Functional nanocellulose-boron nitride composite film and preparation method thereof

A nanocellulose, composite film technology, applied in the direction of coating, can solve the problems of non-hydrophobicity, complex preparation process, and many layers of composite film, achieve high hydrophobic insulation performance, expand the scope of application, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The functional nanocellulose-boron nitride composite film provided in this embodiment is composed of a nanocellulose-boron nitride dispersion liquid, which forms a deposition layer after suction filtration on a mixed cellulose ester microporous filter membrane. The inner layer of the composite film made by hot pressing and drying; and the inner layer of the composite film is a nanocellulose-boron nitride composite single-layer structure, wherein the content of boron nitride is 1%-7wt% (accounting for the dry matter of the film content).

[0031] Wherein, the diameter of the mixed cellulose ester filter membrane is 44mm and the pore diameter is 0.45um.

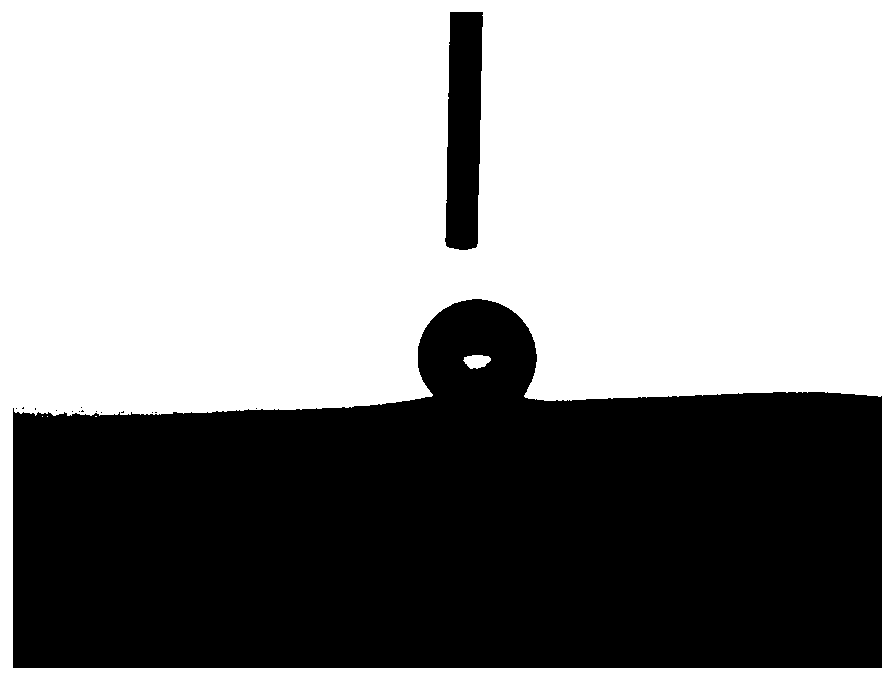

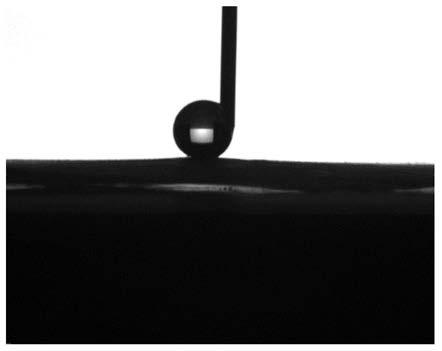

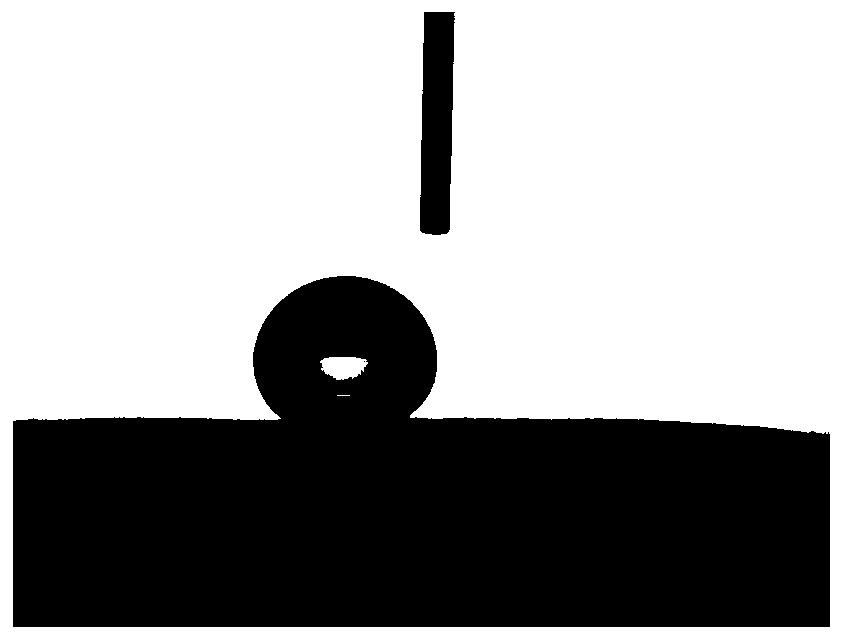

[0032] In the functional nanocellulose-boron nitride composite film, the upper and lower surfaces of the inner layer of the composite film are respectively provided with a hydrophobic outer layer formed by a modified organic silicon material, and the outer layer completely covers the inner layer of the composite film. C...

Embodiment 2

[0042] Embodiment 2: The functional nanocellulose-boron nitride composite film provided in this embodiment and its preparation method are basically the same as in Embodiment 1, except that:

[0043] (1) Add 0.0021g of boron nitride and 0.0679g of nanocellulose into the dispersant, respectively prepare boron nitride dispersion with a concentration of 2.2mg / mL, and nanocellulose dispersion with a concentration of 1.5mg / mL. liquid, then the above-mentioned nanocellulose dispersion and boron nitride dispersion were mixed, stirred for 30 minutes, and continued ultrasonication in a cell pulverizer (80W) for 15 minutes to disperse evenly to obtain a nanocellulose-boron nitride dispersion. The dispersant is deionized water.

[0044] (2) Place the nanocellulose-boron nitride dispersion liquid obtained in the above step (1) on the film (mixed cellulose ester microporous filter membrane, diameter 44nm, aperture 0.45um) and carry out suction filtration to form a deposition layer, The res...

Embodiment 3

[0048] The functional nanocellulose-boron nitride composite film provided in this example and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0049] (1) Add 0.0035g of boron nitride and 0.0665g of nanocellulose into the dispersant, respectively prepare a boron nitride dispersion with a concentration of 2.2mg / mL, and a dispersion of nanocellulose with a concentration of 1.5mg / mL. liquid, then the above-mentioned nanocellulose dispersion and boron nitride dispersion were mixed, stirred for 30 minutes, and continued ultrasonication in a cell pulverizer (80W) for 15 minutes to disperse evenly to obtain a nanocellulose-boron nitride dispersion. The dispersant is deionized water;

[0050] (2) Place the nanocellulose-boron nitride dispersion liquid obtained in the above step (1) on the film (mixed cellulose ester microporous filter membrane, diameter 44mm, aperture 0.45um) to obtain the deposition layer by suction filtration, and The deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com