Preparation method of high-strength waterproof rock wool board

A rock wool board, high-strength technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of high water absorption, shedding, poor cohesion of rock wool boards, etc., to improve waterproof performance, prevent The effect of cracking and shedding and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

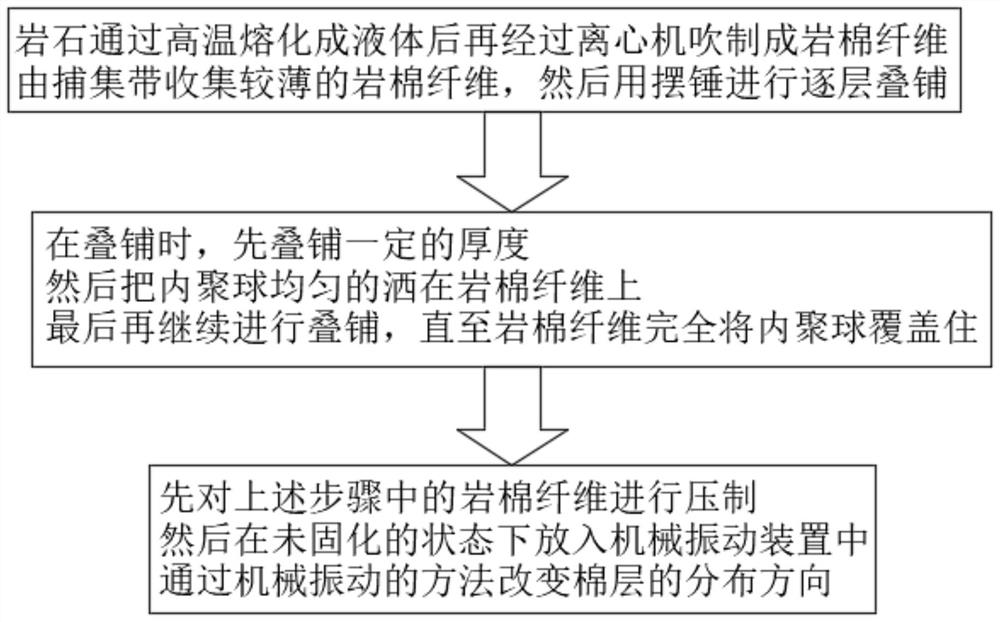

[0046] see Figure 1-7 , a preparation method of high-strength waterproof rock wool board, please refer to figure 1 , including the following steps:

[0047] S1, the rock is melted into a liquid at high temperature and then blown into rock wool fibers by a centrifuge. The thinner rock wool fibers are collected by the trapping belt, and then layer by layer with a pendulum;

[0048] S2. When stacking, first stack a certain thickness, then sprinkle the cohesive balls evenly on the rock wool fibers, and finally continue to stack until the rock wool fibers completely cover the cohesive balls;

[0049] S3, first compress the rock wool fibers in the above steps, and then put them into a mechanical vibration device in an uncured state, and change the distribution direction of the cotton layer by mechanical vibration.

