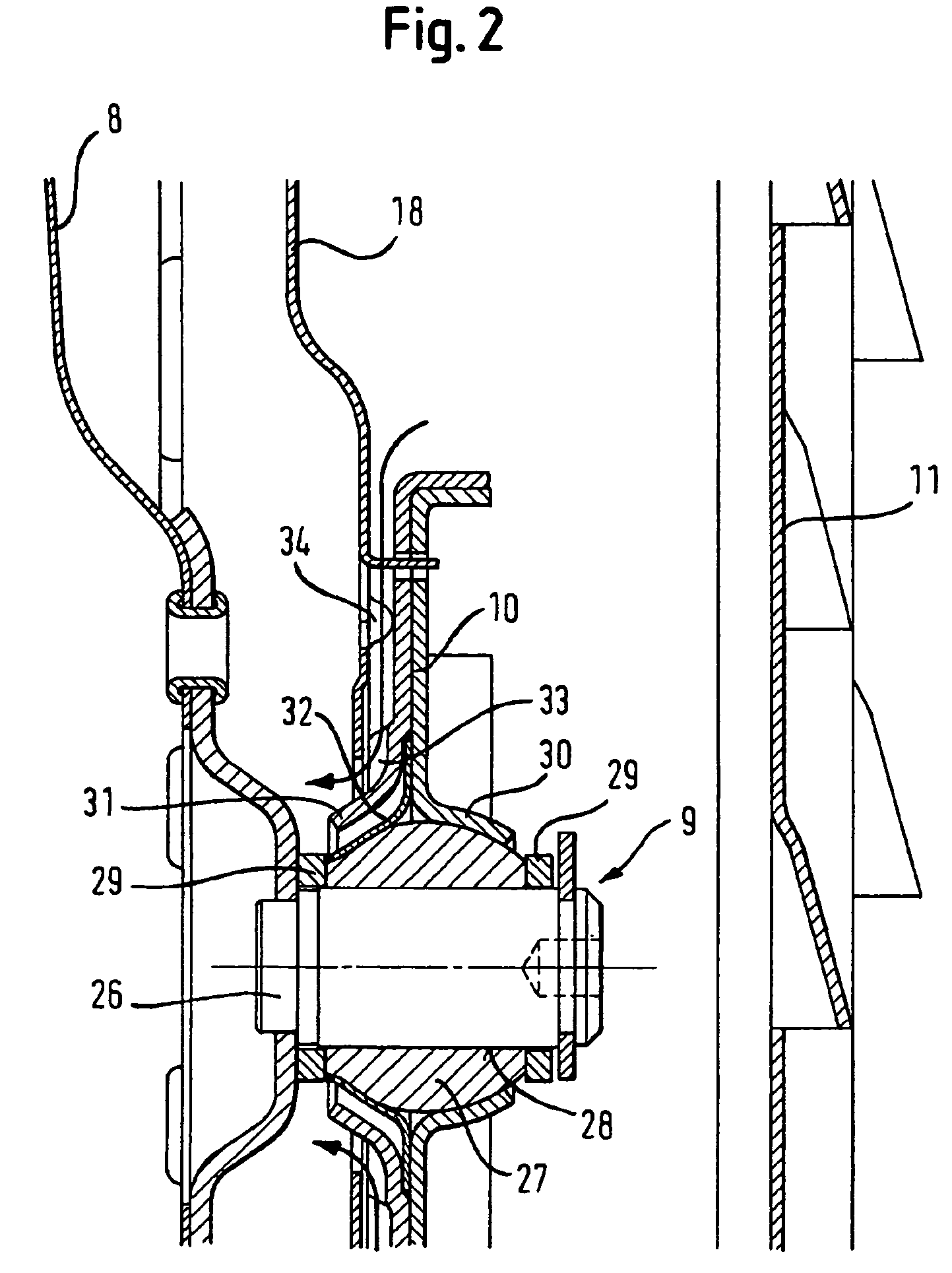

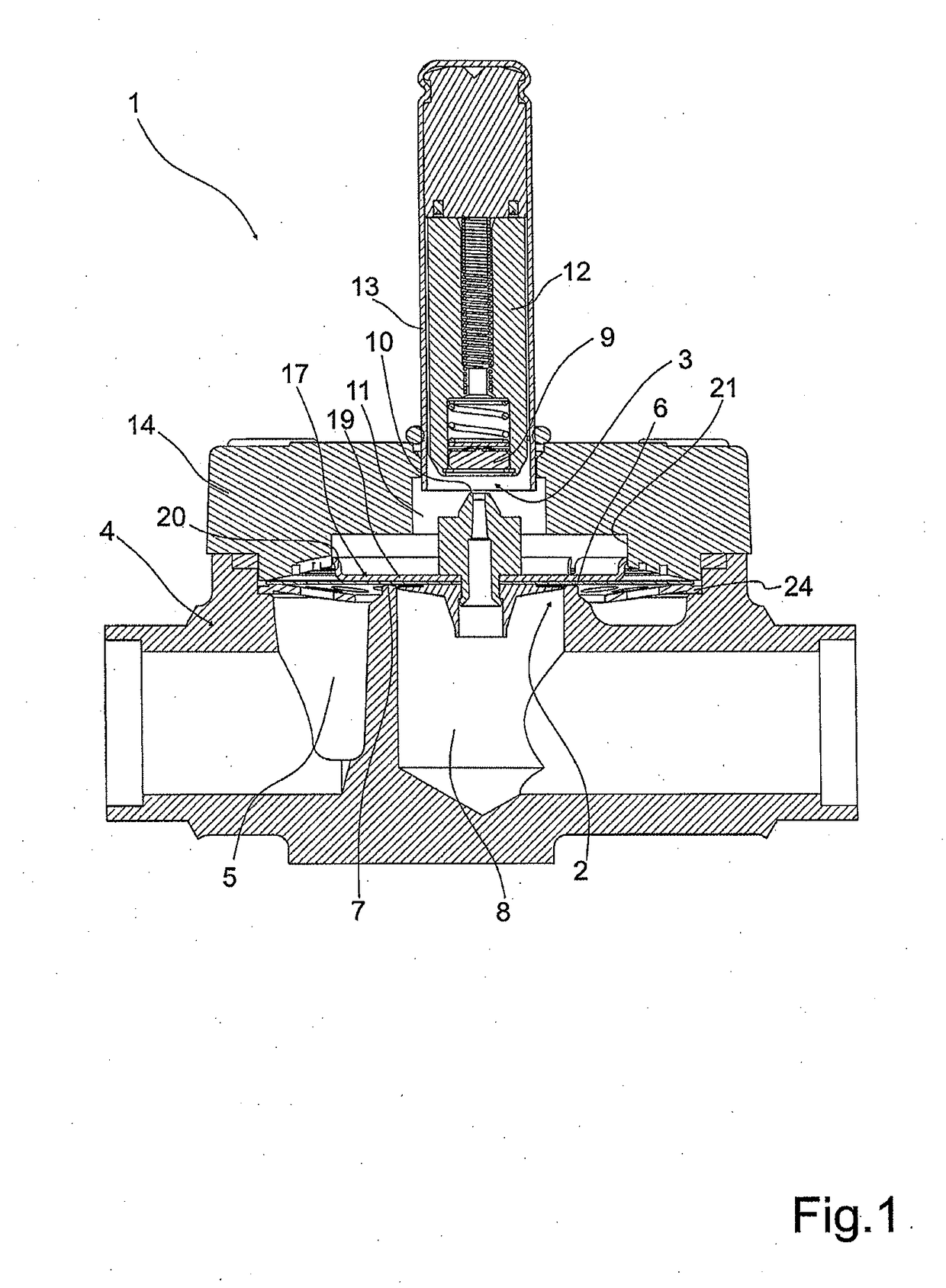

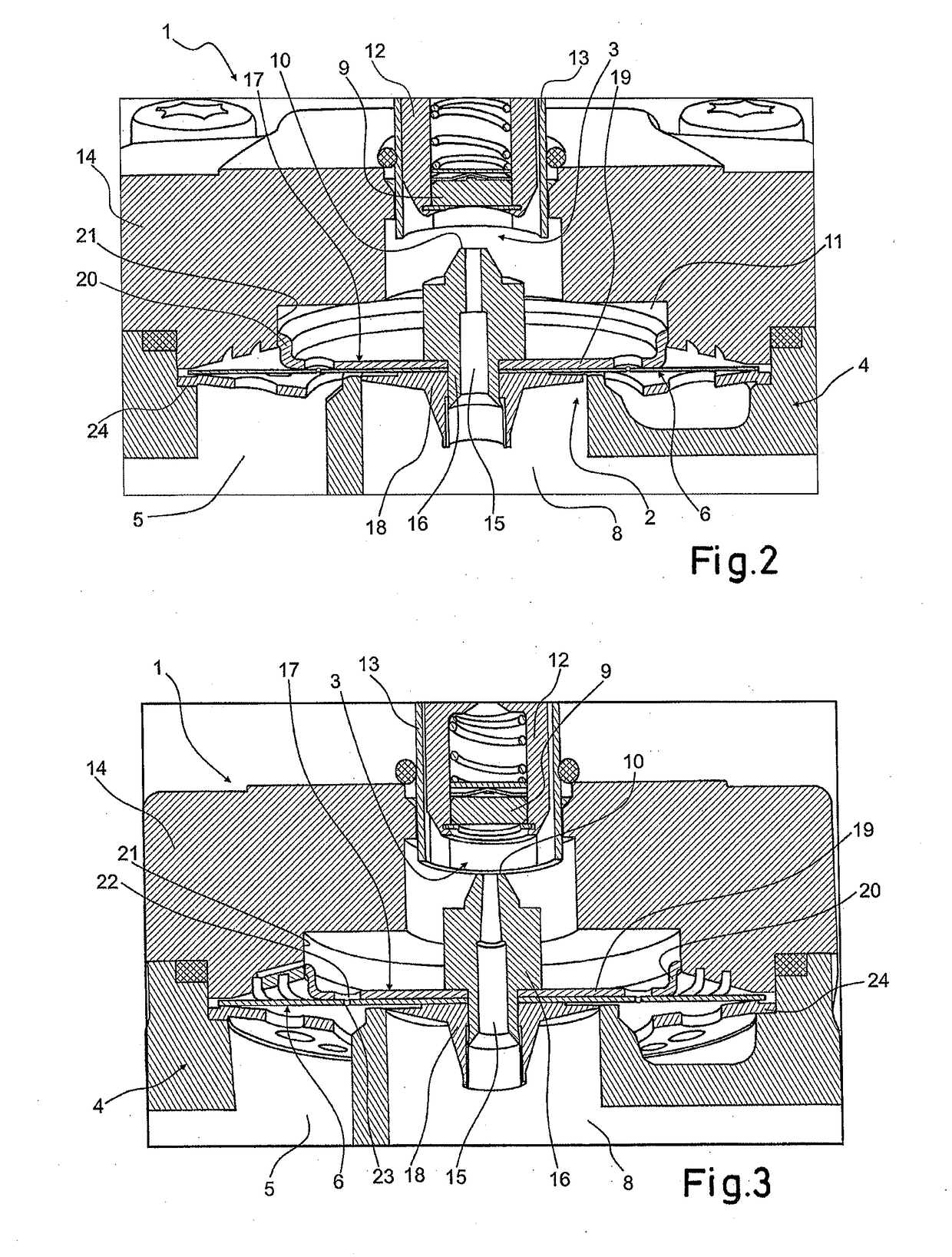

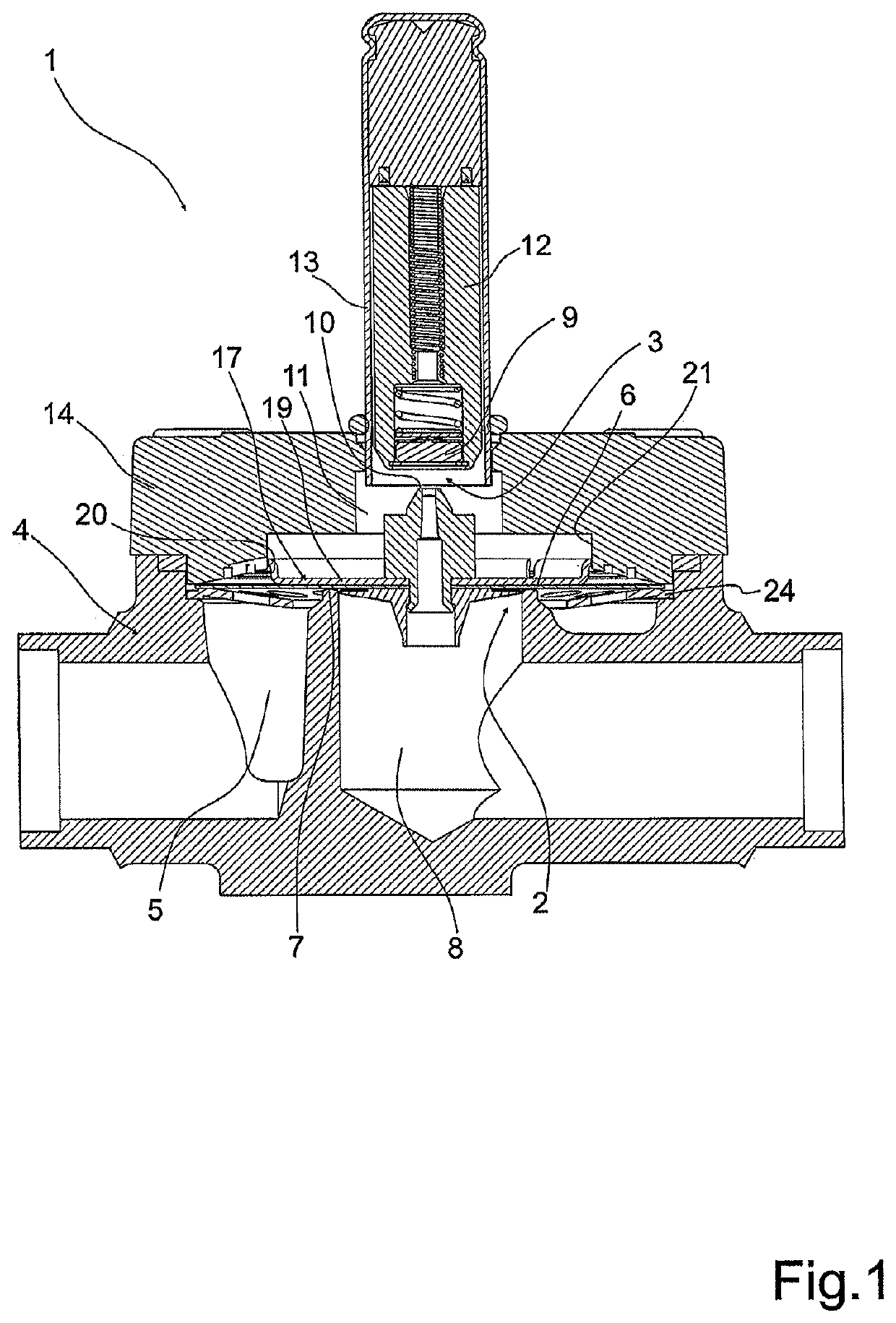

Valve

ActiveUS20180216749A1Large thermal expansionOperating means/releasing devices for valvesPilot valveEngineering

The invention relates to a valve (1) comprising a main valve (2), a pilot valve (3), a housing (4), an inlet (5) and an outlet (8). Opening and closing of the main valve (2) is controlled by the pilot valve (3). A pilot valve seat (10) is arranged in a diaphragm (6). A pilot chamber (11) is arranged in the housing (4) separated from the inlet (5) and the outlet (8) by the diaphragm (6). Task of the invention is to provide a valve with a lower cost. According to the invention a support member (17) supports the diaphragm (6), wherein the support member (17) is guided in the housing, and wherein a radial gap (26) is arranged between the radially outer end of the diaphragm (6) and the housing (4) in a radial direction perpendicular to the opening direction of the pilot valve (3). Thereby, a cheaper, less resistant material for the diaphragm can be used.

