Opening type drying tunnel using multi-connected type heat pump

A multi-joint, drying tunnel technology, applied in drying, dryer, lighting and heating equipment, etc., can solve problems such as insufficient heating heat, save plant space, reduce production costs, reduce heat loss and fan power. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

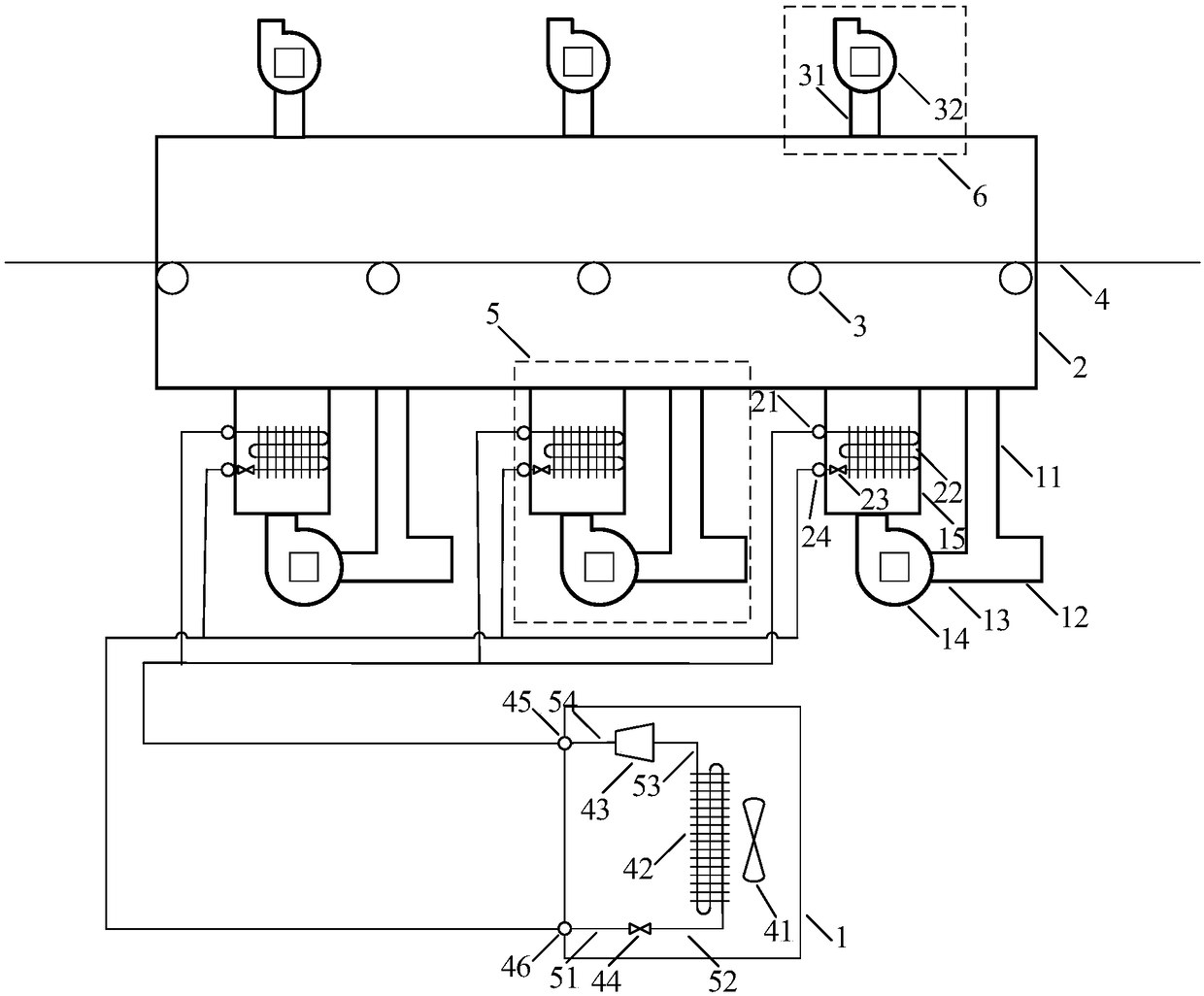

[0042] An open drying tunnel (air source heat pump) using a multi-connected heat pump, the structure and flow are as follows figure 1 As shown, it includes a drying tunnel 2, a heating assembly 5, an exhaust assembly 6, and a heat pump host 1. Three heating assemblies 5 are arranged along the length of the drying tunnel 2 to provide hot air to the drying tunnel 2. The exhaust assembly 6 is arranged along the drying tunnel. 2. Three are arranged in the length direction, which are used for exhausting the drying tunnel 2. One heat pump host 1 is arranged to connect with each heating assembly 5 and supply heat to each heating assembly 5 respectively.

