Method for charring biomass and upgrading brown coal

A biomass charcoal and lignite technology, which is applied in the fields of biofuels, special forms of dry distillation, coke ovens, etc., can solve the problems such as the latent heat of dry distillation gas can not meet the heat demand of the carbonization system, the economic benefits are reduced, and there is no economic value, and the reliability is achieved. High, reduce pollution discharge, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for biomass carbonization and lignite upgrading, wherein the drying process and carbonization process are completed in different equipment;

[0021] In the drying process, the hot waste gas flows in the same direction as the materials in the drying furnace, the hot drying gas and the gas produced by drying, the hot drying gas dries the materials through direct contact, and the hot waste gas passes through the thermal radiation. way to heat the material;

[0022] In the carbonization process, the generated hot waste gas and the material in the carbonization furnace flow in the opposite direction, the material in the carbonization furnace and the retort gas flow in the same direction, and the hot waste gas heats the material through heat radiation.

[0023] Due to the separation of drying and carbonization, the condensed liquid produced by drying contains less aromatic compounds, making the vinegar liquid more pure, easy to recycle, high economic value, and reduc...

Embodiment 2

[0025] As a further optimization of Example 1, the hot drying gas is heated, cooled, and cyclically heated to dry the material and condense and recover the dried gas; the dry distillation gas directly enters the incinerator for complete incineration, and the tar is recovered without cooling , the high-temperature exhaust gas after incineration is used as the heat source carrier of the carbonization furnace and the drying furnace, and the excess heat is made into steam by the waste heat boiler or used for other uses.

[0026] All the retort gas is introduced into the incinerator for incineration, and the gas, tar and other impurities in the retort gas are completely decomposed and burned in the incinerator, without the discharge of waste liquid and waste solid; the latent heat of the retort gas completely turns into sensible heat, and the heat generated is large , to meet the heat demand of the whole system, and the rich part can be used for other purposes, achieving better econ...

Embodiment 3

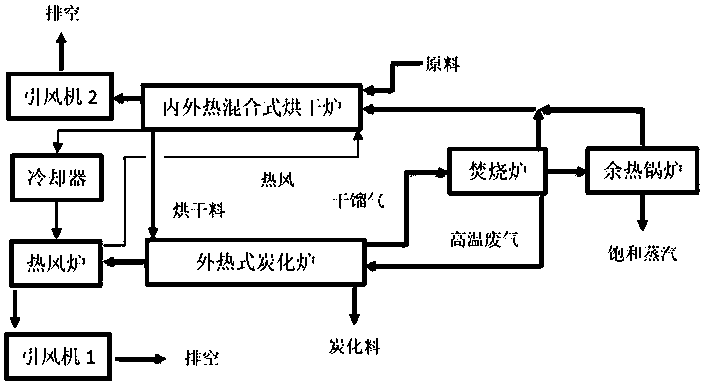

[0028] Such as figure 1 As shown, as the specific selection of equipment in Example 1, the equipment in the drying process is an internal and external hybrid drying converter, and the material passes through the tube side or shell side of the drying furnace. When the material is in the tube side of the drying furnace The hot exhaust gas is on the shell side, and when the material is on the shell side, the hot exhaust gas is on the tube side, and the dried material enters the carbonization process; the equipment in the carbonization process is an externally heated carbonization converter, and the material passes through the tube side or shell side of the carbonization converter , when the material is on the tube side of the carbonization converter, the hot exhaust gas is on the shell side, and when the material is on the shell side, the hot exhaust gas is on the tube side.

[0029] Drying adopts internal and external hybrid drying converter to improve drying efficiency and redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com