Owner:DANFOSS AS

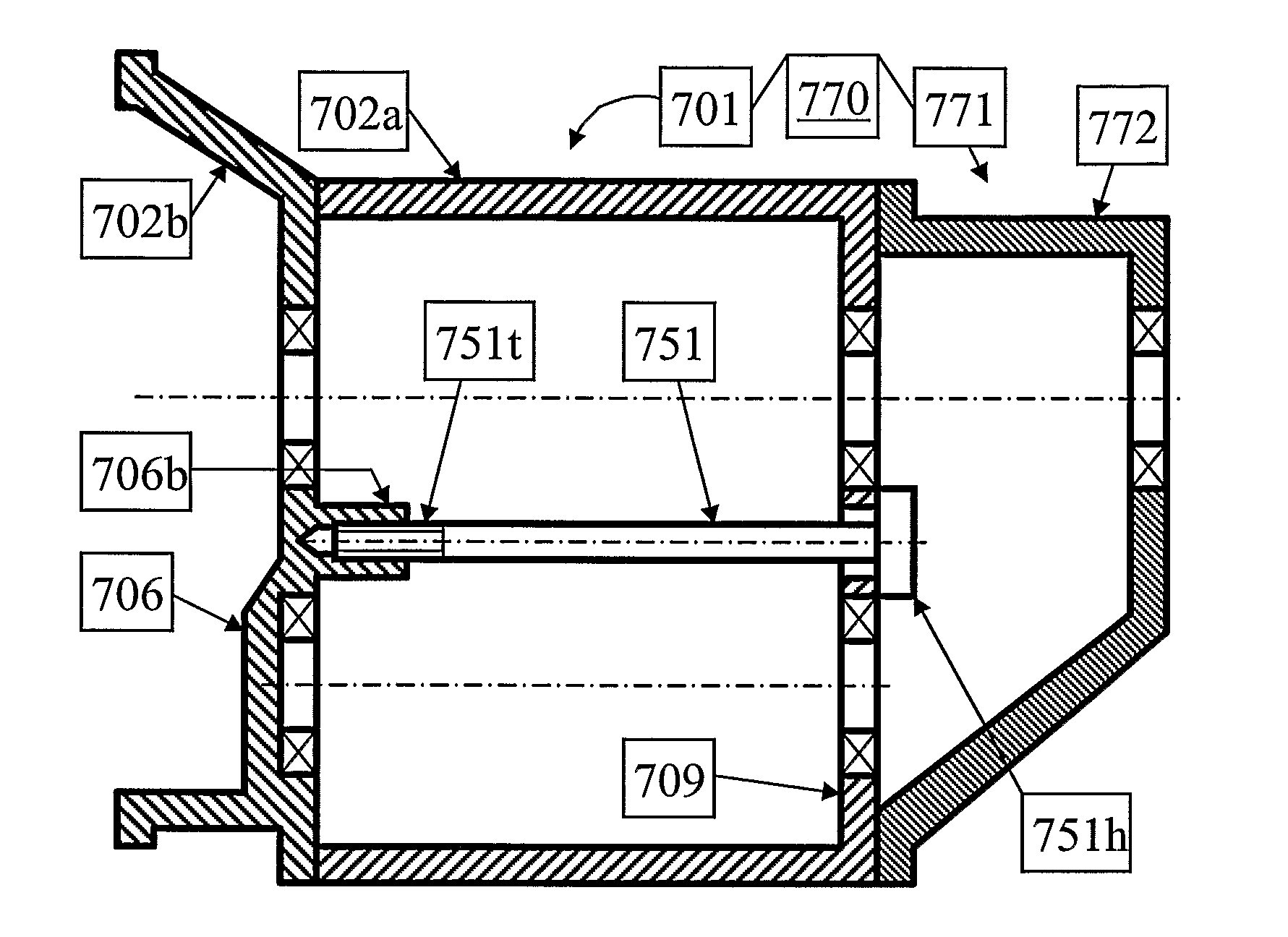

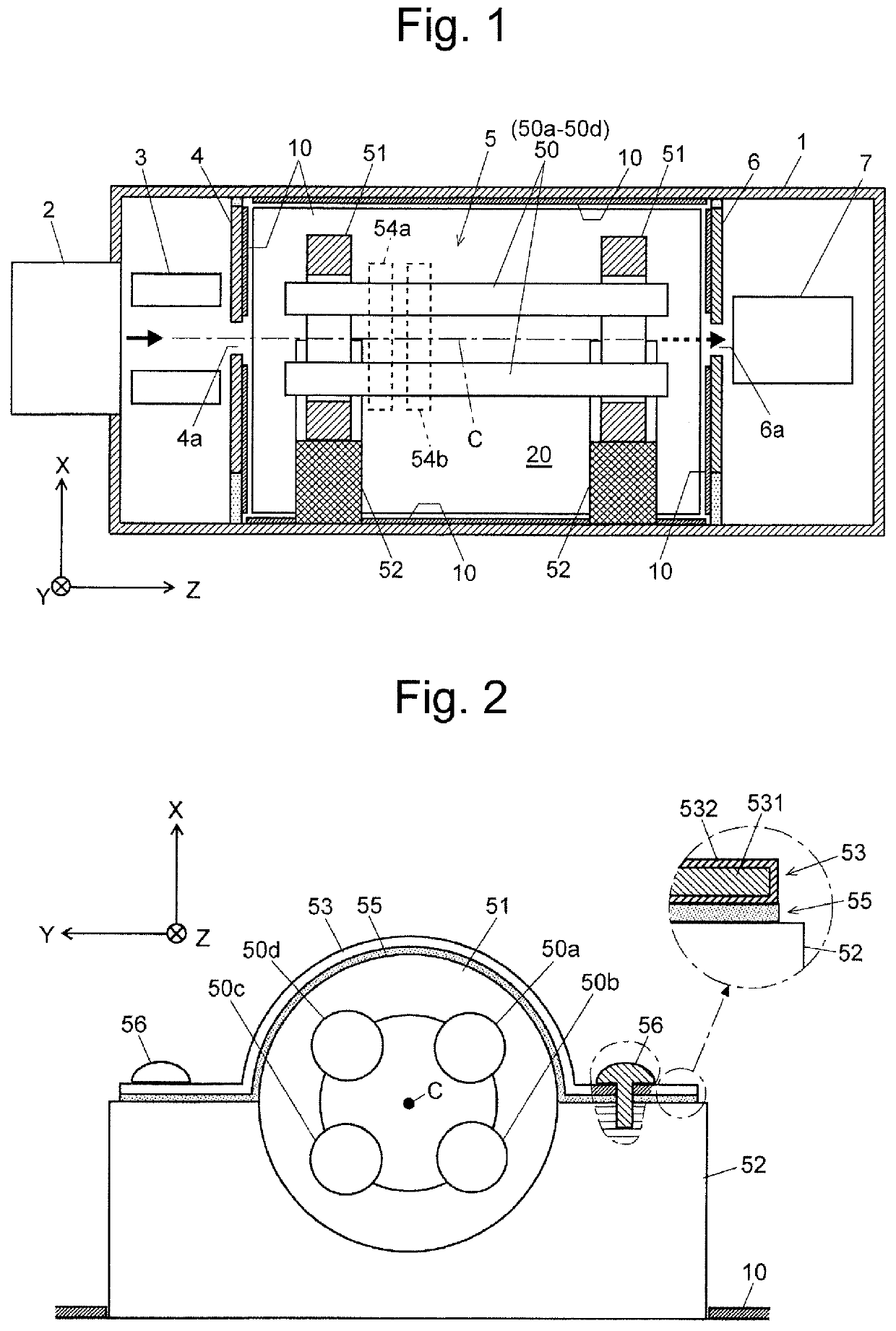

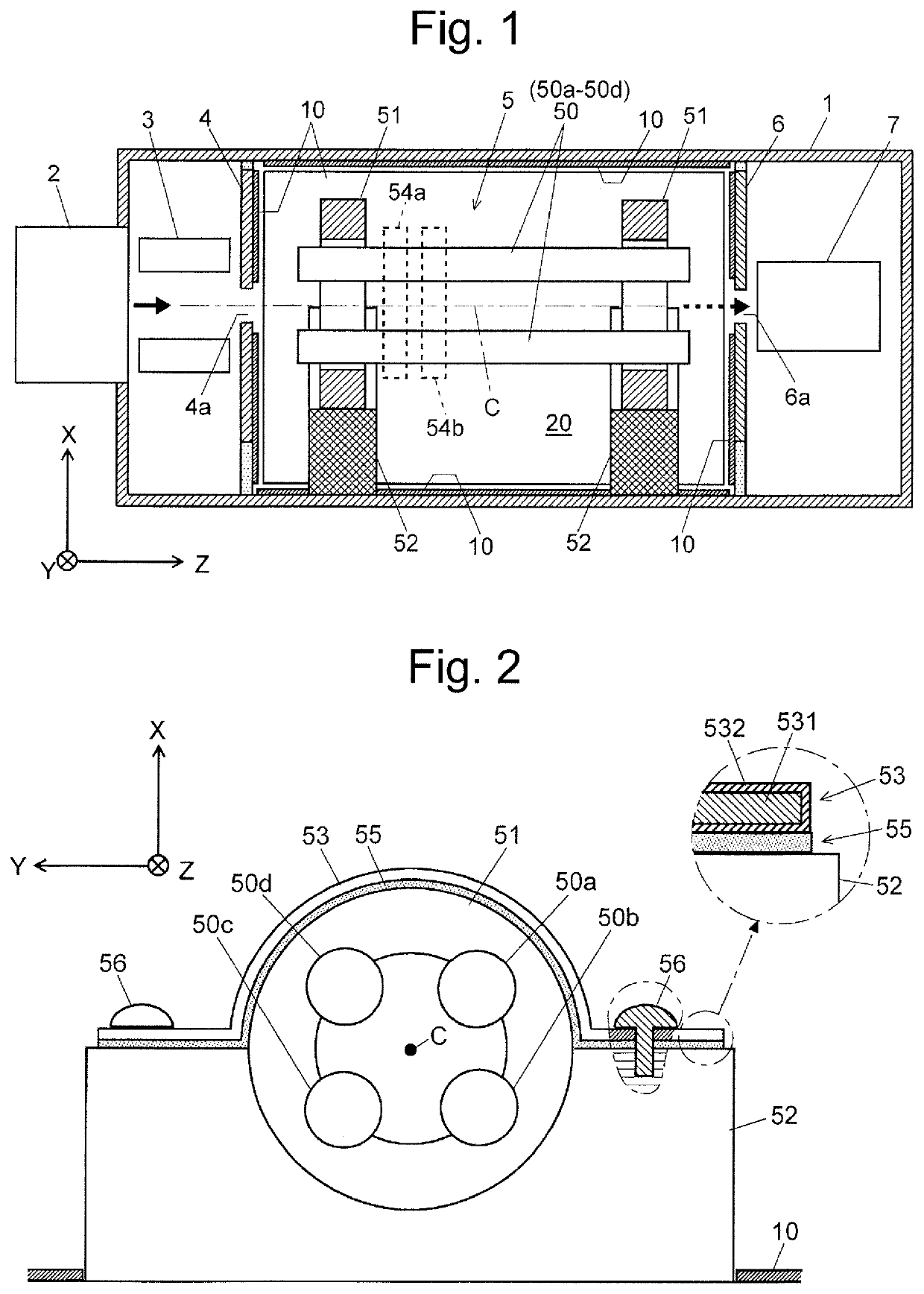

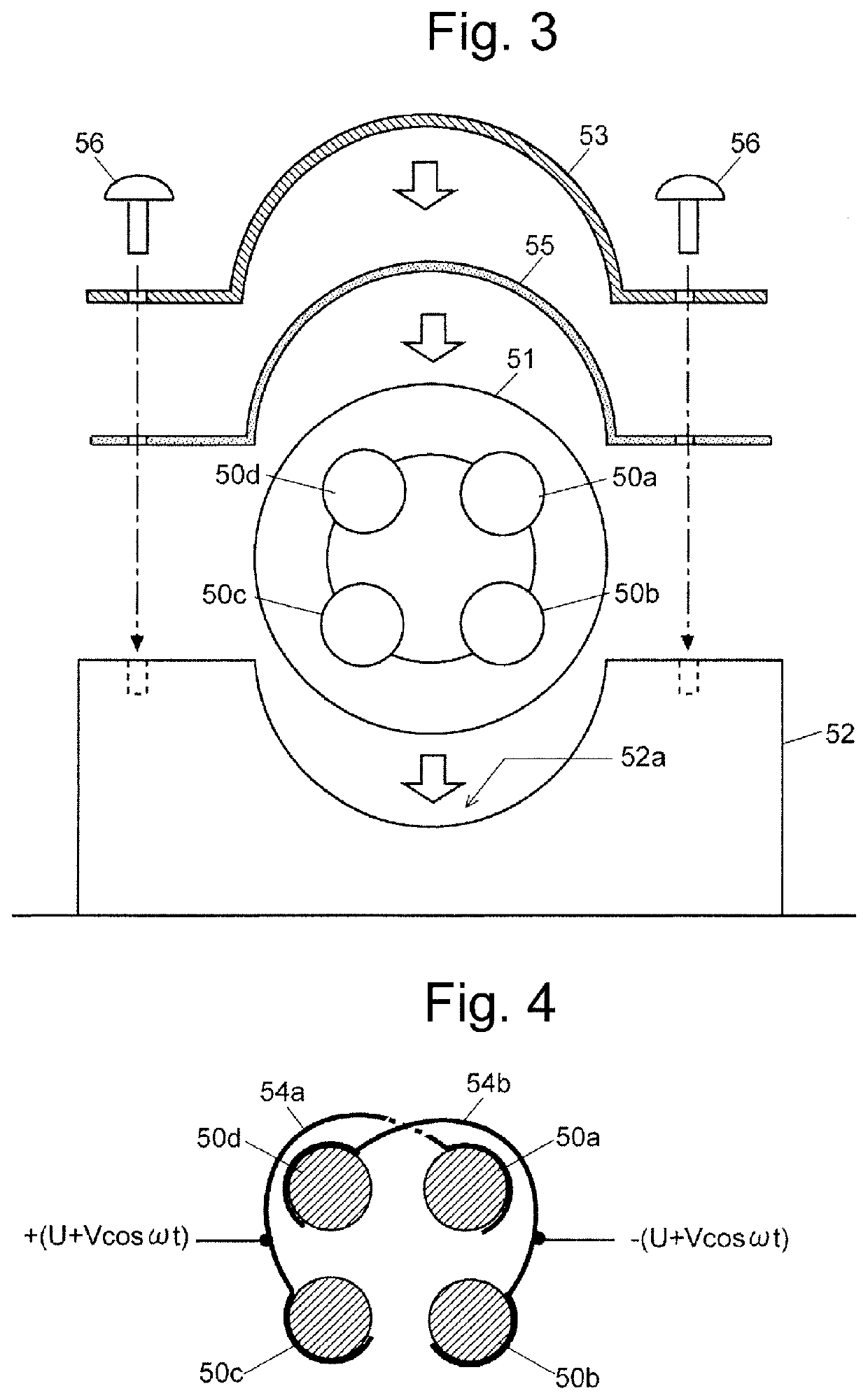

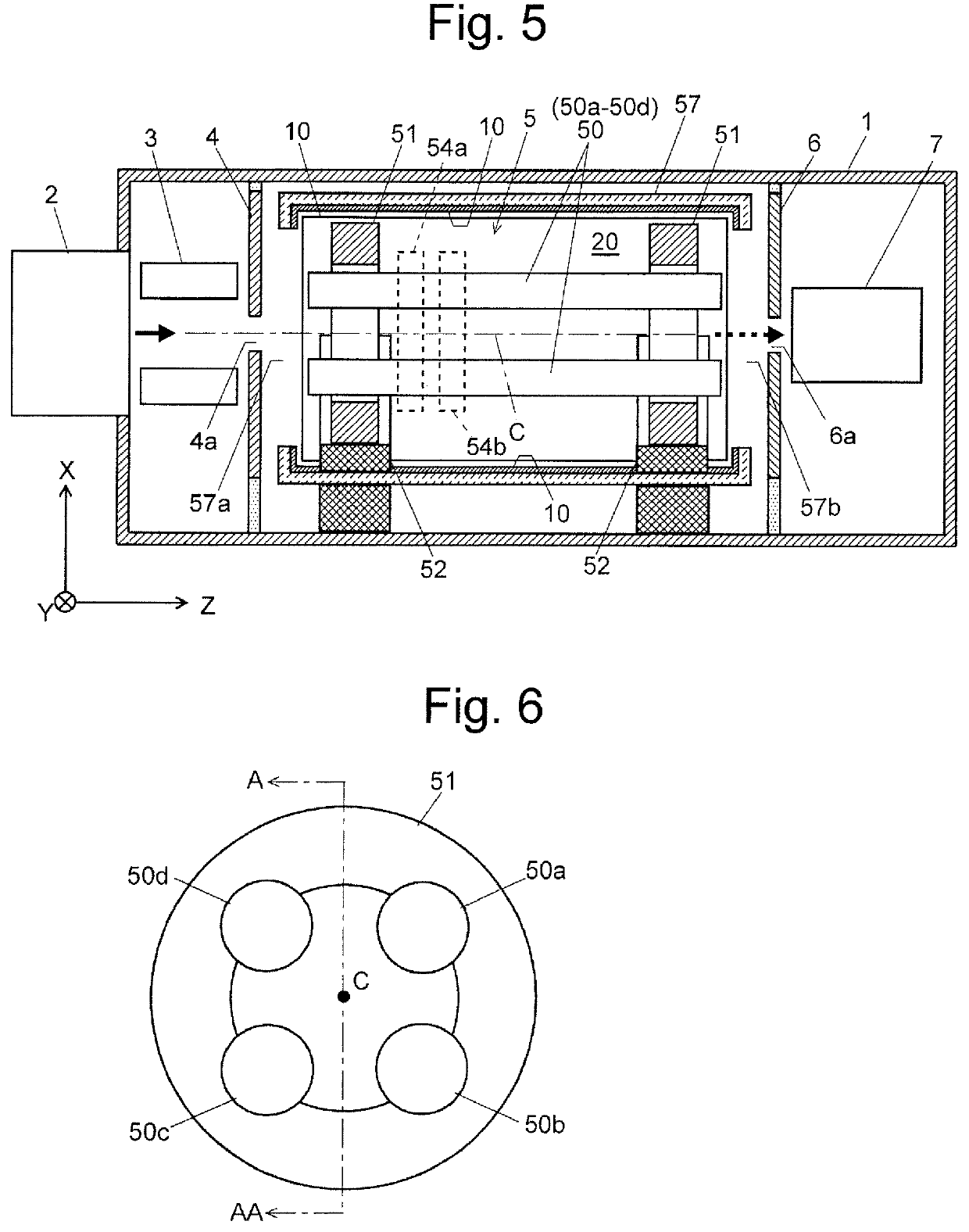

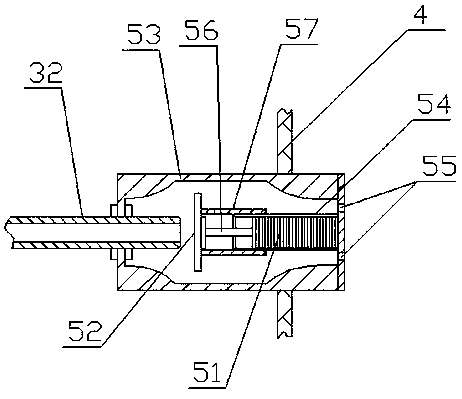

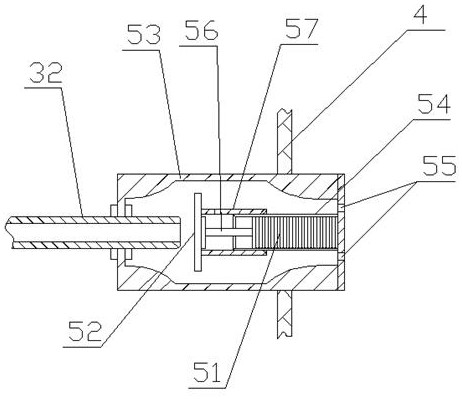

Mass spectrometer

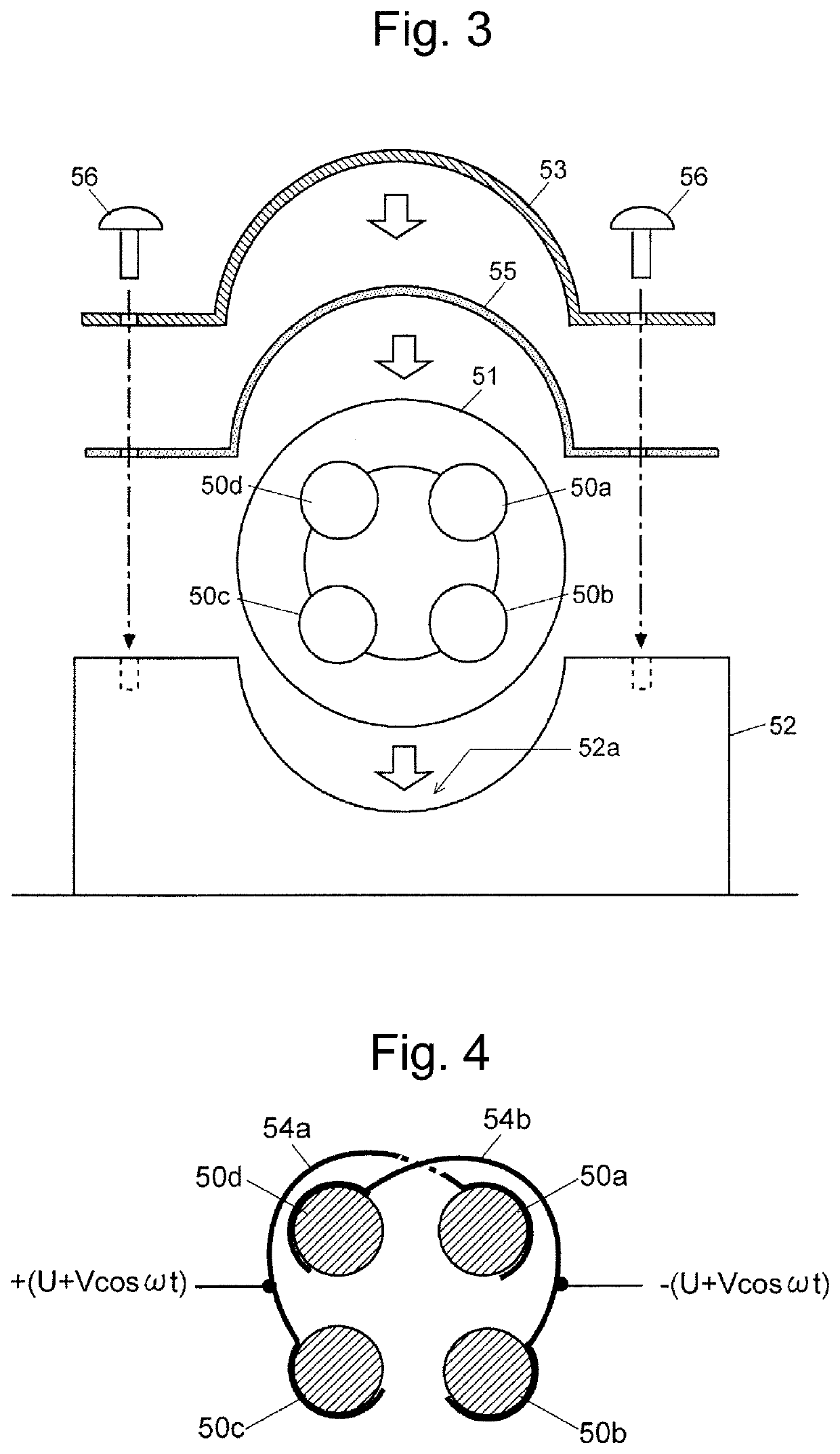

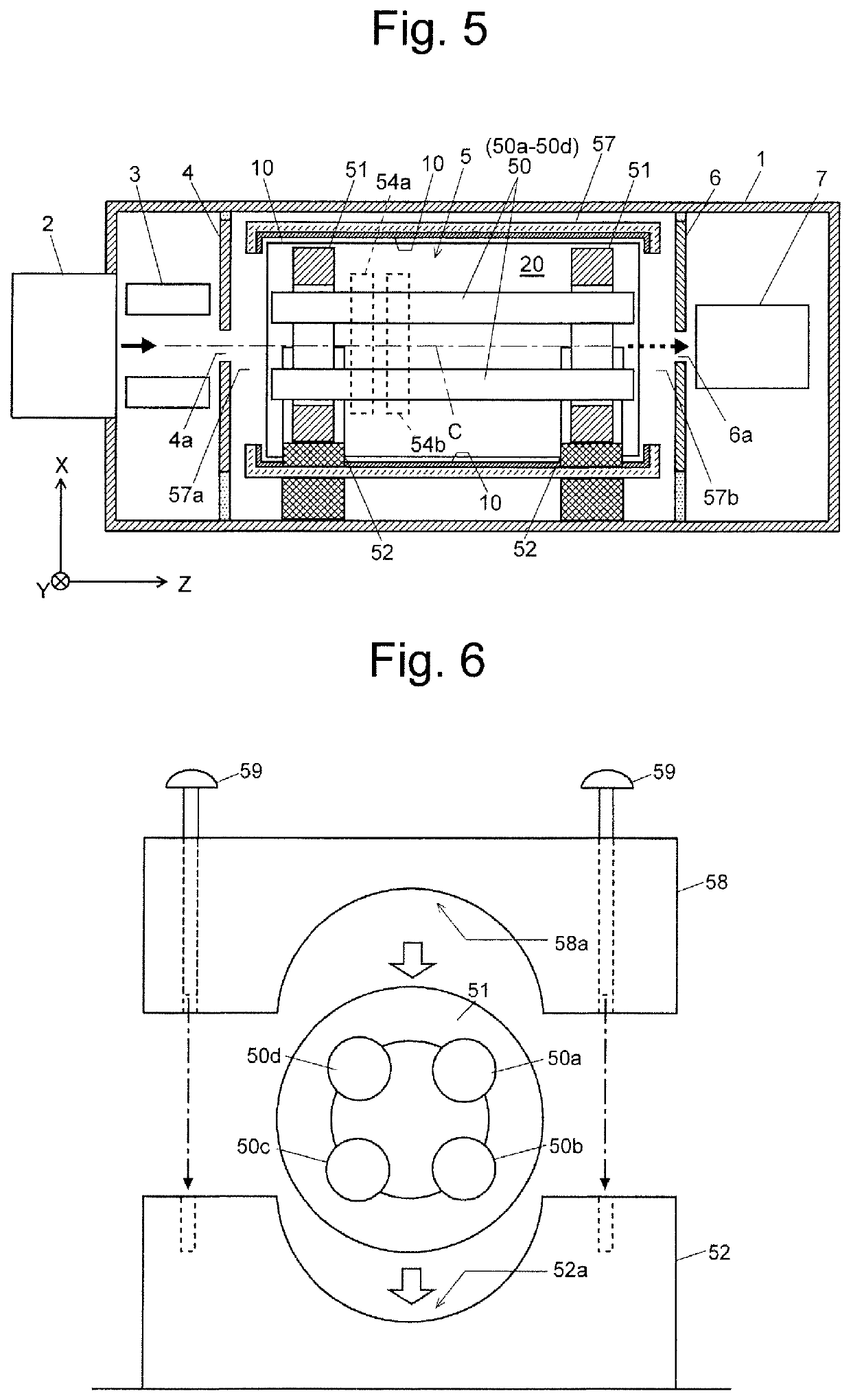

ActiveUS20200395207A1Heat releasing property is improvedReduce temperature riseStability-of-path spectrometersElectron/ion optical arrangementsPhosphor bronzeEmissivity

Four rod electrodes (50a to 50d) for separating ions according to a mass-to-charge ratio are held by a rod holder (51). The rod holder (51) is placed on a metal holder sustaining stand (52) provided on a bottom surface of a vacuum housing (1), and is fixed while being pressed by a fixation band (53) fixed to the holder sustaining stand (52) with screws (56). The fixation band (53) has a coating film layer (532) formed by a black nickel plating process on the entire surface of a main member (531) made from phosphor bronze. The coating film layer (532) has high emissivity, and thus heat transferred from the rod holder (51) to the fixation band (53) is efficiently radiated into the vacuum housing (1). Therefore, heat generated in the rod holder (51) due to dielectric loss is efficiently dissipated, and deformation of the rod holder can be reduced.

