Method for coating turbine blades

A technology for turbine blades and coatings, applied in the directions of blade support elements, coatings, metal material coating processes, etc., can solve the problems of TBC shedding, adhesion deterioration, etc., and achieve the effect of reducing the risk of local separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

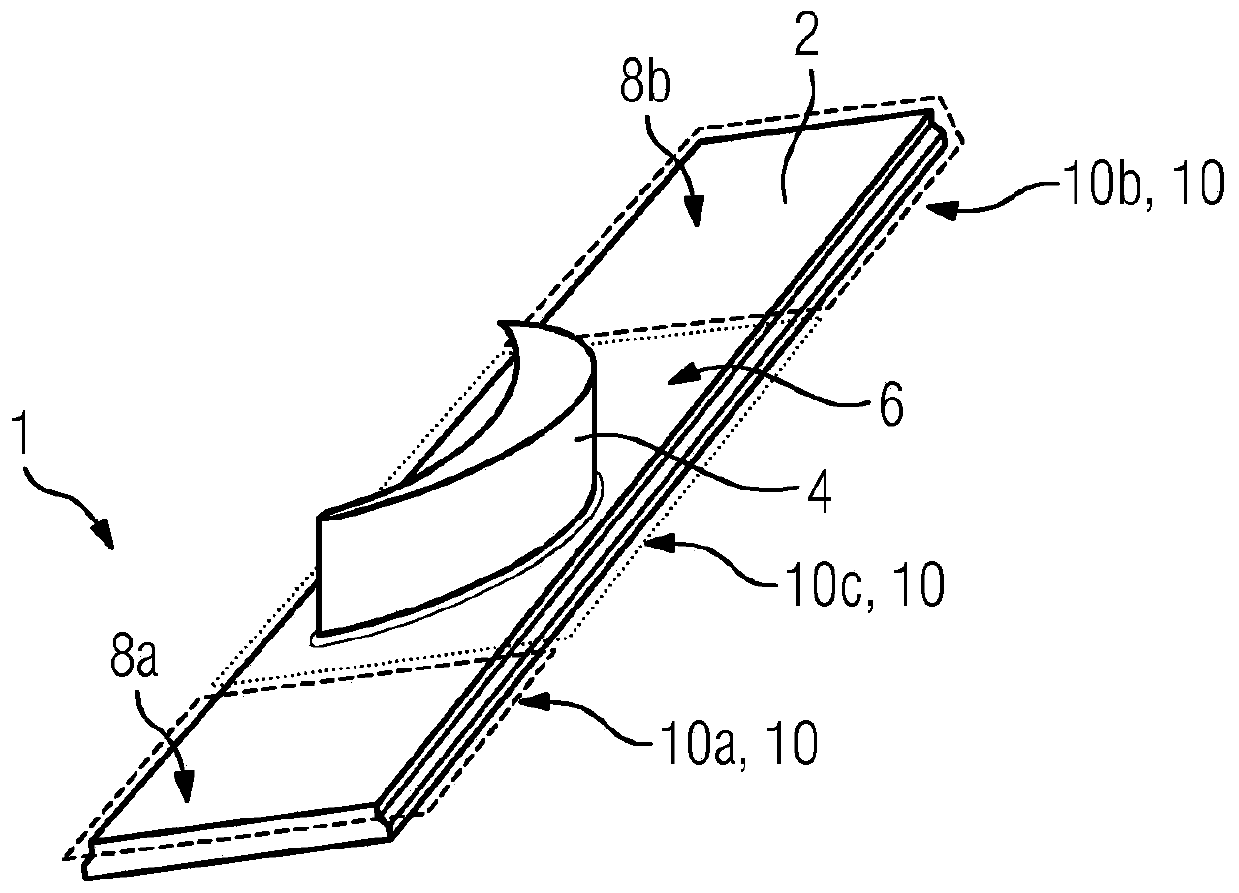

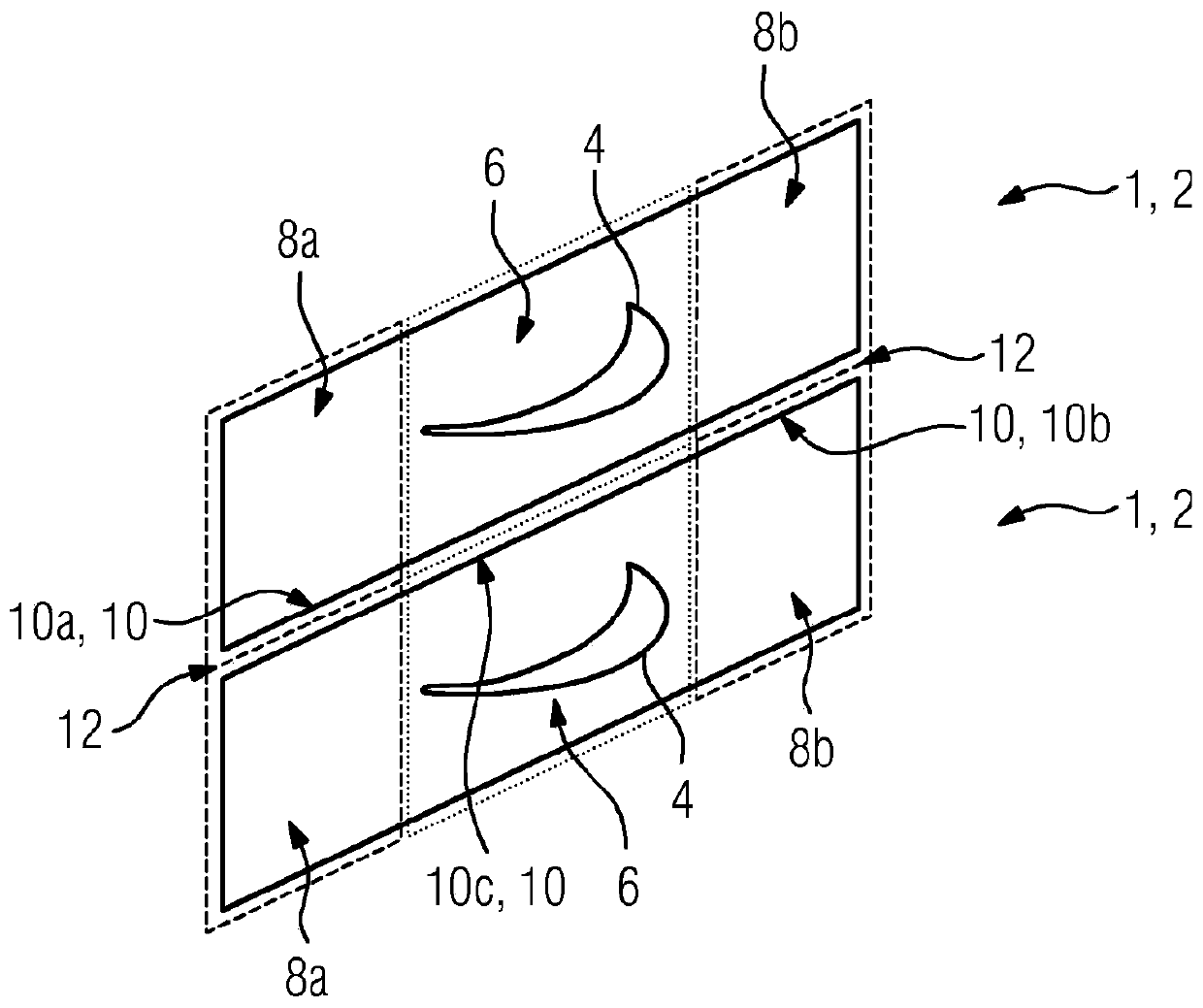

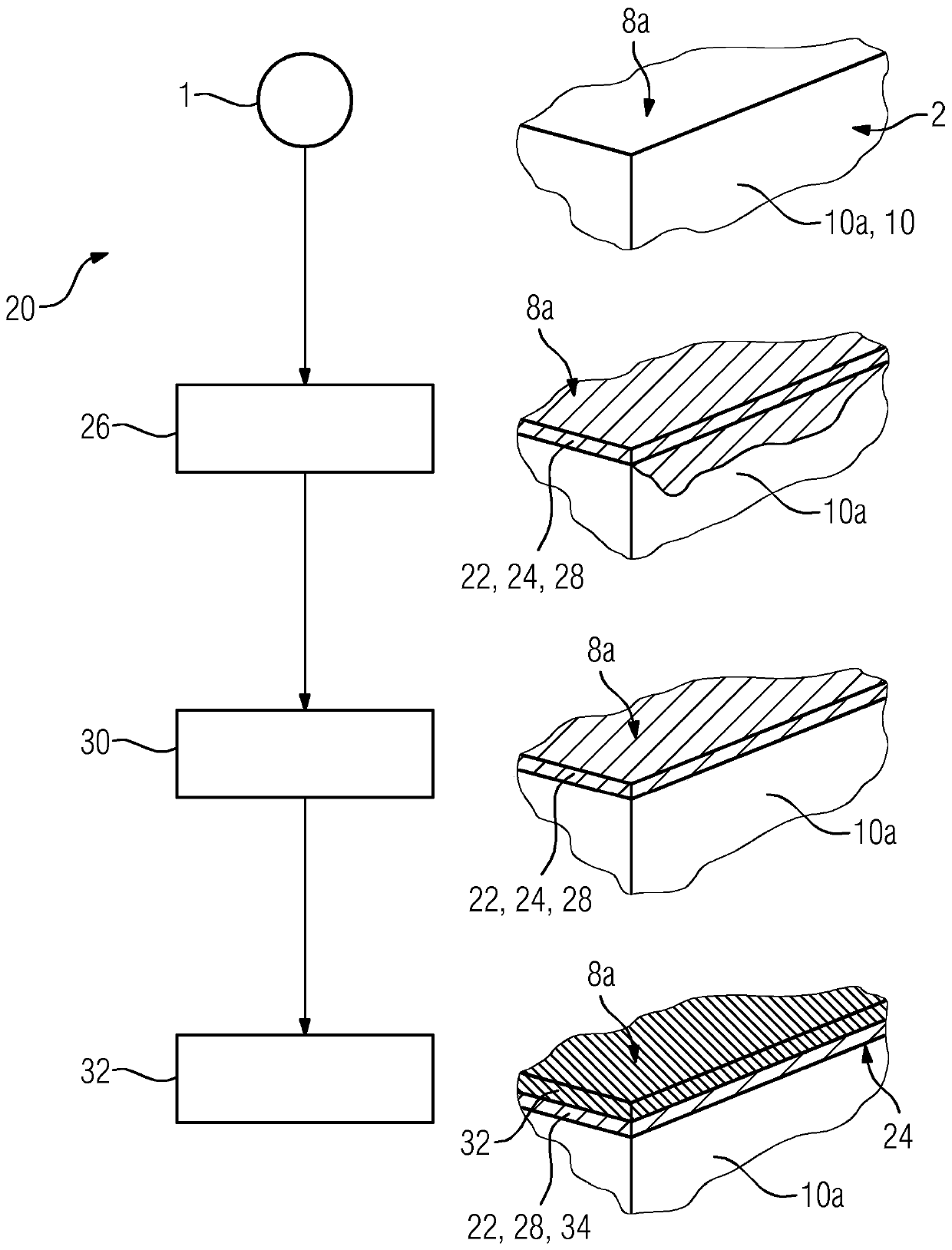

[0035] figure 1 An oblique view of the end of a turbine blade 1 is schematically shown in . Therein, the turbine blade 1 has a platform 2 and an airfoil 4 , wherein the airfoil 4 is implicitly indicated as the airfoil tip in the schematic illustration. The region of the platform 2 that is in contact with the airfoil 4 or transitions into the airfoil 4 is defined here as a contact region 6 . This is indicated by a dotted border. At the contact area 6, on the platform 2, in both directions, the airfoil 4 adjoins a convex protruding area 8a, 8b, respectively. These raised areas 8 a , 8 b are each marked here by a dashed border. If the first layer of the coating is now applied by spraying on the turbine blade 1 , it is generally unavoidable when spraying the platform 2 on the airfoil side that also wets the end face 10 of the platform 2 with a portion of the coating. In the region of the raised areas 8a, 8b, the remnants of the first layer of the coating are removed from the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com