Automatic release appliance for optical lens

An optical lens and release technology, applied in glass manufacturing equipment, glass forming, glass pressing, etc., can solve the problems of high mold damage rate, large floor space, waste of water, etc., and achieve less intermediate links and land occupation. Small area and the effect of reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

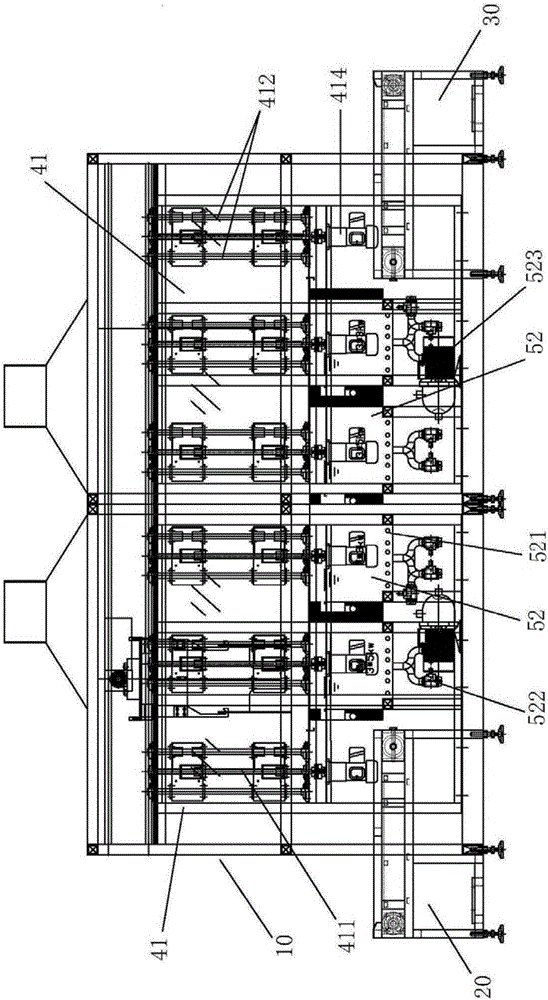

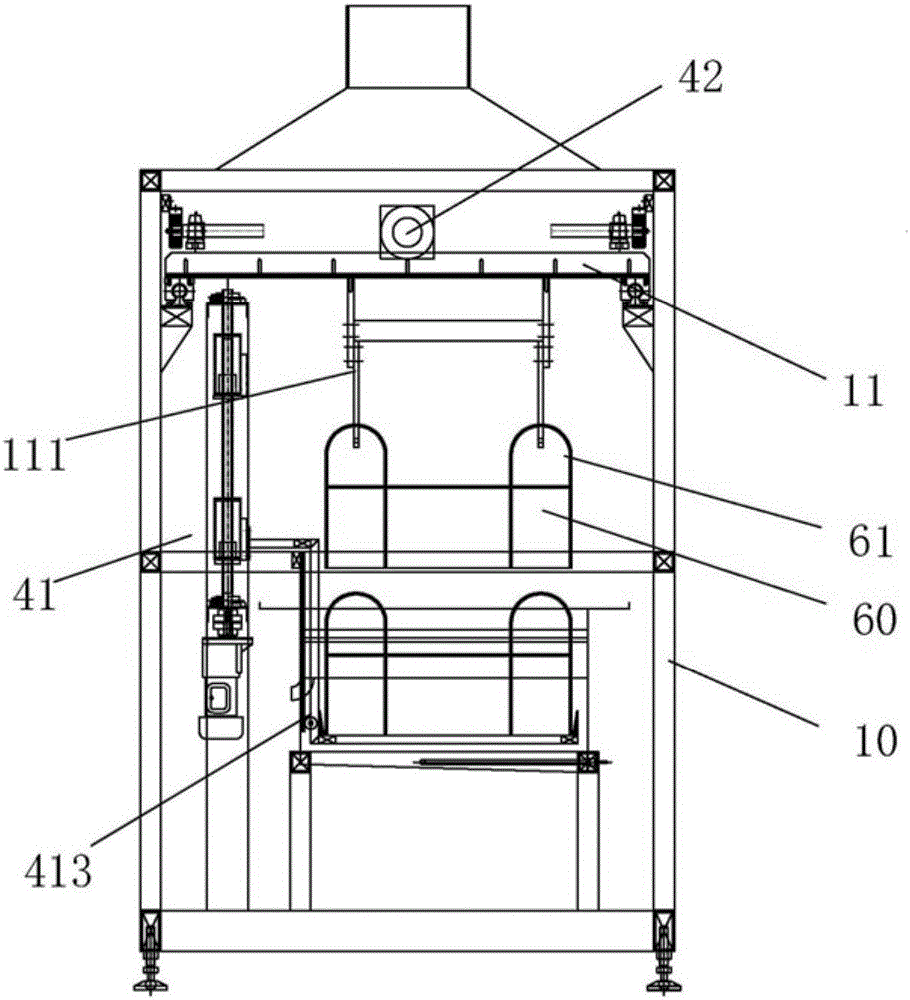

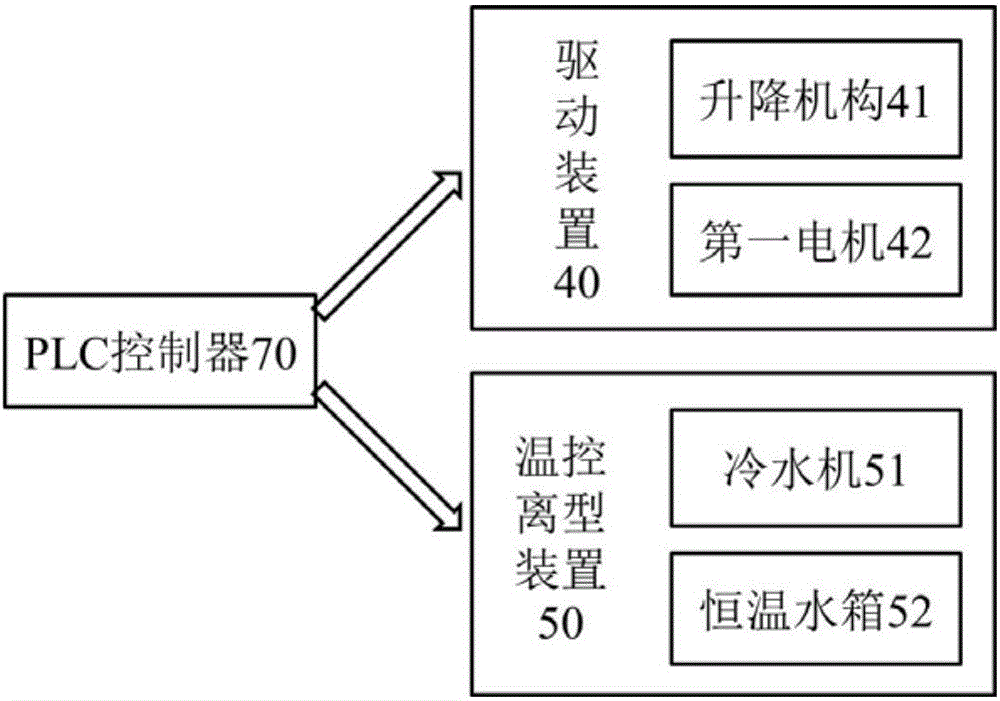

[0036] Such as Figure 1 to Figure 3 As shown, the optical lens automatic release equipment of the present invention includes a frame 10 , a loading table 20 , a feeding table 30 , a driving device 40 , a temperature-controlled release device 50 , a material column 60 and a PLC controller 70 .

[0037] The loading platform 20 and the unloading platform 30 are respectively arranged on both sides of the frame 10, the driving device 40 is installed inside the frame 10, and the constant temperature water tank 52 in the temperature control release device 50 (see description below) ) is arranged in the bottom space in the frame 10; the material column 60 is fixedly connected with the lifting mechanism 41 (described below) in the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com