Owner:SHIMADZU CORP

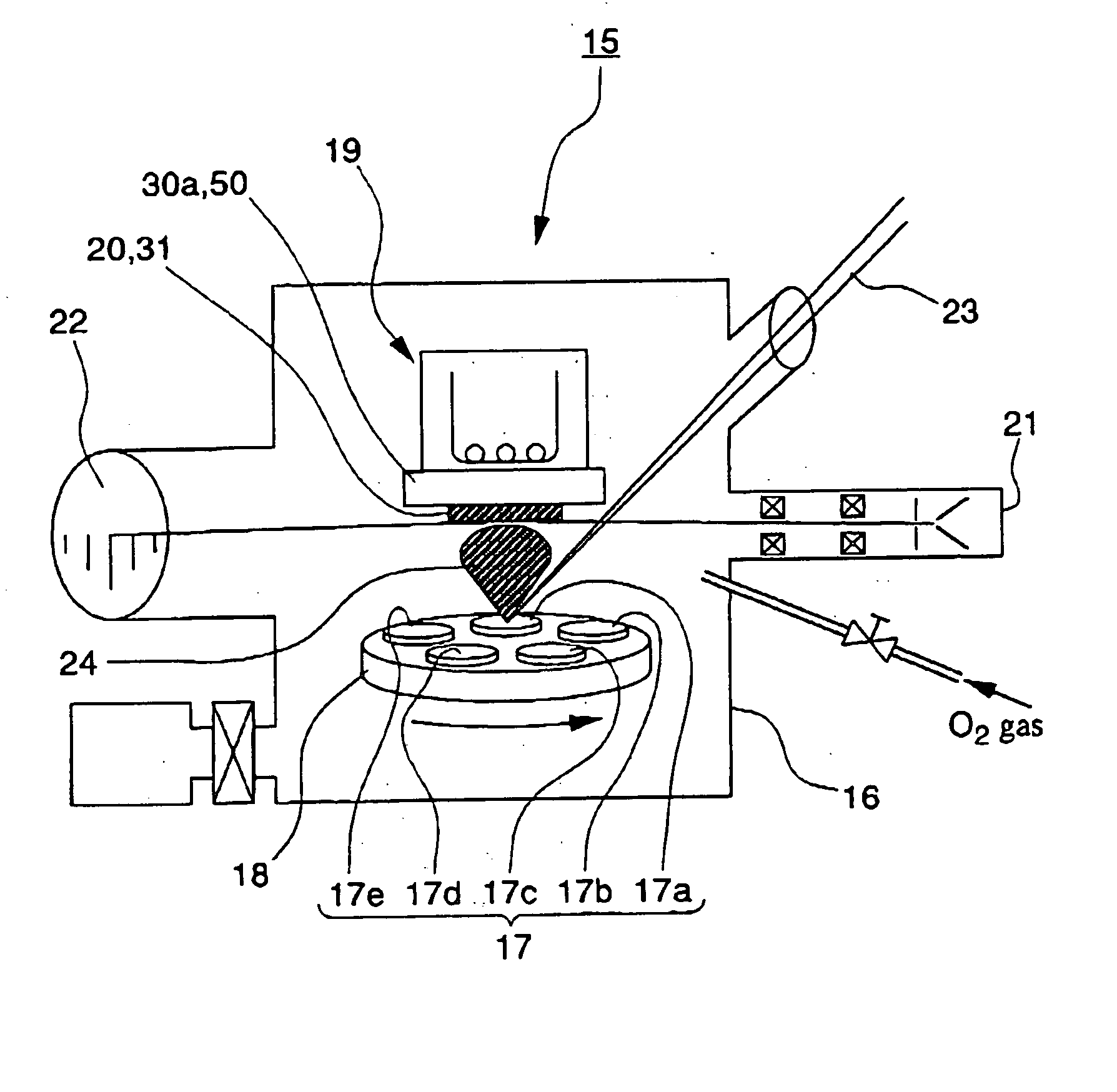

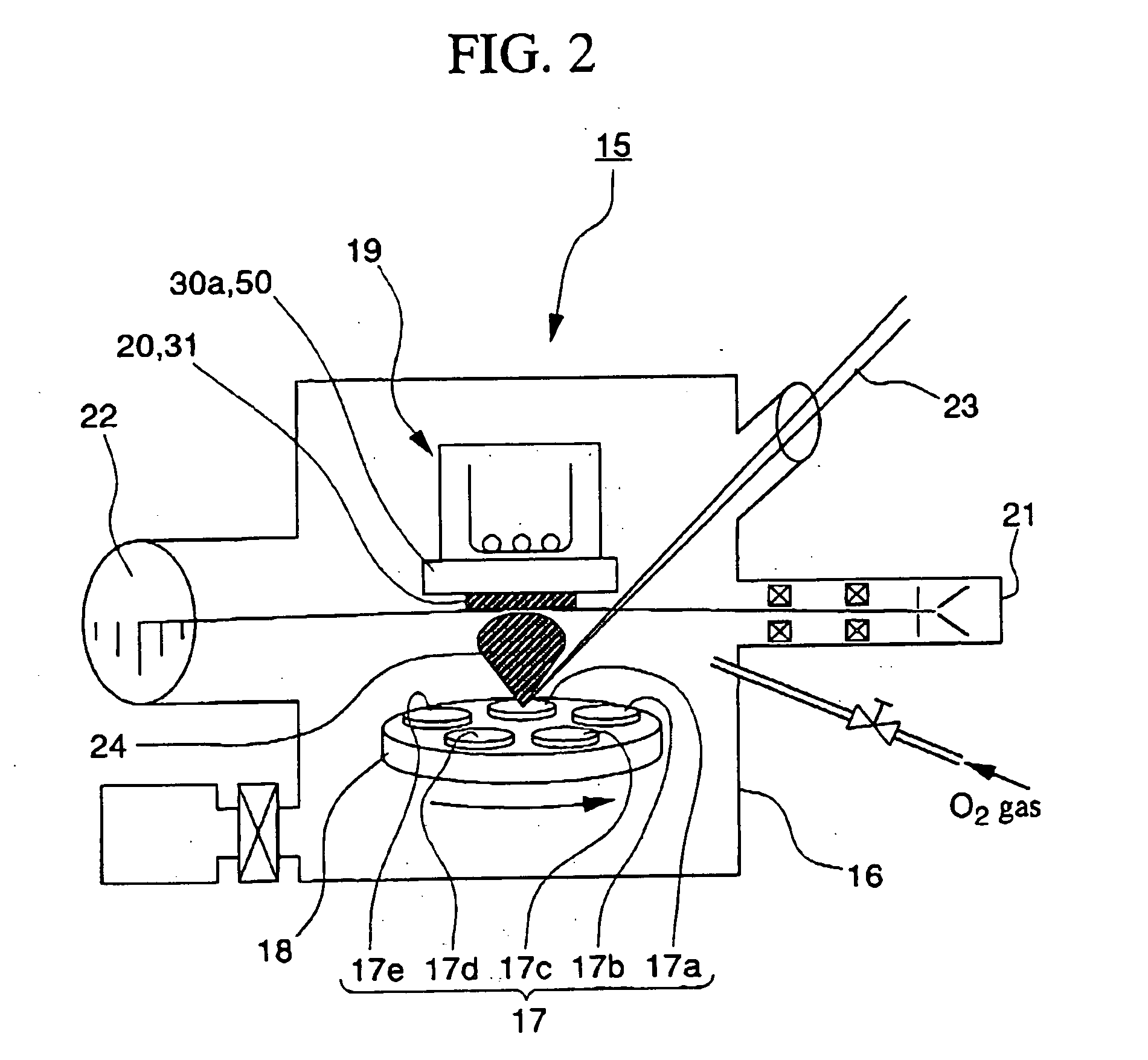

Method of manufacturing potassium niobate single crystal thin film, surface acoustic wave element, frequency filter, frequency oscillator, electronic circuit, and electronic apparatus

InactiveUS20050076829A1Save powerReduction in size power-savingPolycrystalline material growthLiquid-phase epitaxial-layer growthSingle phasePotassium niobate

A method of manufacturing KNbO3 single crystal thin film having single-phase high quality and excellent morphology on each of single crystal substrates. A surface acoustic wave element, frequency filter, frequency oscillator, electronics circuit, and electronic device employ the thin film manufactured by the method, and have high k2, and are wideband, reduced in size and economical in power consumption. A plasma plume containing K, Nb, and O in the range 0.5≦x≦xE is supplied to a substrate, where x is a mole ratio of niobium (Nb) to potassium (K) in KxNb1-xOy, and xE is a mole composition ratio at the eutectic point for KNbO3 and 3K2O.Nb2O5 under a predetermined oxygen partial pressure. Maintaining the temperature Ts of the substrate in the range TE≦Ts≦Tm where TE represents the temperature at the eutectic point and Tm represents a complete melting temperature, the KNbO3 single crystal is precipitated from the KxNb1-xOy deposited on the substrate.

Owner:SEIKO EPSON CORP

Production method for metal castings

InactiveCN106001414AImprove mechanical propertiesImprove the lubrication effectFoundry mouldsFoundry coresIntermediate frequencyCastability

A production method of metal castings. The invention relates to a production process of metal castings. Firstly, a clay core is set in a mold, and plane splitting is adopted, upper and lower boxes are used to make it, and a bottom injection leak bag is poured into the mold by an intermediate frequency alkaline induction furnace. The raw materials for smelting, after removing the sprue riser, take out the casting, and then heat treat the casting. The invention has good high-temperature strength, small deformation, small thermal cracking tendency, excellent corrosion resistance, and especially better casting performance than the original material.

Owner:无锡市华东电力设备有限公司

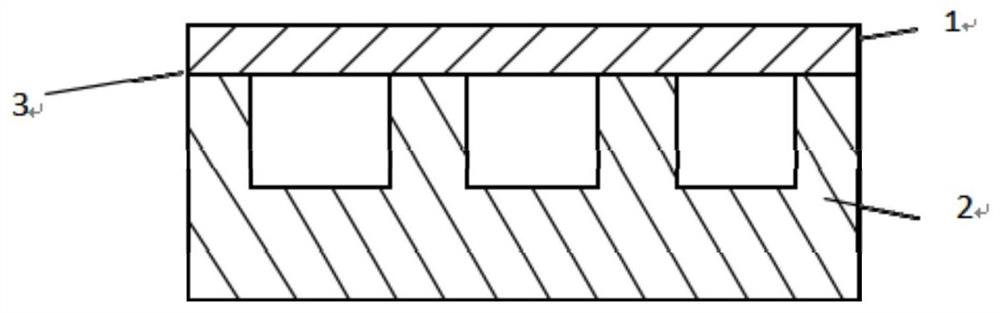

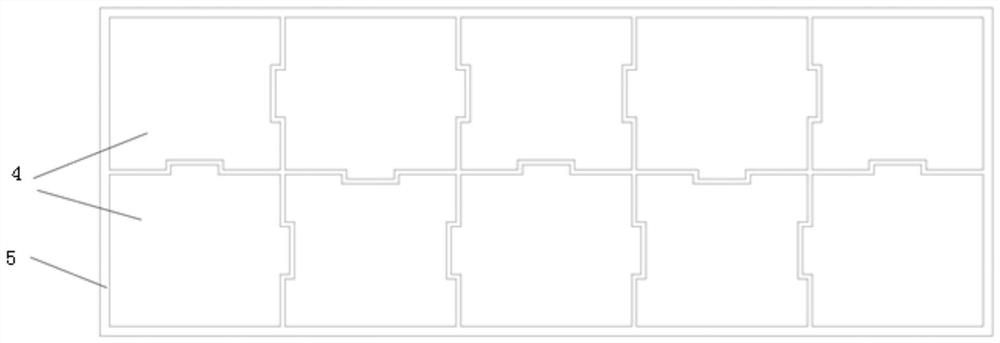

Base aiming at aluminum alloy cold plate brazing

ActiveCN108941837AReduce deformation effectsLow thermal expansionWelding/soldering/cutting articlesSoldering auxillary devicesCold plateFriction force

The invention relates to a base aiming at aluminum alloy cold plate brazing. The base is characterized in that the base comprises base plates (4) and a supporting plate (5), and the multiple base plates (4) are arranged on the supporting plate (5) at intervals; and during welding, an upper cover plate (1) and a lower bottom plate (2) of an aluminum alloy cold plate are placed on the base and thenplaced into a stainless steel tool frame, fastening force is applied, and then welding is carried out. The base has the advantages that according to the overall technological path, a base plate used in a traditional method for aluminum alloy cold plate brazing is broken up into parts, the form of multiple base plates are arranged is designed, the influence of friction plate of the base plates andthe lower bottom plate of the cold plate on brazing is reduced, and brazing quality is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Piston for a cylinder for an internal combustion engine

ActiveUS10801439B2Equally distributedIncrease pressureMolten spray coatingInternal combustion piston enginesCombustion chamberInternal combustion engine

A piston for a cylinder for an internal combustion engine has a piston bowl surface adapted for facing a combustion chamber of the cylinder, the piston bowl surface being provided with a thermal barrier coating layer, wherein the thermal barrier coating layer is provided on a plurality of circumferentially spaced surface parts of the piston bowl surface. A method for producing a piston for a cylinder for an internal combustion engine includes the steps of providing a piston for a cylinder for an internal combustion engine, the piston having a piston bowl surface adapted for facing a combustion chamber of the cylinder, and providing the piston bowl surface with a thermal barrier coating layer, wherein the step of providing the thermal barrier coating layer is made on a plurality of circumferentially spaced surface parts of the piston bowl surface.

