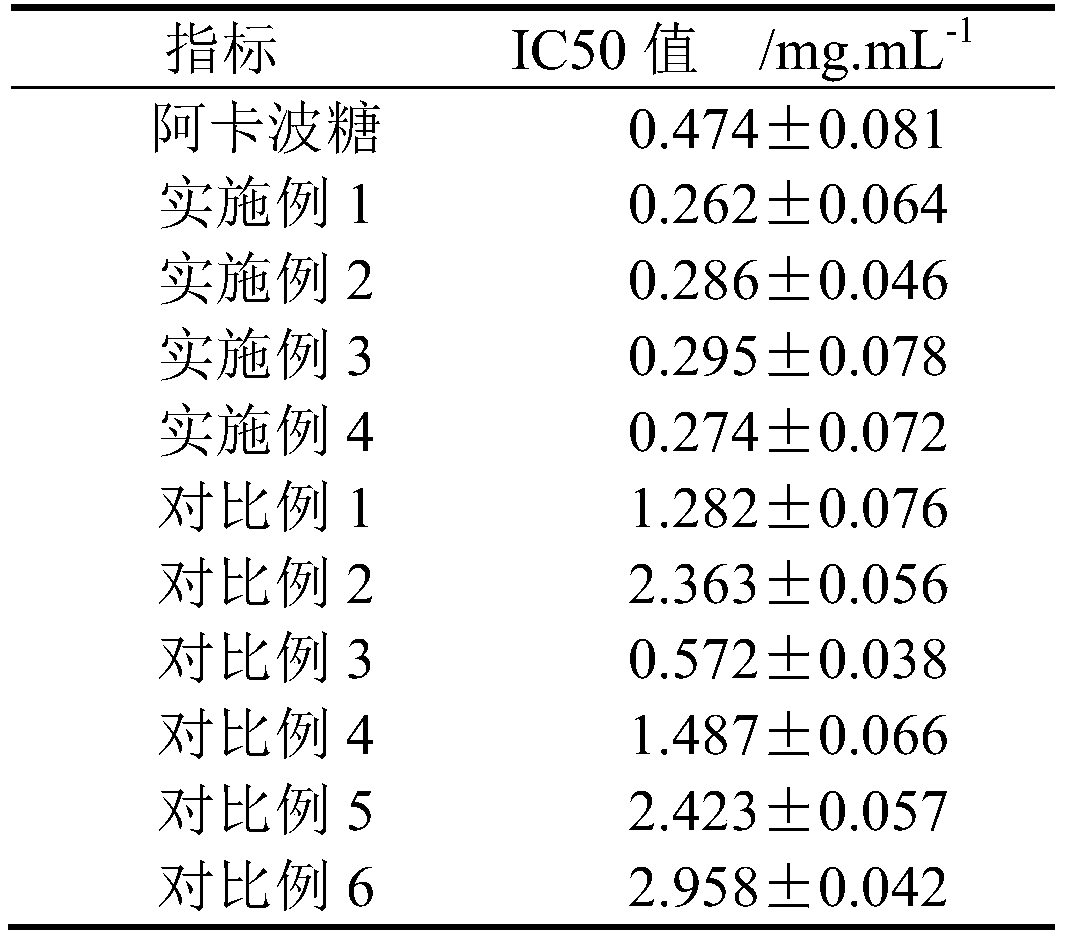

Soybean peptide with alpha-glucosidase activity inhibition function, preparation method and application

A technology of glucosidase and soybean peptide, applied in the field of soybean peptide and preparation, can solve the problems of incapable of industrial scale preparation, complicated separation and purification process, low product activity, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Dispersion and dissolution of soybean protein isolate powder: use deionized water equivalent to 9 times the quality of soybean protein isolate powder (model SD-300, Linyi Shansong Biological Products Co., Ltd., the same below) to prepare soybean protein isolate powder For protein slurry, disperse and mix the slurry at a shear rate of 2000rpm for 20min, and raise the temperature to 55°C;

[0049] (2) Alkaline protease enzymolysis: the pH value of the protein slurry dispersed and mixed in step (1) is adjusted to 8.0 with a NaOH solution with a concentration of 2mol / L, and an alkaline solution equivalent to 1.5% of the quality of soybean protein isolate powder is added. Protease Alcalase 2.4L, keep stirring at a constant temperature of 55°C (at a speed of 36rpm) for enzymolysis for 6h;

[0050] (3) Adjust the pH of the enzymolysis solution, inactivate the enzyme, and centrifuge: adjust the pH value of the enzymolysis solution in step (2) to 4.5 with a concentration of ...

Embodiment 2

[0056] (1) Dispersion and dissolution of soybean protein isolate powder: use deionized water equivalent to 12 times the quality of soybean protein isolate powder to prepare protein slurry from soybean protein isolate powder, disperse and mix the slurry for 10 minutes at a shear rate of 3000 rpm, and heat up to 50°C;

[0057] (2) Alkaline protease hydrolysis: adjust the pH value of the protein slurry dispersed and mixed in step (1) to 9.0 with a concentration of 4mol / L NaOH solution, and add alkaline protease equivalent to 0.5% of the quality of soybean protein isolate powder Alcalase 2.4L, keep stirring at a constant temperature of 50°C (36rpm) for enzymolysis for 10h;

[0058] (3) Adjust the pH of the enzymolysis solution, inactivate the enzyme, and centrifuge: adjust the pH value of the enzymolysis solution in step (2) to 4.2 with a concentration of 4mol / L HCl solution, raise the temperature to 95°C for 10 minutes to inactivate the enzyme, and pump it into the horizontal Th...

Embodiment 3

[0064] (1) Dispersion and dissolution of soybean protein isolate powder: use deionized water equivalent to 6 times the quality of soybean protein isolate powder to prepare protein slurry from soybean protein isolate powder, disperse and mix the slurry for 15 minutes at a shear rate of 2500 rpm, and heat up to 50°C;

[0065] (2) Alkaline protease enzymatic hydrolysis: adjust the pH value of the protein slurry dispersed and mixed in step (1) to 7.0 with a concentration of 1mol / L NaOH solution, and add alkaline protease equivalent to 3.0% of the mass of soybean protein isolate Alcalase 2.4L, keep stirring at a constant temperature of 60°C (at a speed of 36rpm) for 2 hours;

[0066] (3) Adjust the pH of the enzymolysis solution, inactivate the enzyme, and centrifuge: adjust the pH value of the enzymolysis solution in step (2) to 4.8 with a concentration of 2mol / L HCl solution, raise the temperature to 85°C for 30min to inactivate the enzyme, and pump it into the horizontal The sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com