[0043]Wherein, the heating assembly 5 includes a return air duct 11, a fresh air duct 12, an air supply duct 13, an air supply fan 14 and a heating box 15, and one end of the return air duct 11 is connected with the drying duct 2, and the other end is connected with the supply air duct. Road 13 is connected, one end of fresh air duc...

Embodiment 2

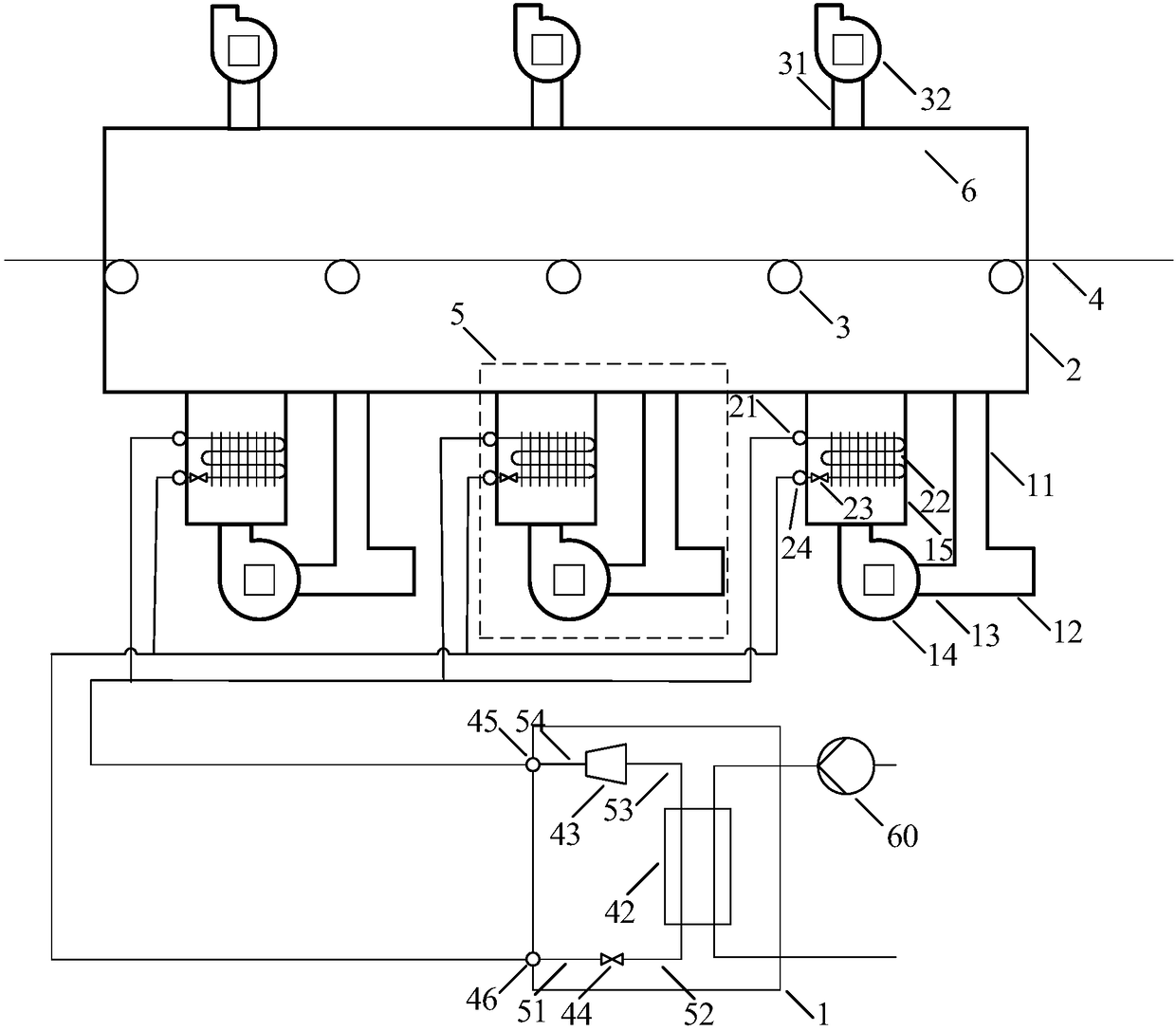

[0056] An open drying tunnel (water source heat pump) using a multi-connected heat pump, the structure and flow are as follows figure 2 shown. Compared with Embodiment 1, in this embodiment, the heat pump host 1 takes heat from water, the evaporator 42 is a refrigerant-water heat exchanger, the heat pump host is provided with a water pump 60, and the water pump 60 passes through the water channel of the water pipe and the evaporator 42 connect. Common types of refrigerant-water heat exchangers such as plate heat exchangers, casing heat exchangers, etc. The heat pump host is connected to the water pipe, and the heat pump cycle absorbs heat from water or solution, and the generated cold energy can be used as chilled water for equipment cooling or air conditioning cold source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com