Owner:VOLVO TRUCK CORP

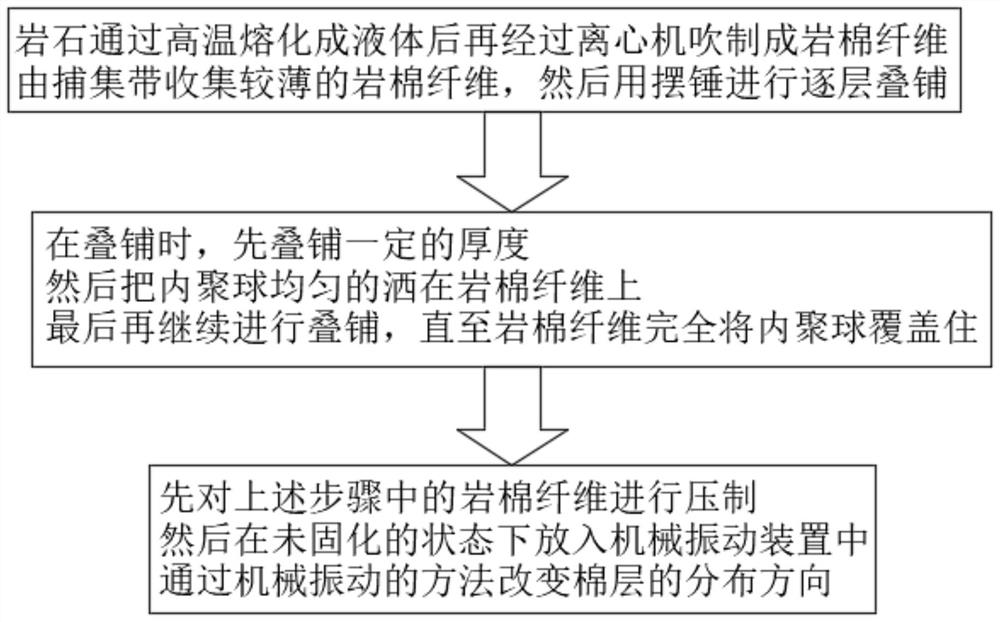

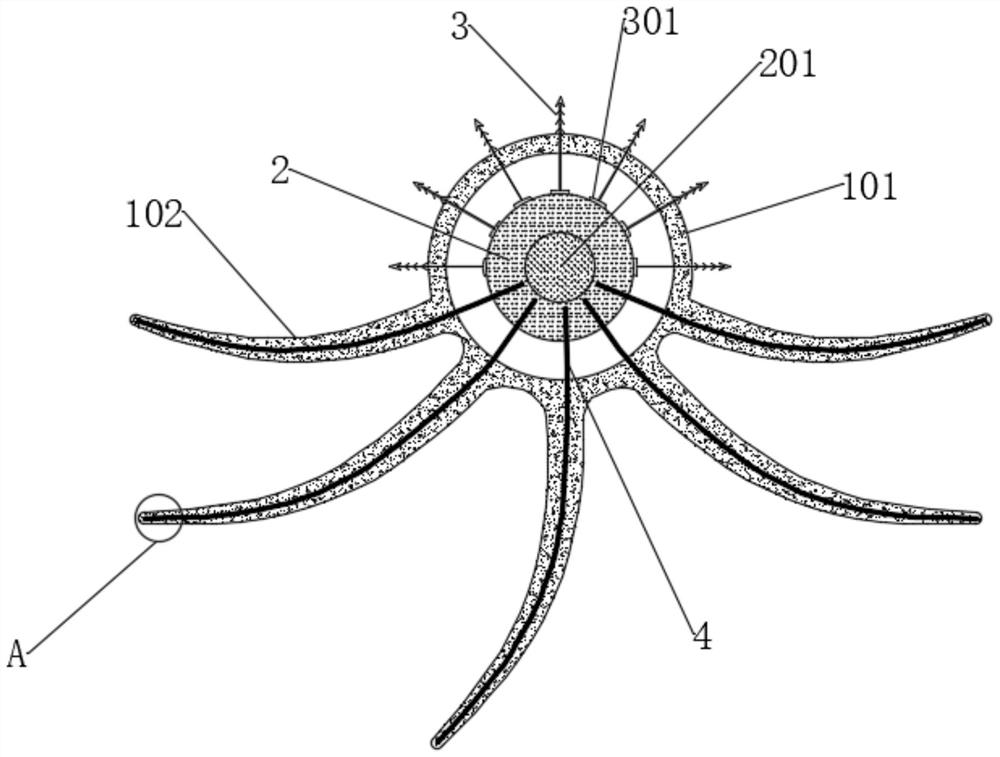

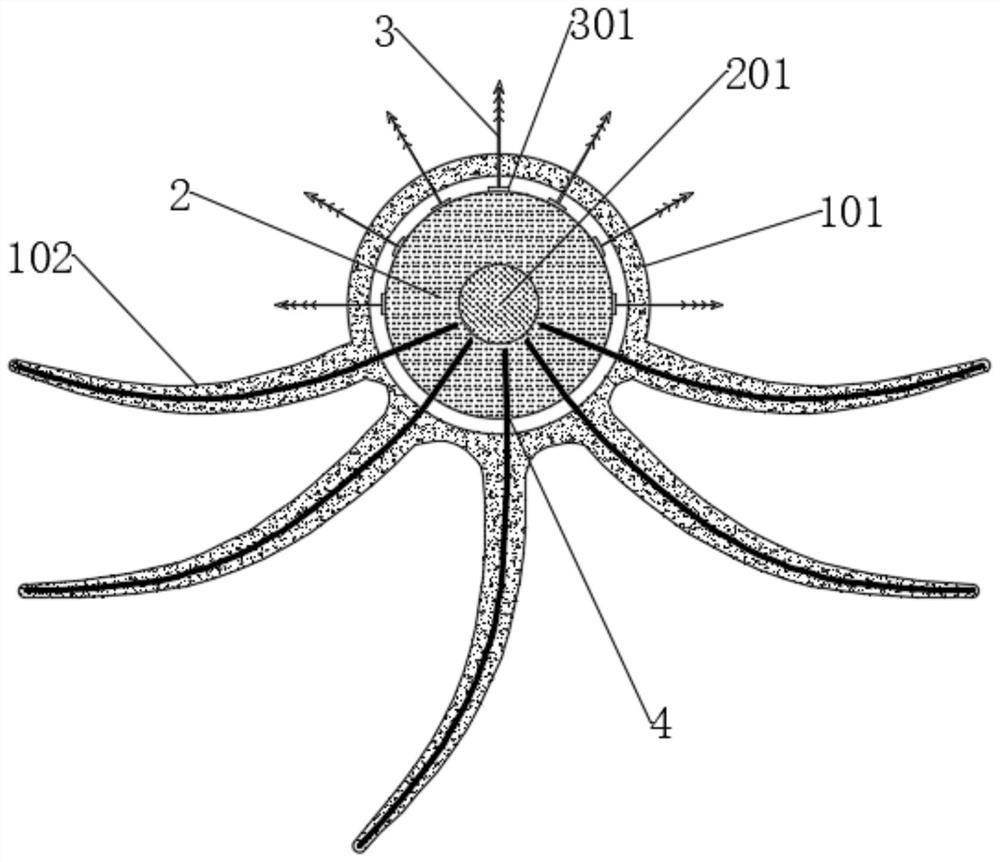

Preparation method of high-strength waterproof rock wool board

ActiveCN113263788AImprove waterproof performanceHigh strengthLamination ancillary operationsLaminationCotton fibrePolymer chemistry

The invention discloses a preparation method of a high-strength waterproof rock wool board, and belongs to the field of rock wool boards; a cohesion ball is creatively added in the process of producing the rock wool board by using the existing three-dimensional method to improve the cohesion of the rock wool board; on one hand, after the cohesion ball absorbs the heat of rock wool fibers, a pushing ball is expanded to push out a puncture rod, and the puncture rod penetrates through a plurality of layers of rock wool fibers to increase the cohesion of the rock wool fibers; on the other hand, the heat enables a heat shrinkage wrapping film to shrink so as to extrude a hydrophobic agent, the missing part can be filled with the hydrophobic agent to cover, the waterproof performance is effectively improved, the appearance of the cohesion ball is similar to the shape of octopus, a plurality of tentacles drag surrounding rock wool fibers, the strength of the rock wool board is effectively improved, and the rock wool board is prevented from cracking and falling off.

Owner:桥水(黑龙江)建筑材料科技有限责任公司

Mass spectrometer

ActiveUS20210175066A1Improve propertiesReduce temperature riseStability-of-path spectrometersElectron/ion optical arrangementsMass analyzerMechanical engineering

Four rod electrodes (50a to 50d) for separating ions according to a mass-to-charge ratio are held by a rod holder (51). The rod holder (51) is placed on a metal holder sustaining stand (52) provided on a bottom surface of a vacuum housing (1), and is fixed while being pressed by a fixation band (53) fixed to the holder sustaining stand (52) with screws (56). The fixation band (53) is made from phosphor bronze having higher thermal conductivity than thermal conductivity of stainless steel or the like. Therefore, heat generated in the rod holder (51) due to dielectric loss is not only directly transmitted to the holder sustaining stand (52), but also efficiently transmitted to the holder sustaining stand (52) through the fixation band (53). With this, the heat of the rod holder (51) is efficiently dissipated, and non-uniformity of temperature of the rod holder can be reduced.

Owner:SHIMADZU CORP

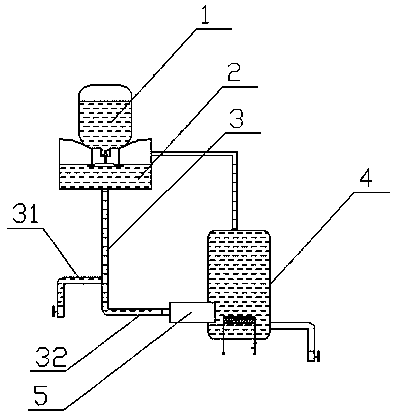

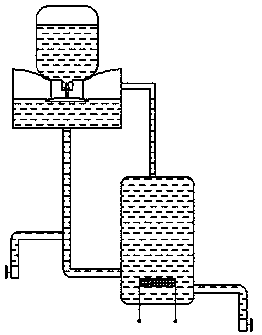

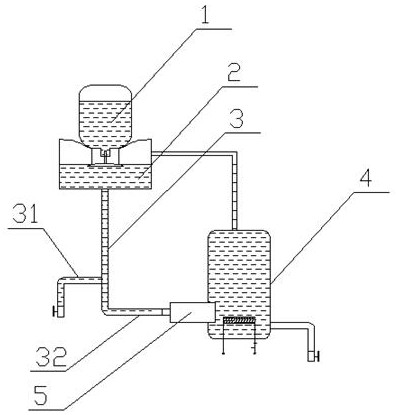

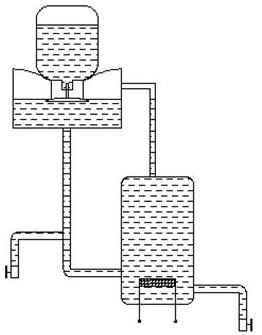

Water dispenser

InactiveCN109770716APrevent liquid level from getting too lowPrevent backflowBeverage vesselsEngineeringWater tanks

The invention relates to a water dispenser. The water dispenser comprises a bucket, a cold water tank, a water outlet pipe and a hot water tank, wherein the upper end of the cold water tank is provided with a smart seat internally provided with a smart head, and the bucket is connected to the cold water tank through the smart seat; the lower portion of the cold water tank is connected to the upperend of the water outlet pipe; the lower portion of the water outlet pipe forks to form two branch pipes, namely the first branch pipe and the second branch pipe, and the first branch pipe is connected with a water outlet valve to form a cold water outlet; the second branch pipe is connected with the hot water tank to supply cold water to the hot water tank; the side wall of the hot water tank isconnected with a hot water outlet pipe; the second branch pipe is connected with the hot water tank through a hot water reflux prevention unit, the hot water reflux prevention unit is internally provided with a heating expansion element, the heating expansion element is connected with a valve plate, and the valve plate is opposite to a port of the second branch pipe; the heating expansion elementis heated to expand to drive the valve plate to move to the port of the second branch pipe, thereby blocking the port of the second branch pipe, so that the second branch pipe is disconnected with thehot water tank to avoid the situation that hot water flows back into the cold water tank.

Owner:陈洛斌

A base for brazing aluminum alloy cold plate

ActiveCN108941837BReduce deformation effectsLow thermal expansionWelding/soldering/cutting articlesSoldering auxillary devicesSS - Stainless steelFriction force

The invention relates to a base for brazing of an aluminum alloy cold plate, which is characterized in that: the base includes a base plate (4) and a support plate (5), and several base plates (4) are arranged at intervals on the support plate ( 5) above; when welding, place the upper cover plate (1) and lower base plate (2) of the aluminum alloy cold plate on the base, then put the stainless steel tooling frame and apply the tightening force, and then weld . The advantage of the present invention is that the overall technical path is to divide the base plate used in the traditional method of aluminum alloy cold plate brazing into parts, and design it into a form of multi-piece arrangement, so as to reduce the friction between the base plate and the lower bottom plate of the cold plate. The influence of welding can improve the quality of brazing.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

