Ultrafiltration/nanofiltration double-membrane high-efficiency pumpkin oligosaccharide purifying method

A technology of oligosaccharides and ultrafiltration membranes, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems that pumpkin oligosaccharides have not been reported, and achieve compact production process, high-efficiency removal, and mild treatment conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

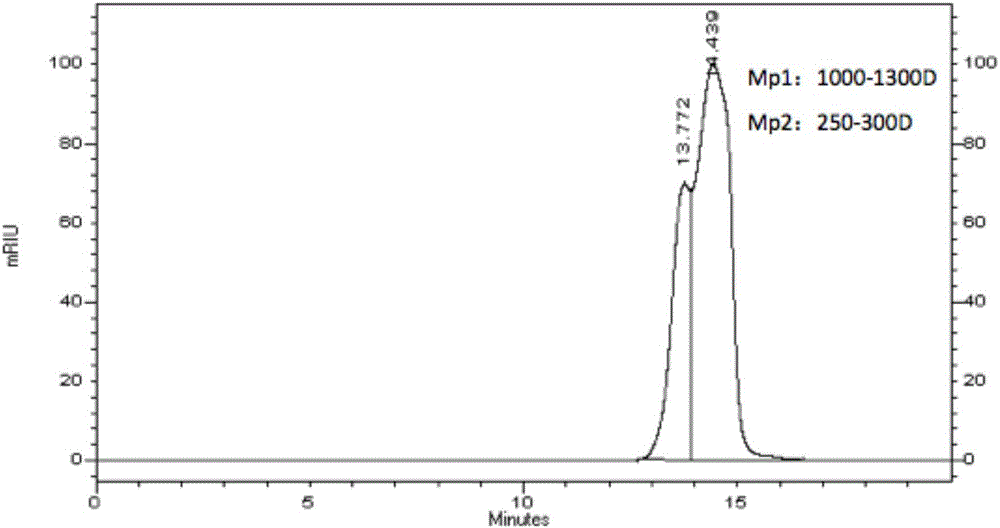

Image

Examples

Embodiment 1

[0022] A method for ultrafiltration / nanofiltration double-membrane efficient purification of pumpkin oligosaccharides is carried out according to the following steps:

[0023] (1) Remove the seeds of the pumpkin and cut into pieces, add 3 times the weight of water to make a slurry, use pectinase to enzymatically hydrolyze, take the supernatant by centrifugation, concentrate to 1 / 3 of the original supernatant volume, add 3 times the volume of 80% ethanol Precipitate, centrifuge and take the supernatant to obtain the pumpkin oligosaccharide crude extract;

[0024] (2) Pass the pumpkin oligosaccharide crude extract through a 20 μm filter bag and dilute to a conductivity of 4411ppm, and the temperature of the feed liquid is 21°C;

[0025] (3) Perform ultrafiltration, the working frequency of the ultrafiltration section is 26.7Hz, the inlet pressure is 0.6MPa, and the permeate flow rate is 16L / h;

[0026] (4) When the stock solution of the feed liquid is concentrated to 1 / 3 of the...

Embodiment 2

[0032] A method for ultrafiltration / nanofiltration double-membrane efficient purification of pumpkin oligosaccharides is carried out according to the following steps:

[0033] (1) Remove the seeds of the pumpkin and cut into pieces, add 2 times the weight of water to make a slurry, use amylase to enzymatically hydrolyze, take the supernatant by centrifugation, concentrate to 1 / 2 of the original supernatant volume, add 2 times the volume of 80% ethanol to precipitate , and centrifuge to take the supernatant to obtain the pumpkin oligosaccharide crude extract;

[0034] (2) Pass the pumpkin oligosaccharide crude extract through a 20 μm filter bag and dilute to a conductivity of 4233ppm, and the temperature of the feed liquid is 23°C;

[0035] (3) The working frequency of the ultrafiltration section is 27.1Hz, the inlet pressure is 0.6MPa, and the permeate flow rate is 16L / h;

[0036] (4) When the stock solution of the feed liquid is concentrated to 1 / 4 of the volume of the feed ...

Embodiment 3

[0042] A method for ultrafiltration / nanofiltration double-membrane efficient purification of pumpkin oligosaccharides is carried out according to the following steps:

[0043](1) Remove the seeds and cut the pumpkin into pieces, add 5 times the weight of water to make a slurry, enzymatically hydrolyze with pullulanase, centrifuge to get the supernatant, concentrate to 1 / 5 of the original supernatant volume, add 4 times the volume of 80 % ethanol precipitation, centrifugation to take the supernatant to obtain the pumpkin oligosaccharide crude extract

[0044] (2) Pass the pumpkin oligosaccharide crude extract through a 20 μm filter bag and dilute to a conductivity of 4052ppm, and the temperature of the feed liquid is 19°C;

[0045] (3) The working frequency of the ultrafiltration section is 27.6Hz, the inlet pressure is 0.7MPa, and the permeate flow rate is 18L / h;

[0046] (4) When the stock solution of the feed liquid is concentrated to 1 / 2 of the volume of the feed liquid af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com