Closed-extrusion and molding method of flange

A technology of occlusion extrusion and extrusion forming, which is applied in the field of metal pressure processing, can solve the problems of low utilization rate of parts material, many subsequent processing procedures, and high manufacturing cost, and achieves low manufacturing cost, compact production process, and reduced processing. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

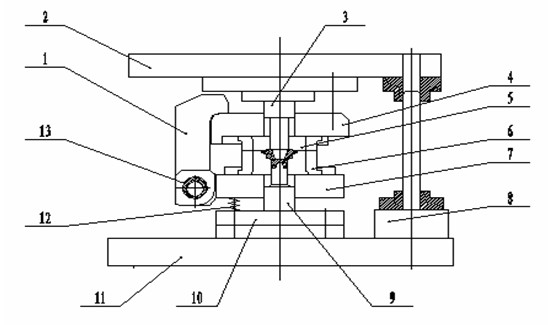

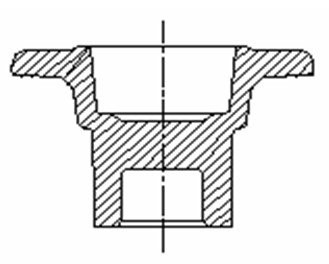

[0016] The concrete steps of a kind of occlusive extrusion forming method of flange are as follows:

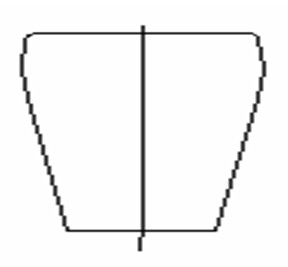

[0017] (1) Prepare the flange blank: the raw material is cut into the flange blank, and the diameter of the blank is calculated according to the diameter of the flange journal, D b =D p +C, where D p , journal diameter, blank diameter D b, C=0-6mm, the size of the axial height h of the blank is determined by the condition that the volume of the blank is equal to the volume of the flange forging.

[0018] (2) Upsetting at the end: Inductively heat the flange blank, and perform local upsetting at the end to obtain the upset flange blank, and provide a preform for radial extrusion.

[0019] (3) Occlusion radial extrusion forming process:

[0020] When the mold is opened, the flange upsetting piece is placed into the cavity of the floating die 5, the upper mold base 2 moves downward, and the upper and lower floating dies are pressed together under the action of the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com