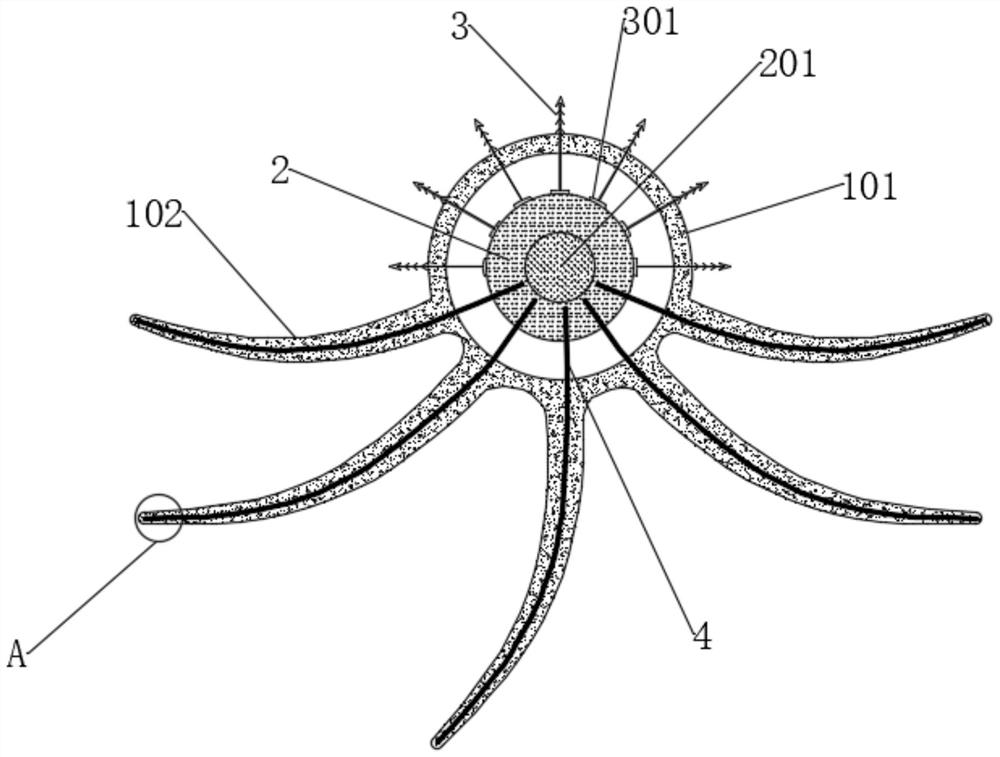

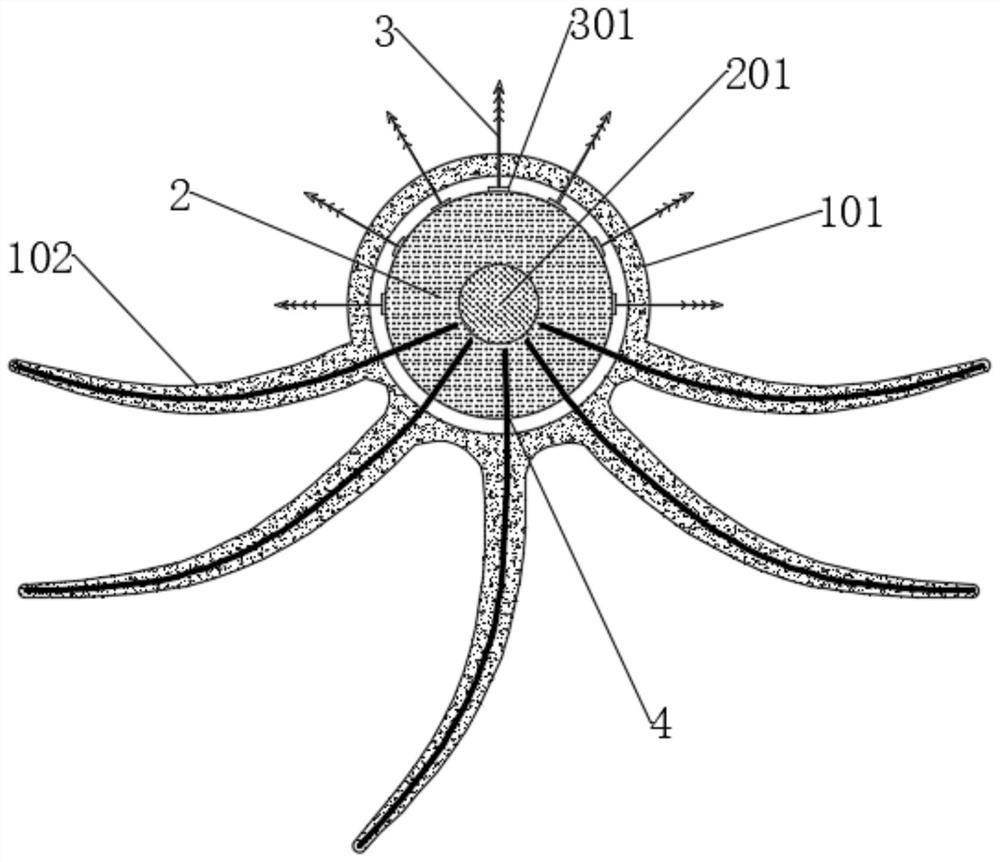

[0050] see Figure 6-7 , the cohesive ball in step S2 includes a mother body 101 and a plurality of tentacles 102, and the plurality of tentacles 102 are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com