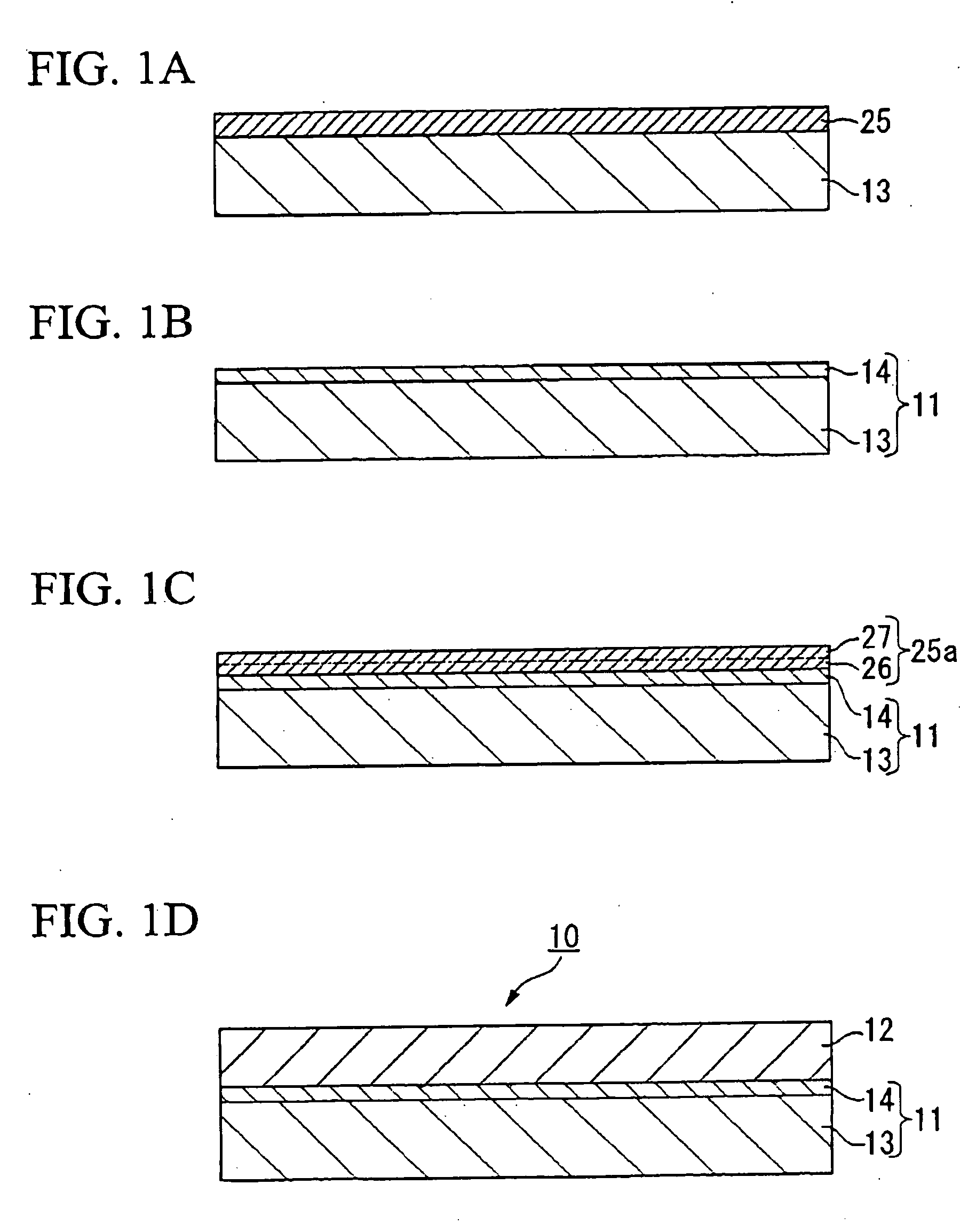

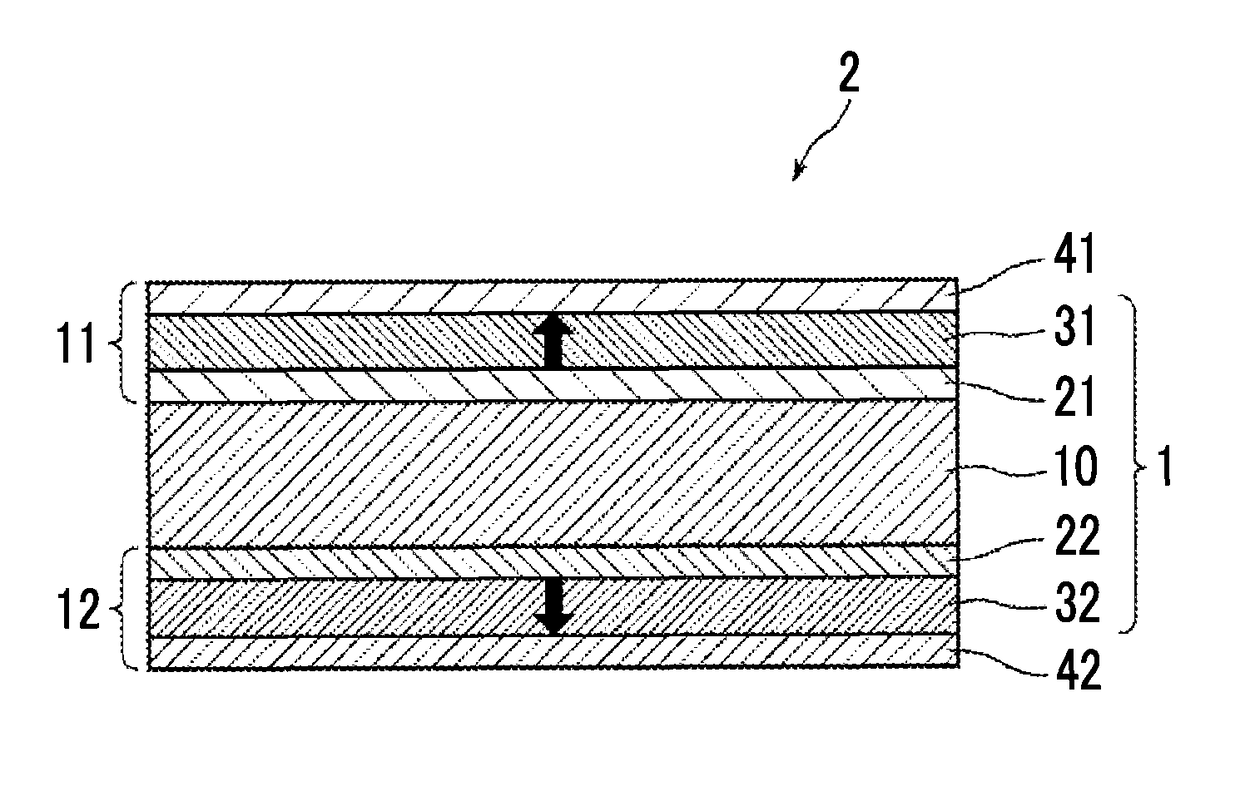

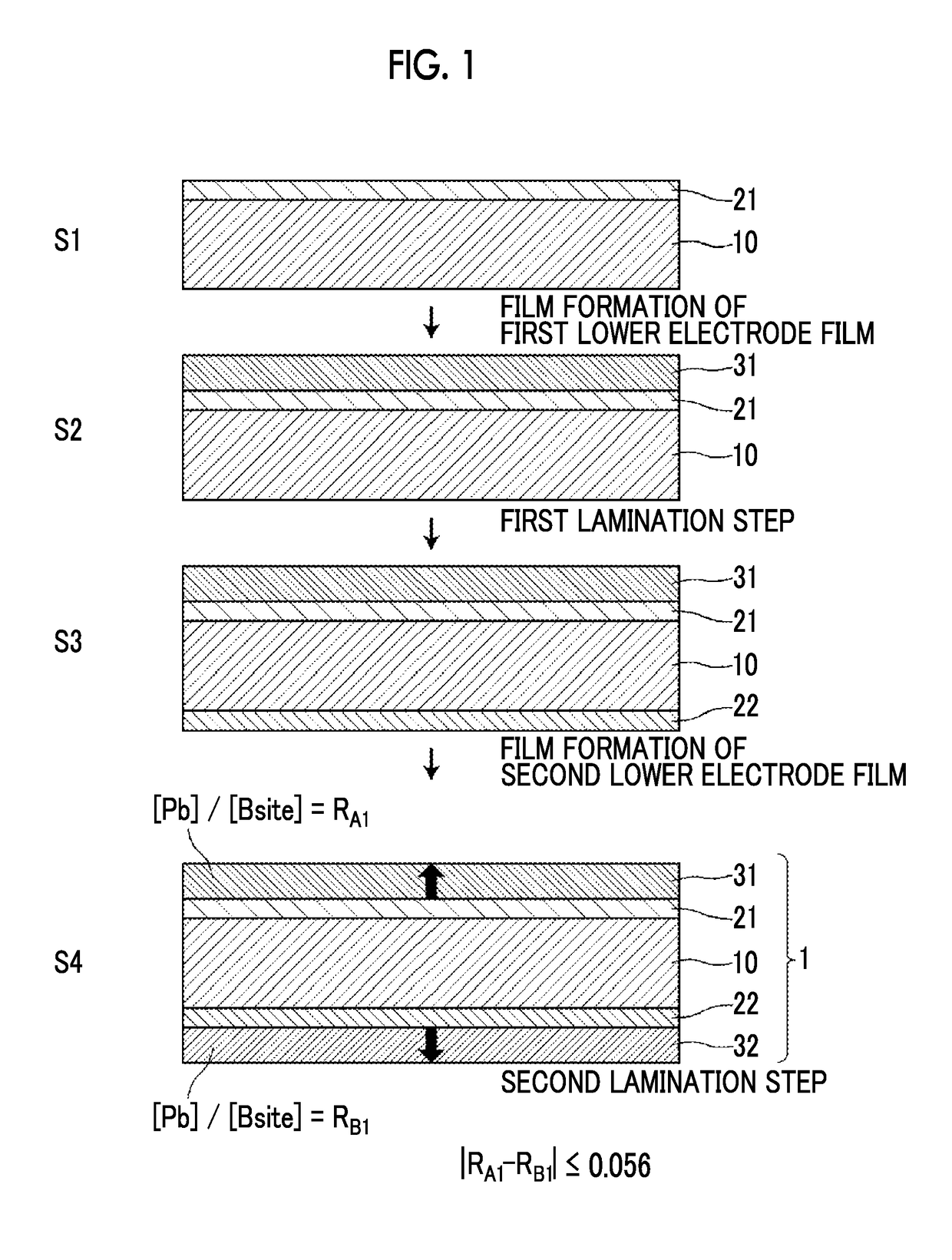

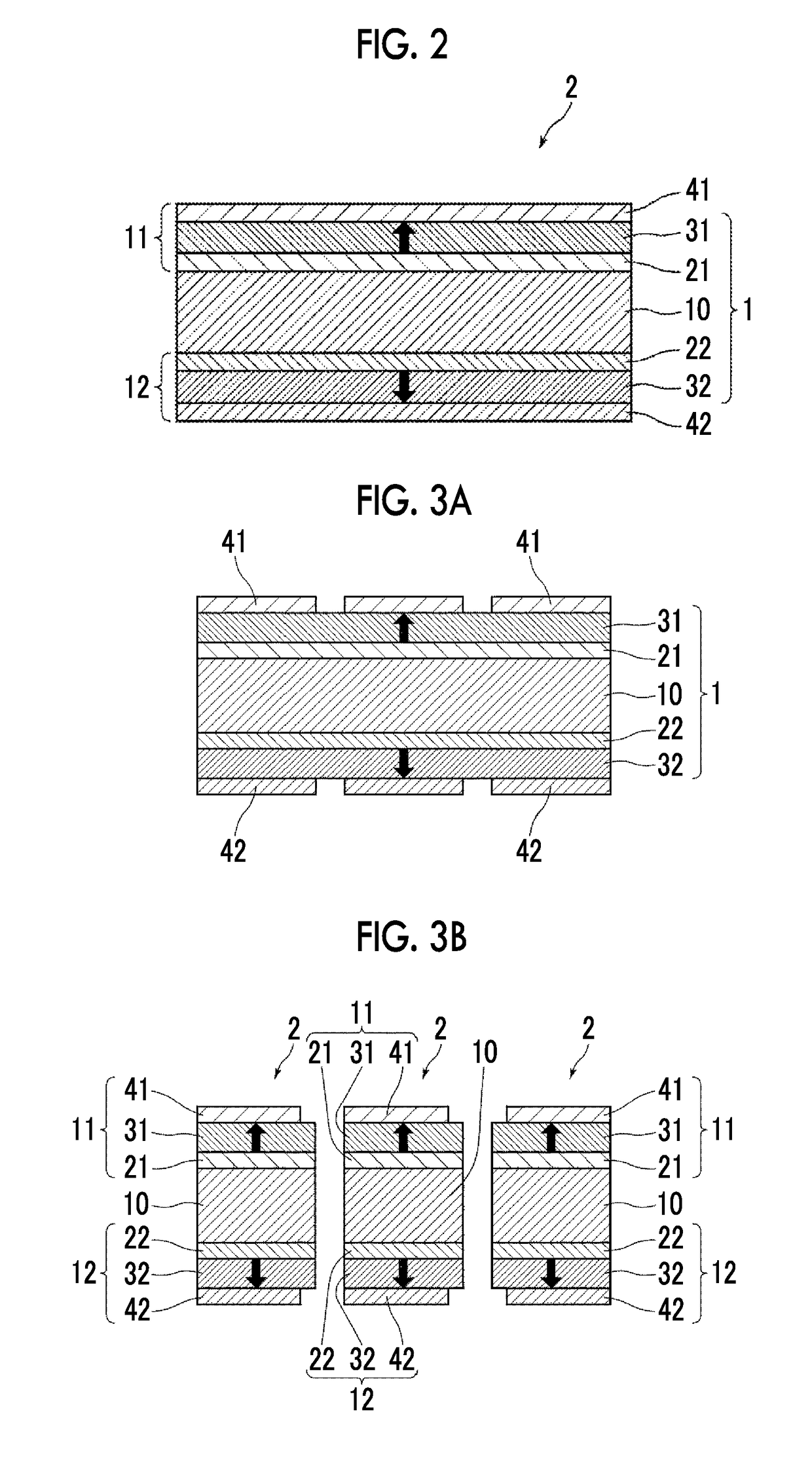

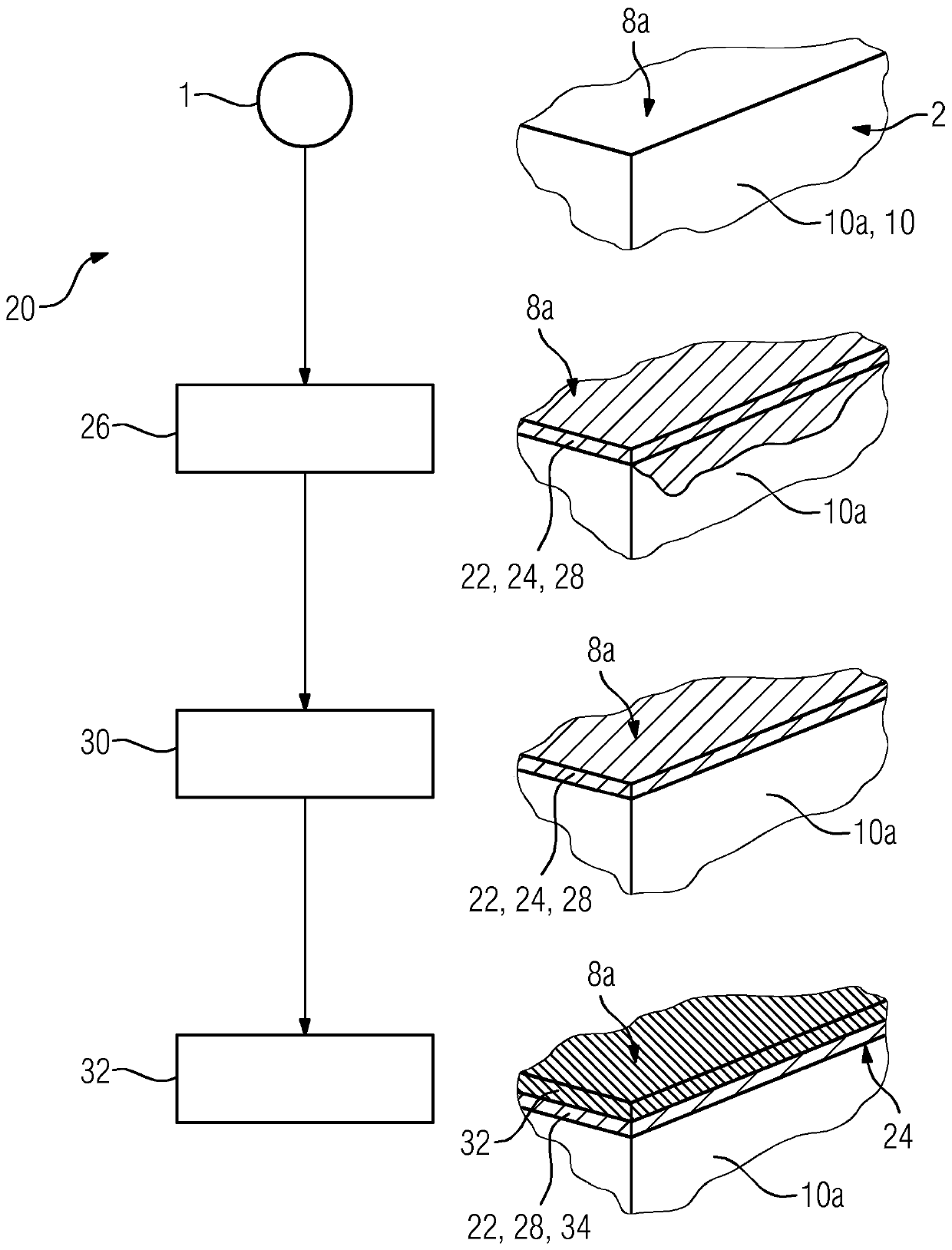

Method of producing laminated thin film structure, laminated thin film structure, and piezoelectric element including same

ActiveUS10020443B2Improve featuresLarge thermal expansionMechanical vibrations separationPiezoelectric/electrostrictive devicesEngineeringThermal expansion

A first lamination step of forming lower electrode films on both surfaces of a diaphragm and directly forming a first Pb-containing perovskite oxide film which has a larger thermal expansion coefficient than that of the diaphragm and has a columnar structure on a front surface of the lower electrode film; and a second lamination step of directly forming a second Pb-containing perovskite oxide film on a front surface of the lower electrode film are sequentially performed. The second Pb-containing perovskite oxide film is formed under a condition that a difference between a molar ratio RA1 of Pb to a B-site element in the first Pb-containing perovskite oxide film and a molar ratio RB1 of Pb to a B-site element in the second Pb-containing perovskite oxide film after the second lamination step is 0.056 or less.

