A raw coal carbonization activation co-production process and its system

A raw coal and process technology, applied in the field of raw coal carbonization activation co-production process and its systems, can solve the problems of high production cost of activated carbon and ineffective utilization of raw coal, achieve full and efficient utilization, avoid environmental pollution problems, and reduce comprehensive costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

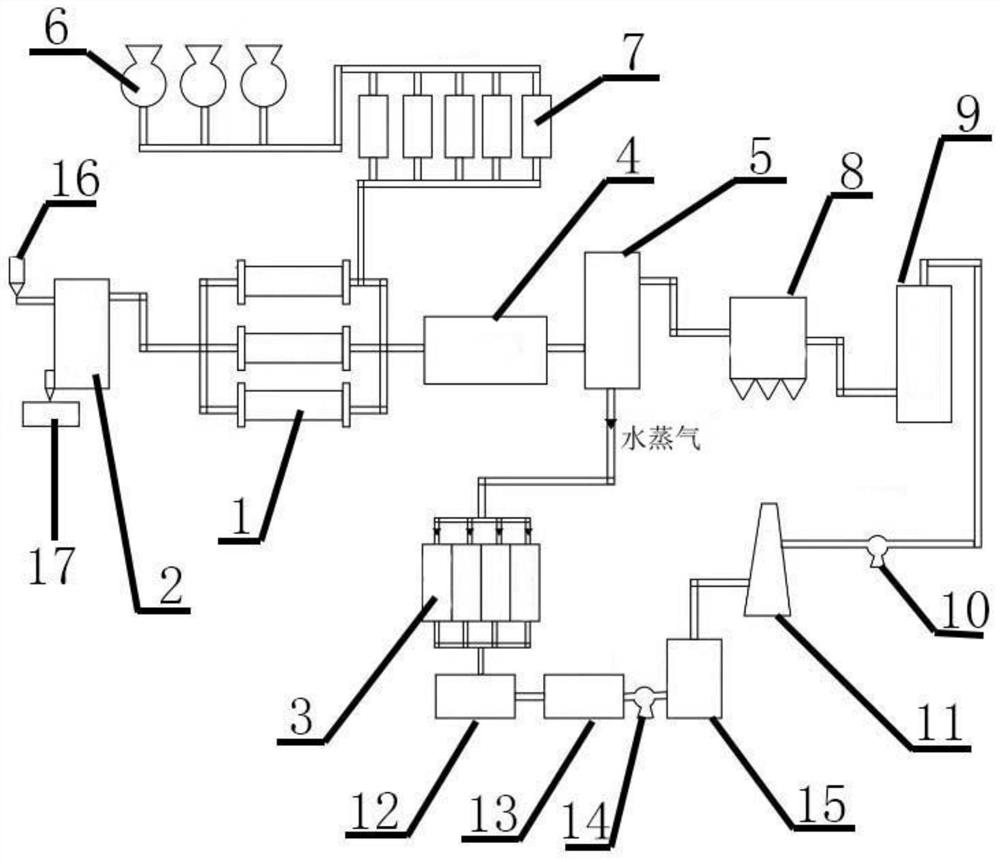

[0032] Such as figure 1 The shown a kind of raw coal carbonization activation cogeneration system comprises raw coal carbonization furnace 1, fluidized bed activation reactor 2, Sleep activation furnace 3 and raw coal pretreatment device, and described raw coal carbonization furnace 1 is connected with described fluidized bed respectively The activation reactor 2 is connected with the Sleep activation furnace 3, and the raw coal pretreatment device is connected with the raw coal carbonization furnace 1; the fluidized bed activation reactor 2 is a continuous self-heating activation device, which can produce activated carbon while Continuous production temperature 800°C, calorific value 900kcal / Nm 3 The left and right hot gas, the gas outlet of the fluidized bed activation reactor 2 communicates with the fuel inlet of the raw coal carbonization furnace 1 to realize the energy supply of the raw coal carbonization furnace 1 .

[0033] A first incineration chamber 4 and a waste he...

Embodiment 2

[0039] In addition to the technical solution of Example 1, the technical solution of this embodiment also includes the following technical solution: the gas output port of the fluidized bed activation reactor 2 and the gas output port of the raw coal carbonization furnace 1 are connected with the Sleep activation furnace 3 respectively. The combustion chambers are connected by valves. Through the above technical scheme, when the heat of the Sleep activation furnace is insufficient and the temperature increase is limited, the heat can be supplemented by activating the gas in the fluidized bed activation reactor or carbonizing the coal gas in the raw coal carbonization furnace to realize the rapid adjustment / switching of the Sleep, ensuring Continuous and high-quality production of activated carbon in the Sleep activation furnace.

Embodiment 3

[0041] A raw coal carbonization activation co-production process, said process is implemented using the system described in Example 1; said process comprises the steps of:

[0042] The raw coal is sent into the raw coal carbonization furnace 1 after being pulverized and briquetted by the pulverizer 6 and the briquetting machine 7, and the carbonized material with a particle size of 0.5-6 mm produced by carbonization is sent into the fluidized bed activation reactor 2 Activate to form the first activated carbon, and send the carbonized material with a particle size of 3-12 mm into the Sleep activation furnace 3 for activation to form the second activated carbon;

[0043] The raw coal is sent into the raw coal carbonization furnace 1 after being pulverized and briquetted to be carbonized and the raw coal gas is produced by-product at a temperature of about 280°C; the raw coal gas produced in the three raw coal carbonization furnaces 1 is sent to the first incineration chamber In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com