Method for weakening hydration repulsive force among coal slime particles to promote agglomeration by alternating electric field

An alternating electric field and slime water technology, applied in the direction of magnetic field/electric field water/sewage treatment, can solve the problems of large equipment, large settlement area, and large production lag, so as to reduce the area of settlement equipment, reduce environmental pollution, The effect of compact production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The specific implementation of the method of alternating electric field weakening the hydration repulsion between coal slime particles to promote agglomeration is to apply an alternating electric field to the coal slime water, thereby weakening the hydration repulsion between coal slime particles to promote the reunion of coal slime particles; coal slime water refers to coal slime Coal slime water with a hydration film thickness of not less than 10nm on the particle surface.

[0024] Determination of thickness of hydration film on the surface of coal slime particles:

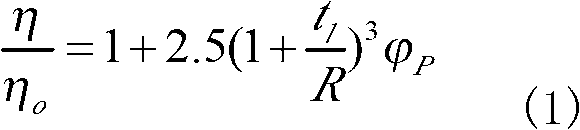

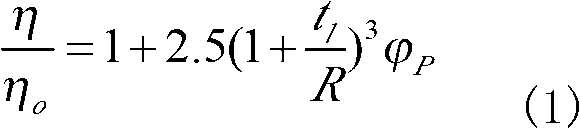

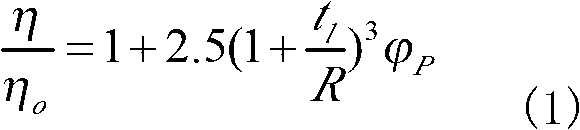

[0025] Set the slime particles as spheres, and use formula (1) to obtain the thickness of the hydration film:

[0026]

[0027] In formula (1), η is the viscosity of coal slime water; η o is the viscosity of the water medium after removing the slime particles; t l is the thickness of the hydration film; R is the radius of the dry slime particle; Among them, V is the total volume of the slime soluti...

Embodiment 1

[0033] The concentration of the slime water is 10g / L, the pH value is 8, the main minerals in the slime are quartz and kaolin, the particle size is less than 0.10mm, and no chemical agent is added. An alternating electric field is applied to the slime water. The voltage of the alternating electric field is 300V, the frequency The frequency is 100Hz, and the waveform is a sine wave, so that the slime water is settled, and the light transmittance of the supernatant is 7.5% higher than that of natural settlement.

Embodiment 2

[0035] The concentration of the slime water is 30g / L, the pH value is 8.5, the main minerals in the slime are quartz and kaolin, the particle size is less than 0.074mm, and no chemicals are added. An alternating electric field is applied to the slime water. The voltage of the alternating electric field is 300V, the frequency It is 100Hz, and the waveform is sine wave, so that the slime water is settled, and the light transmittance of the supernatant is 6.8% higher than that of natural settlement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com