Owner:FUJIFILM CORP

a water dispenser

InactiveCN109770716BPrevent backflowAvoid the phenomenon of low liquid levelBeverage vesselsEngineeringEnvironmental engineering

The invention relates to a water dispenser, comprising a bucket, a cold water tank, a water outlet pipe and a hot water tank. A smart seat with a built-in smart head is arranged at the upper end of the cold water tank, and the water bucket is connected to the cold water tank through the smart seat; The upper end of the outlet pipe is connected; the lower branch of the outlet pipe forms two branches, namely the first branch and the second branch. The first branch is connected to the water outlet valve to form a cold water outlet; the second branch is connected to the hot water tank, Cold water is supplied in the water tank; the side wall of the hot water tank is connected with a hot water outlet pipe; the second branch is connected to the hot water tank through a hot water backflow prevention unit, and the hot water backflow prevention unit has a built-in thermal expansion element, which is connected to the A valve plate, the valve plate is opposite to the port of the second branch; when the heated expansion element is heated, the expansion drives the valve plate to move towards the port of the second branch, thereby blocking the port of the second branch, so that the second branch Disconnect from the hot water tank to avoid backflow of hot water into the cold water tank.

Owner:陈洛斌

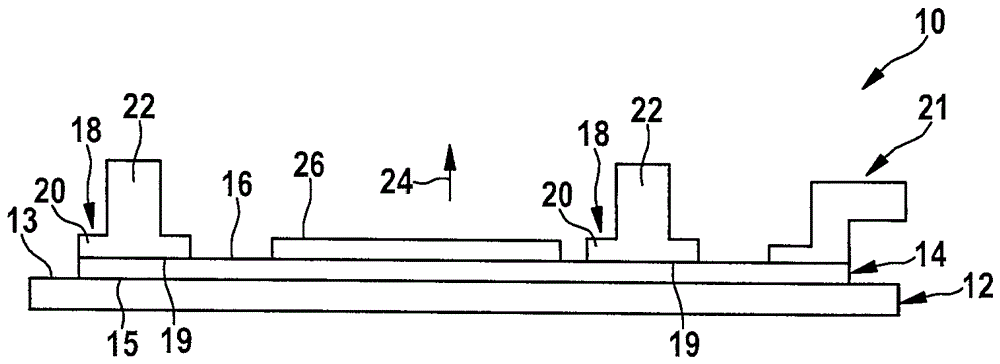

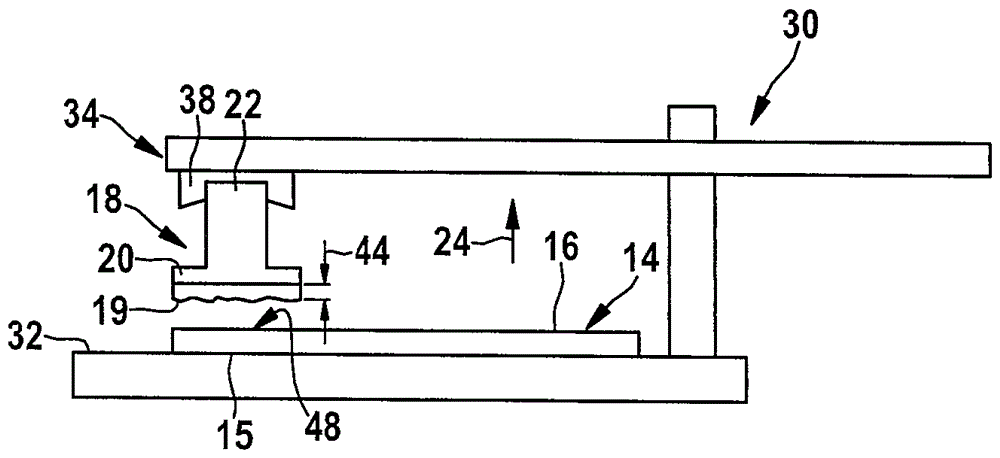

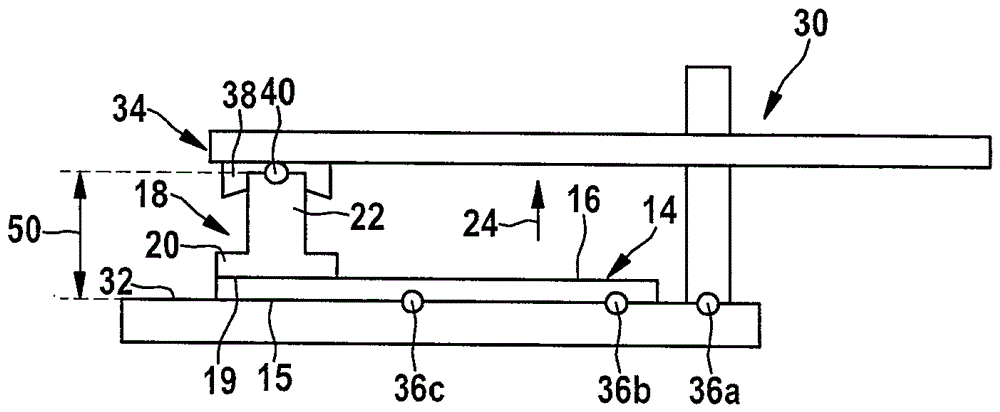

Method for producing an electronic module in particular for a motor vehicle transmission control unit

InactiveCN106605456AFlexible placementFlexible designPrinted circuit assemblingCasings with connectors and PCBComputer moduleEngineering

A method for producing an electronic module (10) is proposed in which a sensor element (18) having a mounting device (30) is attached to an external surface (16) of a printed circuit board element (14), wherein the sensor element (18) has a sensor area (22) and a base area (20) that can be plasticized at least in sections. The method is characterized in particular in that the base area (20) is plasticized up to a plasticization length (44) that is measured from the base surface (19) of the sensor element (18) in a z direction (24); the plasticized base area (20) and the external surface (16) of the printed circuit board element (14) are joined together such that the sensor area (22) is arranged with a defined positioning accuracy at a target distance (50) to a reference point (36a) which is fixed relative to the external surface (16), and the plasticized base area (20) is subsequently solidified, wherein the positioning accuracy is smaller than the plasticization length (44). As a result of this, the sensor area (22) can be arranged with accuracy at the target distance (50) independently of the component tolerance of the printed circuit board element (14) and / or of the sensor element (18), which accuracy is exclusively determined by the mounting device (30).

Owner:ROBERT BOSCH GMBH

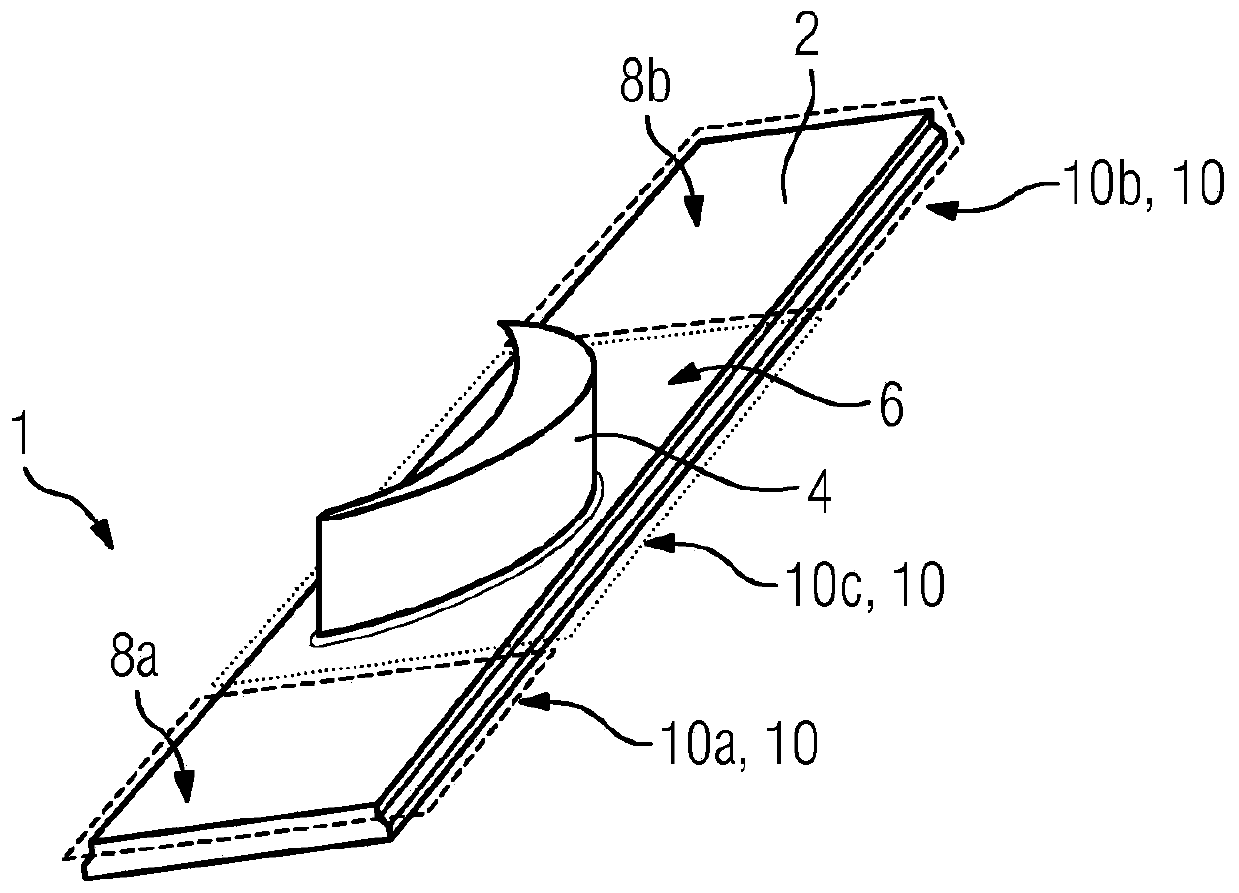

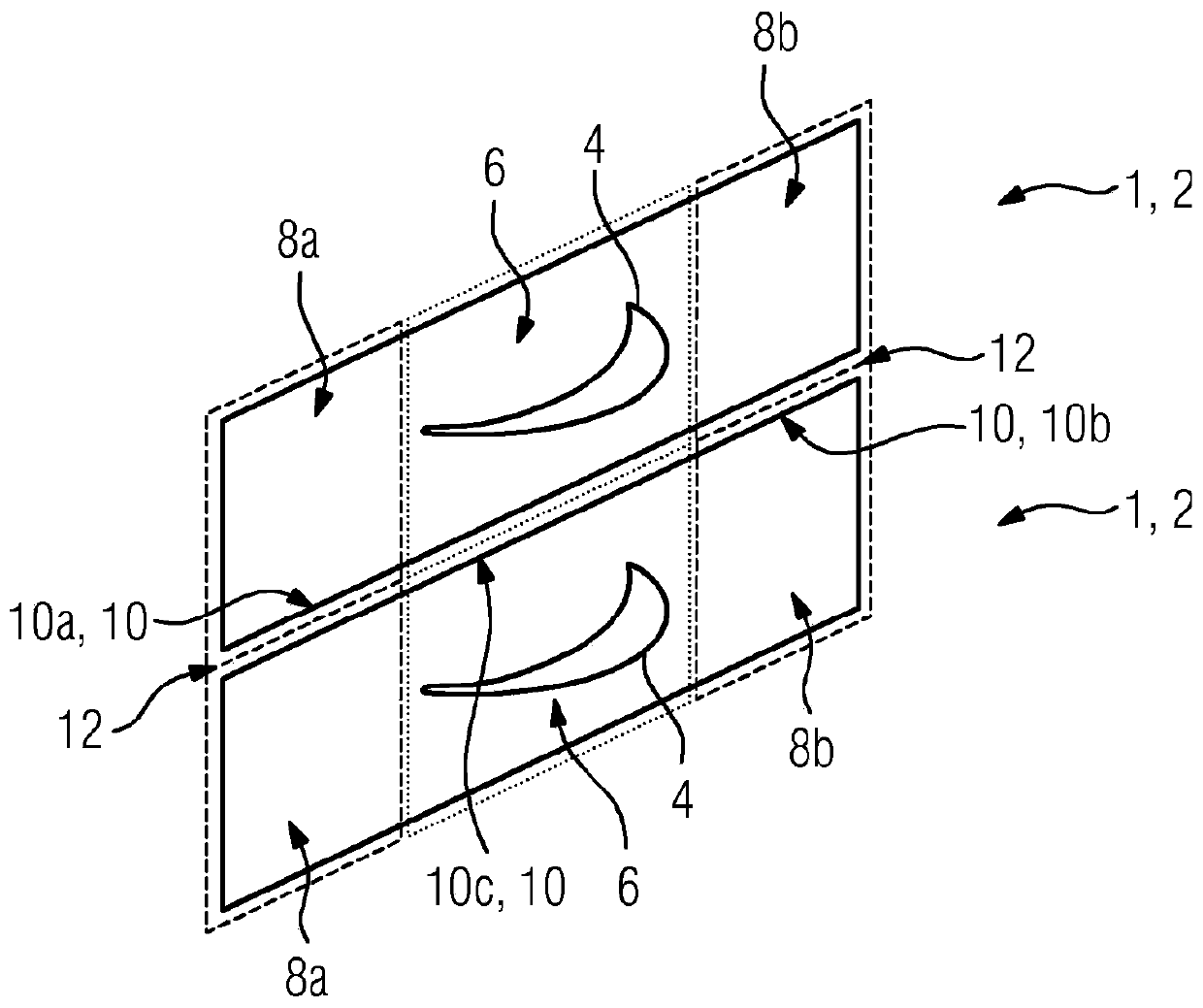

Method for coating turbine blades

ActiveCN107002214BReduced risk of partial separationReduce adhesionHot-dipping/immersion processesMolten spray coatingTurbine bladeEngineering

The invention proposes a method (2) for coating a turbine blade (1) comprising an airfoil (4) and at least one platform arranged at the end of the airfoil (4) (2), wherein the or each platform (2) has a contact region (6) and at least one planar raised region (8a, 8b) adjacent to the contact region (6), and the airfoil ( 4) terminating in the contact zone (6), with the following method steps: applying at least a first layer (22) of the coating (24) on the airfoil side on the platform (2), and applying the coating (24) ) of the at least first layer (22) remaining on the end face (10c) within the range of the contact zone (6), the at least first layer (22) of the coating (24) in the protruding zone (8a, 8b) are removed from at least one end face (10a, 10b) of the platform (2).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Filler for resinous composition, filler-containing slurry composition and filler-containing resinous composition as well as production process for filler for resinous composition

ActiveUS11091647B2Reduce contentLarge thermal expansion efficientInksFaujasite aluminosilicate zeoliteSilenesSlurry

Owner:ADMATECHS CO LTD

Valve with a pilot valve seat arranged in a diaphragm

ActiveUS10767786B2Large thermal expansionOperating means/releasing devices for valvesClassical mechanicsStructural engineering

The invention relates to a valve (1) comprising a main valve (2), a pilot valve (3), a housing (4), an inlet (5) and an outlet (8). Opening and closing of the main valve (2) is controlled by the pilot valve (3). A pilot valve seat (10) is arranged in a diaphragm (6). A pilot chamber (11) is arranged in the housing (4) separated from the inlet (5) and the outlet (8) by the diaphragm (6). Task of the invention is to provide a valve with a lower cost. According to the invention a support member (17) supports the diaphragm (6), wherein the support member (17) is guided in the housing, and wherein a radial gap (26) is arranged between the radially outer end of the diaphragm (6) and the housing (4) in a radial direction perpendicular to the opening direction of the pilot valve (3). Thereby, a cheaper, less resistant material for the diaphragm can be used.

