Water dispenser

A water dispenser and water bucket technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of high power consumption of hot water machines, high starting frequency of thermal resistance, and more space for water dispensers, so as to avoid low liquid level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

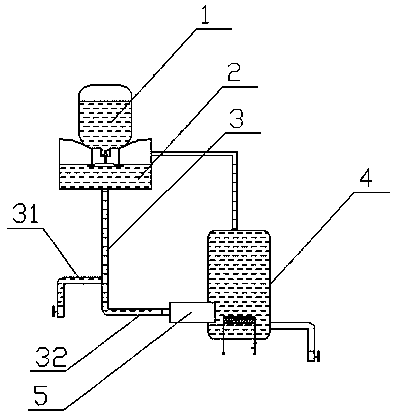

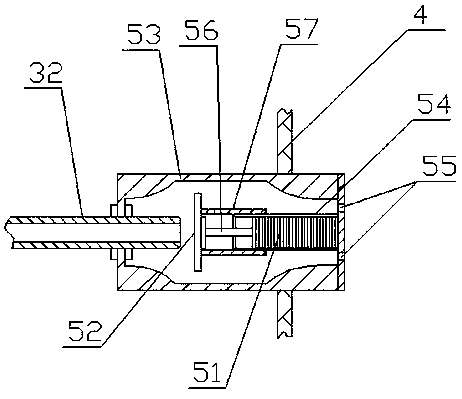

[0020] like figure 1 , image 3 The shown water dispenser includes a bucket 1, a cold water tank 2, an outlet pipe 3 and a hot water tank 4. The upper end of the cold water tank 2 is provided with a smart seat with a built-in smart head, and the bucket is connected to the cold water tank via the smart seat; the cold water tank The lower part of the outlet pipe is connected to the upper end of the outlet pipe; the lower branch of the outlet pipe 3 forms two branches, namely the first branch 31 and the second branch 32, and the first branch is connected to the water outlet valve to form a cold water outlet; the second branch The side wall of the hot water tank is connected with a hot water outlet pipe; the second branch road is connected to the hot water tank via the anti-hot water return unit 5, and the anti-hot water return unit 5 Built-in h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com