Flat plate solar collector framing and backplate lamination automatic assembling method and system thereof

A flat-plate collector and automatic assembly technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the production and processing costs of flat-plate collectors, restricting the production efficiency of flat-plate collectors, and consuming manpower and material resources , to achieve the effect of compact structure, high production efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

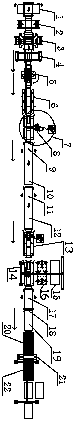

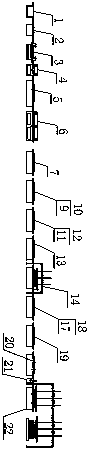

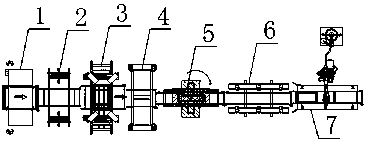

[0025] see Figure 1-6 , an automatic assembly system for flat plate heat collector group frame back plate pressing, including power logistics line, pre-installation table 1, normalization table 2, automatic frame assembly machine 3, short side back plate pressing table 4, ninety degree Rotary station 5, long-side backboard pressing 6, robot automatic gluing system 7, six-axis robot 8, workbench for installing thermal insulation cotton 9, workbench for installing board core 10, workbench for assembling rubber ring 11, cleaning and inspection work Table 12, automatic gluing machine 13, glass installation system, installation of glass bead workbench 17, bead press device 18, inspection and labeling workbench 19, automatic packaging system and automatic palletizer 22; glass installation system includes glass Manipulator 14 and positioning platform 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com