Owner:DANFOSS AS

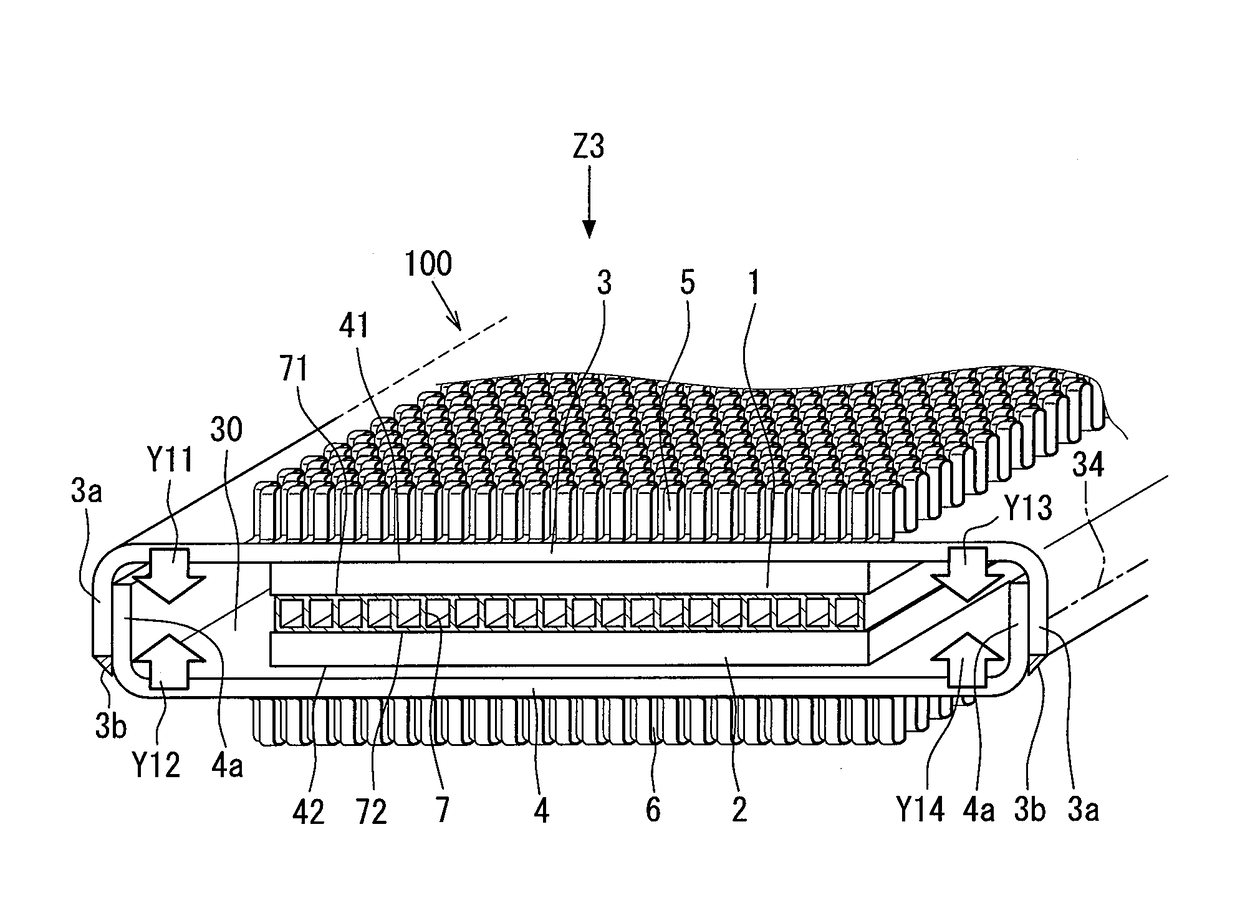

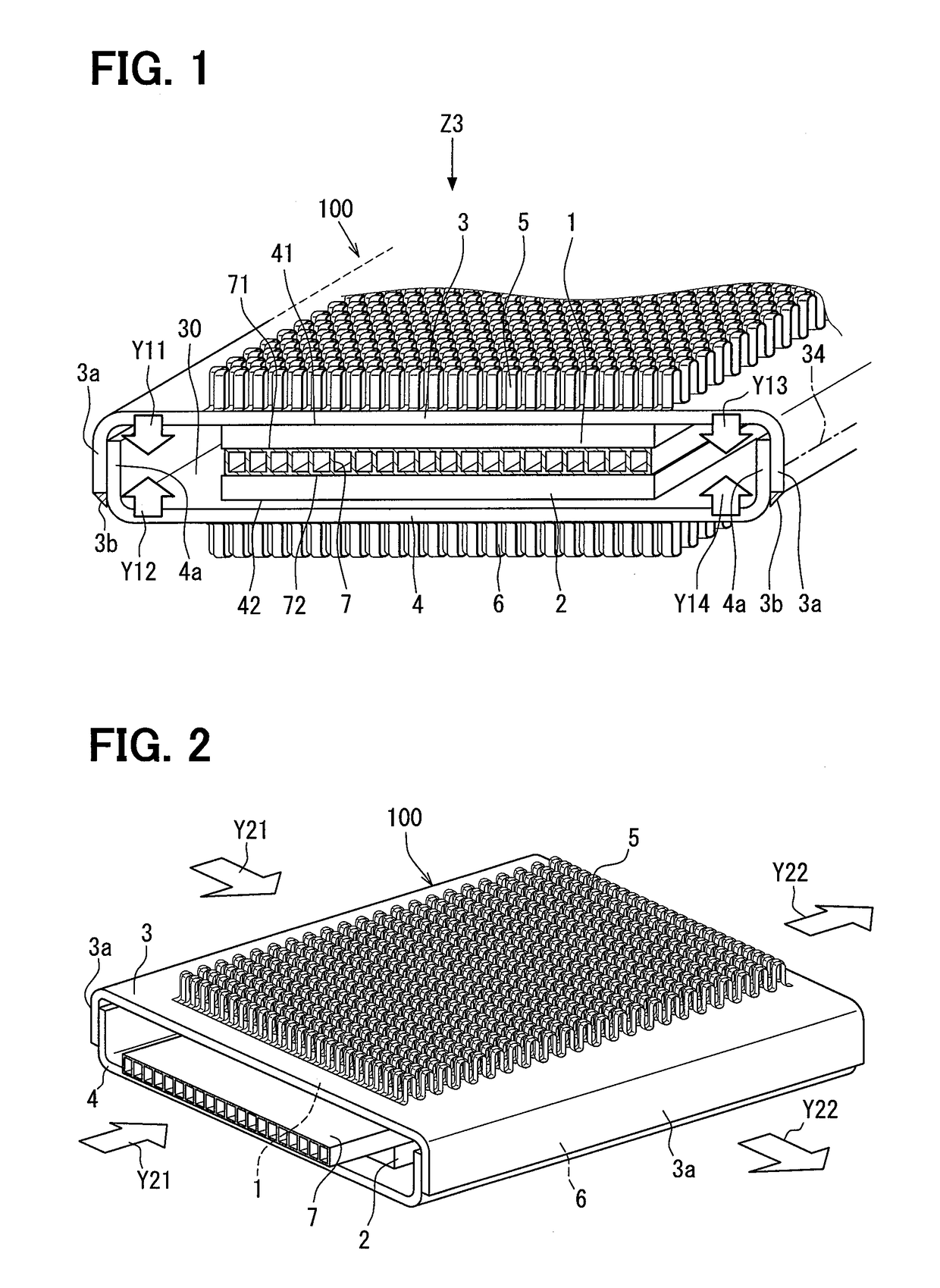

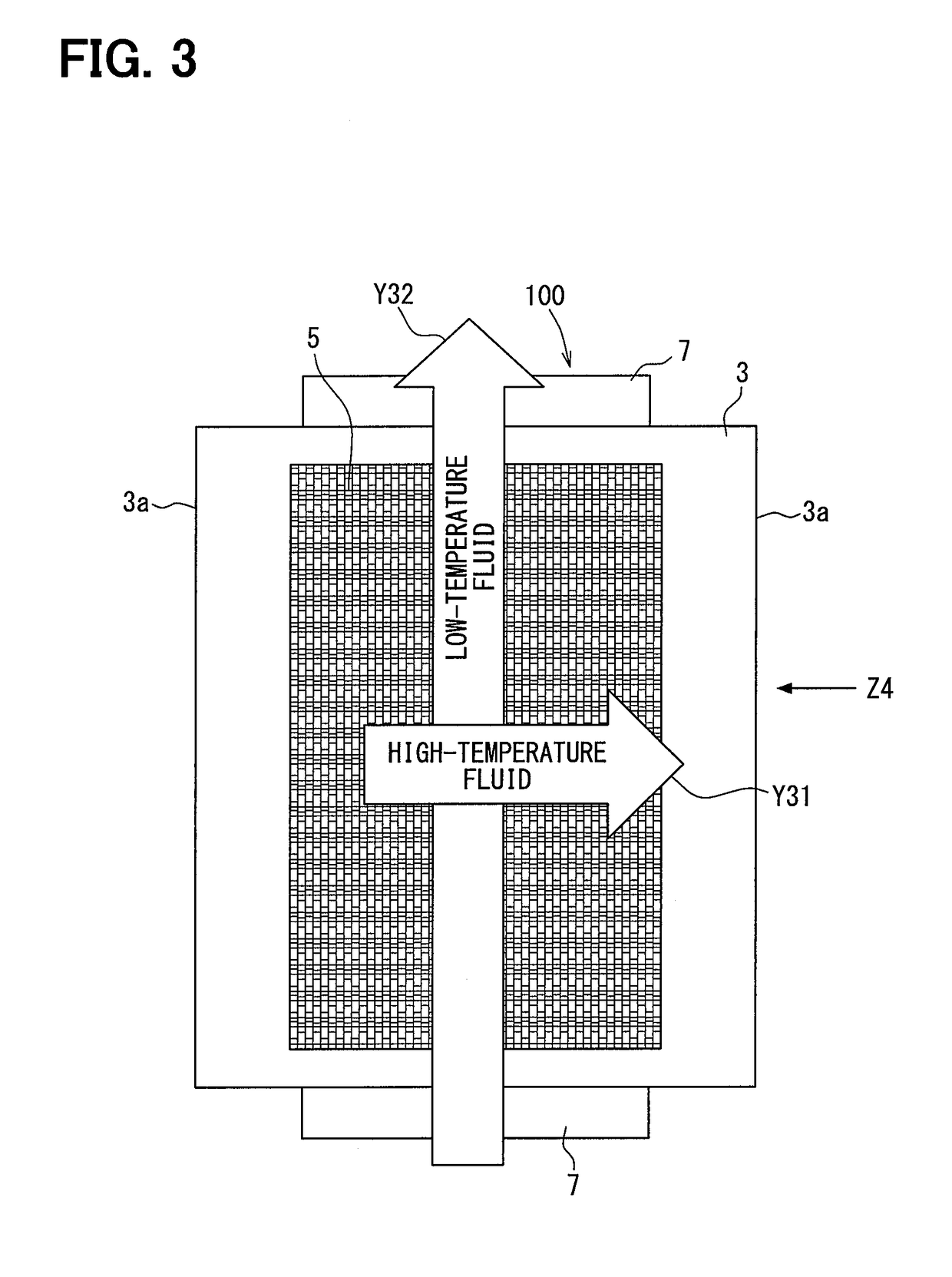

Thermoelectric power generation device

ActiveUS20180287035A1Reduce power generationReduce power generation efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectThermal expansionEngineering

A second fluid having a higher temperature than a first fluid, which flows in a duct, flows in contact with outside fins. Opposed regions of each power generation module and the duct apply pressure to and in contact with each other. Opposed regions of each power generation module and a corresponding one of a first outside plate and a second outside plate apply pressure to and in contact with each other. The duct is formed from a material having a thermal expansion coefficient larger than the first outside plate and the second outside plate. Additionally, two power generation modules are not necessarily required, and at least one power generation module is provided.

Owner:DENSO CORP

A kind of anti-cracking self-healing concrete and preparation method thereof

The invention discloses a crack-resistant self-repairing concrete and a preparation method thereof. The crack-resistant self-repairing concrete comprises 200-300 parts of cement, 100-180 parts of fly ash, 500-700 parts of gravel, 80-140 parts of water, 40 ‑60 parts of hemihydrate gypsum, 50‑100 parts of silicon powder, 20‑40 parts of polypropylene fiber, 10‑15 parts of silane coupling agent, 60‑80 parts of calcium oxide, 5‑10 parts of water reducer, 30‑50 parts Ammonium chloride, 10-20 parts of barium hydroxide octahydrate; its preparation method is mixing concrete slurry, mixing cement, fly ash, crushed stone, hemihydrate gypsum and silica fume, stirring for 30-40min, adding Water reducer and water, after stirring for 5-10min, add ammonium chloride and barium hydroxide octahydrate, stir for 40-60min, then add polypropylene fiber and silane coupling agent and stir for 20-30min to obtain concrete slurry; The calcium is sealed in the glass fiber tube, and then the glass fiber tube filled with calcium oxide is mixed in the concrete slurry to obtain the anti-crack self-repairing concrete. The invention has the advantages that the prepared concrete is anti-cracking, self-repairing cracks and has high strength after repairing.

Owner:北京天地建设砼制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com